Multi-Media Unit

Page

Issue Date Revisions

Page

Declaration of Conformity

Page

Table of Contents

Index

Frequent Questions

Find-it

Page

Page

Not new to Multi-Media?

Overview

New to Multi-Media?

Software

Communications

Walking Through

Cameras

Other Hardware

Powering-up the Multi-Media unit

Admin and View Software

Using Admin, add a site

Start Admin to create a Multi database

Log on to a Multi database, or create one using Admin

Database for Multi

Add information about the connection, and save it

Type of Connection

Running View

About connections

Log on to View

Testing a Connection

Test the connection use View to run a Maintenance session

Where To, Next?

For More Information

Background information

Road map to field work

Unpacking the Unit

Audience

Please do not remove factory seals on a Multi-Media unit

Printed matter

Rear Panel Reference

Item, one of each, unless otherwise noted

Temperature

USB port and Printer port

Reporting the Installation

Powering the Multi-Media Unit

Powering Up and Down

Nominal storage* camera-day time† minute

Connecting a Camera

Unit Recovery

Rapid Dome or Rapid Dome Gold dome systems

Reference

LocalView

Securing a camera

Hardware

Monitors

To enable the locking of a LocalView functions

LocalView help on operator’s PC

Recording rate fps lowest cycle time sec

To change a LocalView password

Network Connection

Overview

For a network without Dhcp

Using LocalView Onsite

To assign an IP address to a unit using LocalView

What next?

To connect a null-modem cable

Using a PC Onsite

To setup a terminal program

Null-modem cable comes with your Multi-Media unit

Multi-Media Unit Installation Instructions

Parameter Value

Windows Click Start and point to … … then click

Hypertrm.exe icon

To use the Multi-Media Shell

Multi Shell Reference

Field Name Default Address Shell command

Command Result

None, port1, port2, or internal

Dial-up Connection

To return to the Multi-Media Shell after a time out

Modem Reference

Field Testing a Connection

Damaged or Missing Goods

Upgrading Unit Software

Upgrade CD-ROM

To upgrade a Multi-Media unit’s software, onsite

Multi-Media unit without a CD-RW drive

Please continue

Multi Software

Road map for using Multi software to obtain video

Why check a connection?

To install Multi software

Some versions of Windows need you to restart the PC

Using Admin

Running Admin

Double-duty logon dialog

Obtaining a Multi Db

After adding security

Click Save and Close To name a site

Site identification checklist

Adding Site Information

Confirmation

Record of a Dial-up Connection

Dealing with connections

To make a record of a dial-up connection

Dealing with dial-up confusion

IP Address is mandatory for a network connection

Record of a Network Connection

To make a record of a network connection

Checking for video

Using View to Connect

Firewall reference

To run a maintenance session on a Rapid Eye site

Testing a Connection Maintenance

Using Maintenance

Logging on to View

Time zone

Testing a Connection Time

Crucial settings for reporting on video of events

Conflicting time zones

To indicate the time zone of a Multi-Media unit

Time zone is set on a unit-by-unit basis

Clock Automatic setting

To respond to a notification of conflicting time zones

To set a unit’s clock manually, using a PC’s

Auto-synch statistics

Testing a Connection Camera

Video tab in Maintenance session video feed adjustments

To obtain video from a live video session

To configure a Rapid Eye site’s cameras

Obtaining Video

Results

What Next

Please continue

Selecting a microphone

Audio at a Multi-Media Site

Microphones

Placing a microphone

Checking for Audio Interference

Preventive measures

At View Operator’s PC

To enable talking to a site

Audio for Operators

To send and receive audio offsite

To enable audio for use onsite, by LocalView

To disable audio for LocalView

Securing a Multi-Media unit

To secure the unit

Hard Disk Report

Unit Hard Disk

Detachable Camera I/O

To detach the sub-panel

Hardware Options

Handle on mounted hard disk

Daisy-chaining Domes

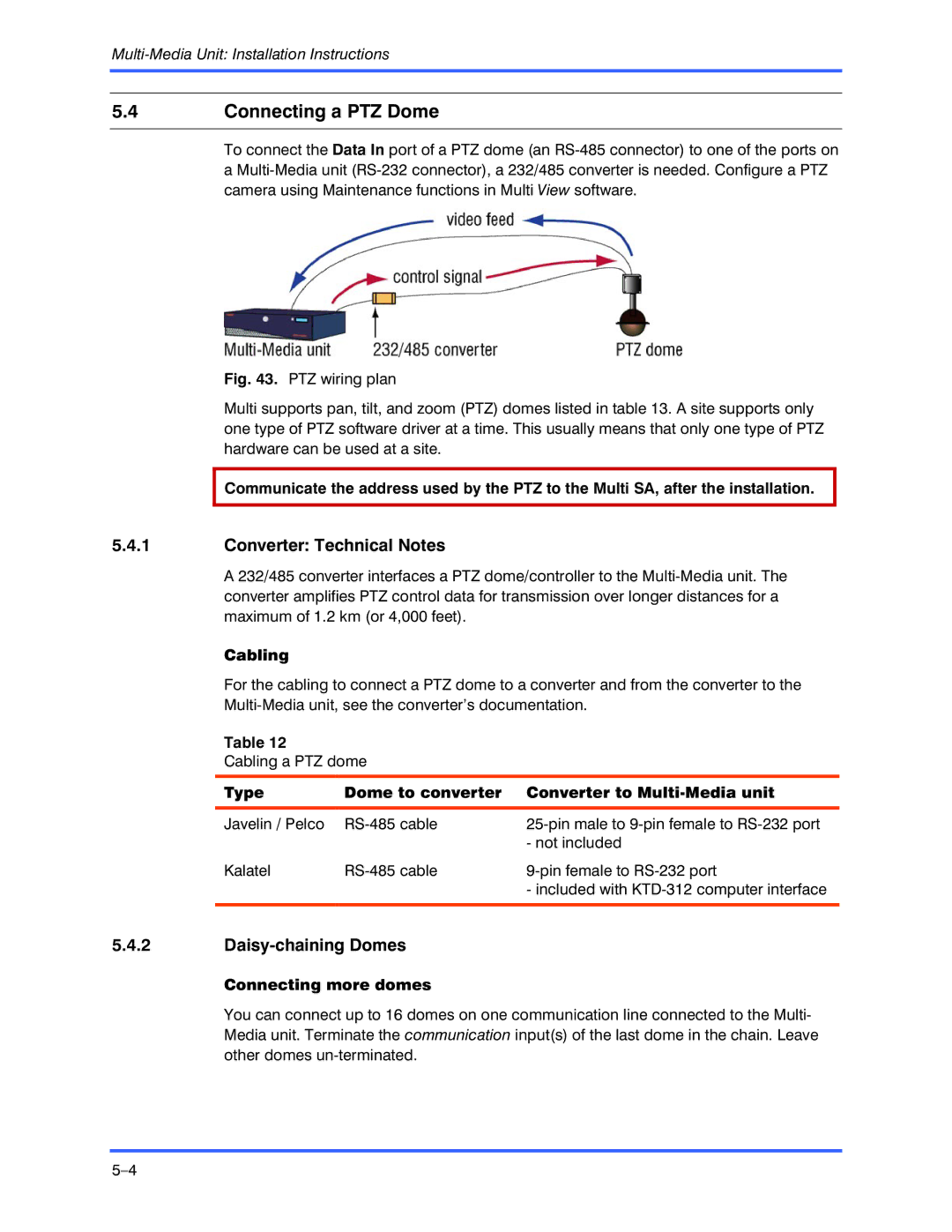

Connecting a PTZ Dome

Converter Technical Notes

Configuring PTZ

Driver name Baud rate Supported controller/dome Alphabetical

Alarm Sensors

Inputs for Sensors

No normally open

Input Technical Notes

Inputs to a Multi-Media unit, used by hardware devices

NC normally closed

Control Outputs

System Monitoring

Alarm panel

Software setup To set the Fault Relay to trigger

External Modems

Configuring POS

Point of Sale Hardware

At unit, connected to a network

Serial connection Connect only to serial port COM

Using null-modem cable for installation of Multi-Media unit

Port Use Restrictions

USB port and Parallel port

Please continue

Supporting an Installation

Cannot connect to Multi-Media unit, using View

See also

Background

Frequently asked question Section No video is reaching View

Planning

Coaxial Cable

Grounding

Hum bar

Electrical Interference

Lighting

Triaxial cable

Find-it

Knowledge Base

Tables

Use the same database created earlier, using Admin see on p

Illustrations

Dial-up Networking

More FAQs

More FAQs Find-it

Network Connection

More FAQs Find-it

Site Information Checklist

Organization personnel Personnel Name, telephone #, email

Site definition Rapid Eye site… Identification

Communications to unit Connection Value

Audio Microphone type Speaker type Comments

Site Information Checklist Find-it

Sensor hardware Input Type NO, NC, EOL Description

Site Information Checklist Find-it

Multi-Media Unit Installation Instructions

Index

Multi-Media Unit Installation Instructions

Index

Page

Page

Page

Page

Honeywell Security Espana

Honeywell Security France

Honeywell Security Italia SpA

Honeywell Security House Netherlands