EXCEL 10 W7761A INPUT/OUTPUT DEVICE

ML6161 | 2.2 VA | TRADELINE® |

Damper Actuator |

| Catalog |

R8242A | 21.0 VA | TRADELINE® |

Contactor for fan |

| Catalog |

M6410A Steam | 0.7 VA | TRADELINE® |

Heating Coil Valve |

| Catalog, 0.32A at 24 Vac |

TOTAL: 29.9 VA

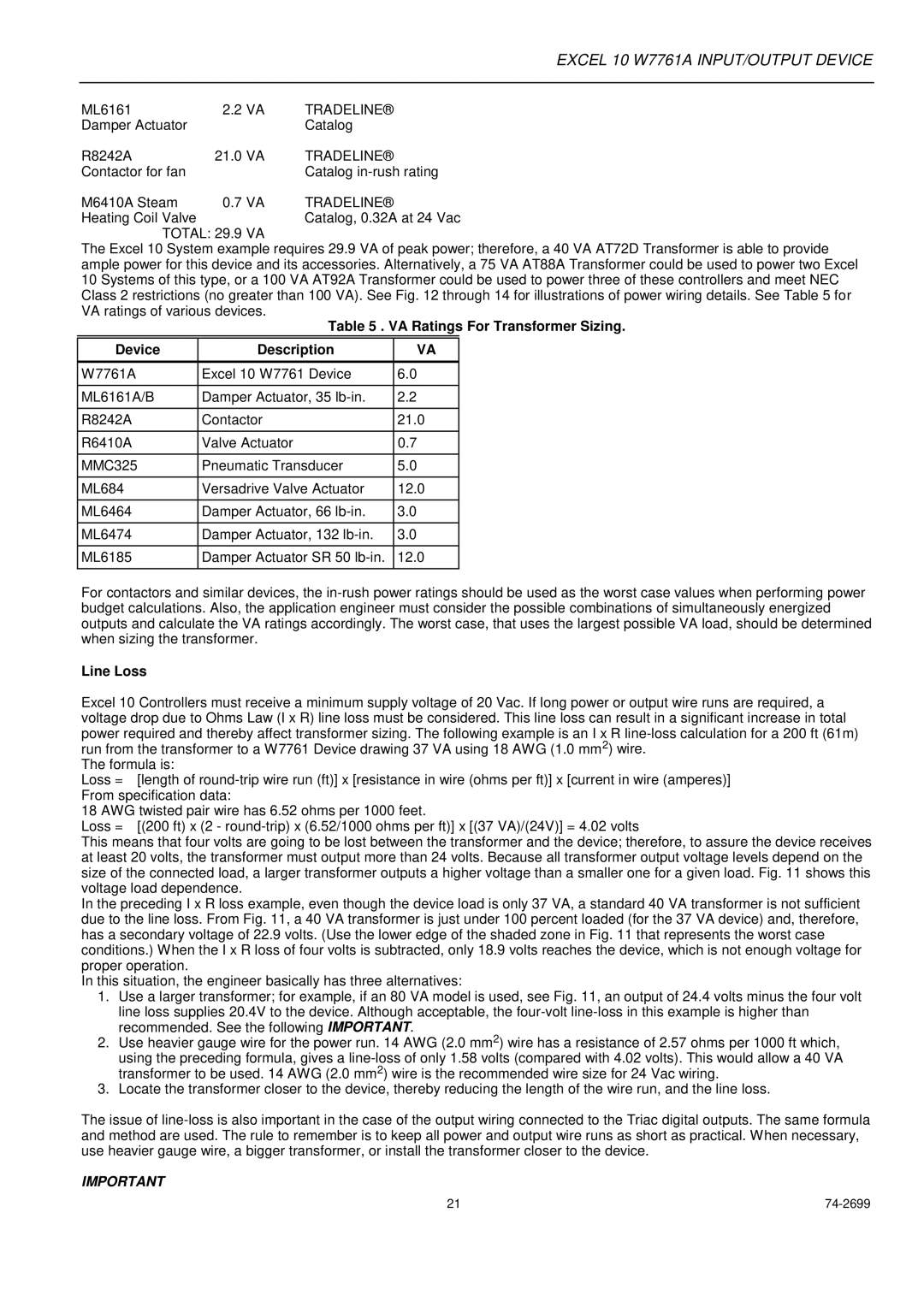

The Excel 10 System example requires 29.9 VA of peak power; therefore, a 40 VA AT72D Transformer is able to provide ample power for this device and its accessories. Alternatively, a 75 VA AT88A Transformer could be used to power two Excel 10 Systems of this type, or a 100 VA AT92A Transformer could be used to power three of these controllers and meet NEC Class 2 restrictions (no greater than 100 VA). See Fig. 12 through 14 for illustrations of power wiring details. See Table 5 for VA ratings of various devices.

Table 5 . VA Ratings For Transformer Sizing.

Device | Description | VA |

|

|

|

W7761A | Excel 10 W7761 Device | 6.0 |

|

|

|

ML6161A/B | Damper Actuator, 35 | 2.2 |

|

|

|

R8242A | Contactor | 21.0 |

|

|

|

R6410A | Valve Actuator | 0.7 |

|

|

|

MMC325 | Pneumatic Transducer | 5.0 |

|

|

|

ML684 | Versadrive Valve Actuator | 12.0 |

|

|

|

ML6464 | Damper Actuator, 66 | 3.0 |

|

|

|

ML6474 | Damper Actuator, 132 | 3.0 |

|

|

|

ML6185 | Damper Actuator SR 50 | 12.0 |

|

|

|

For contactors and similar devices, the

Line Loss

Excel 10 Controllers must receive a minimum supply voltage of 20 Vac. If long power or output wire runs are required, a voltage drop due to Ohms Law (I x R) line loss must be considered. This line loss can result in a significant increase in total power required and thereby affect transformer sizing. The following example is an I x R

The formula is:

Loss = [length of

18 AWG twisted pair wire has 6.52 ohms per 1000 feet.

Loss = [(200 ft) x (2 -

This means that four volts are going to be lost between the transformer and the device; therefore, to assure the device receives at least 20 volts, the transformer must output more than 24 volts. Because all transformer output voltage levels depend on the size of the connected load, a larger transformer outputs a higher voltage than a smaller one for a given load. Fig. 11 shows this voltage load dependence.

In the preceding I x R loss example, even though the device load is only 37 VA, a standard 40 VA transformer is not sufficient due to the line loss. From Fig. 11, a 40 VA transformer is just under 100 percent loaded (for the 37 VA device) and, therefore, has a secondary voltage of 22.9 volts. (Use the lower edge of the shaded zone in Fig. 11 that represents the worst case conditions.) When the I x R loss of four volts is subtracted, only 18.9 volts reaches the device, which is not enough voltage for proper operation.

In this situation, the engineer basically has three alternatives:

1.Use a larger transformer; for example, if an 80 VA model is used, see Fig. 11, an output of 24.4 volts minus the four volt line loss supplies 20.4V to the device. Although acceptable, the

2.Use heavier gauge wire for the power run. 14 AWG (2.0 mm2) wire has a resistance of 2.57 ohms per 1000 ft which,

using the preceding formula, gives a

3.Locate the transformer closer to the device, thereby reducing the length of the wire run, and the line loss.

The issue of

IMPORTANT

21 |