SAFETY INSPECTION

SECTION 2 | SAFETY INSPECTION |

|

|

Section 2 - Safety Inspection - includes the following:

Safety Inspection Checklist

Troubleshooting

Maintenance

NOTE: Every six (6) months, take your wheelchair to a qualified technician for a thorough inspection and servicing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your wheelchair. To operate properly and safely, your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your wheelchair. Clean upholstery with mild soap and water or spray disinfectant using a sponge. DO NOT use bleach or wash in a washing machine.

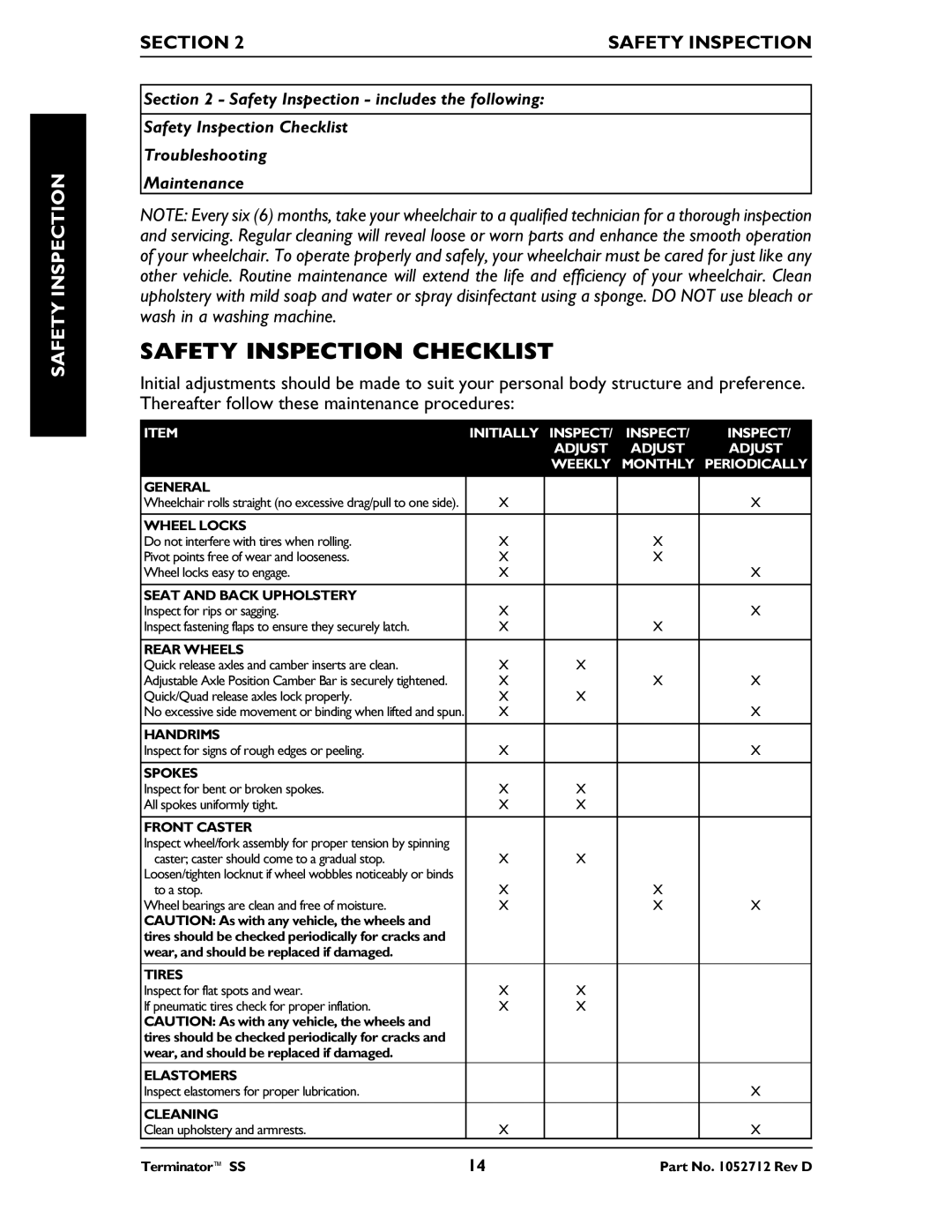

SAFETY INSPECTION CHECKLIST

Initial adjustments should be made to suit your personal body structure and preference. Thereafter follow these maintenance procedures:

ITEM | INITIALLY | INSPECT/ | INSPECT/ | INSPECT/ |

|

| ADJUST | ADJUST | ADJUST |

|

| WEEKLY | MONTHLY PERIODICALLY | |

|

|

|

|

|

GENERAL |

|

|

|

|

Wheelchair rolls straight (no excessive drag/pull to one side). | X |

|

| X |

|

|

|

|

|

WHEEL LOCKS |

|

|

|

|

Do not interfere with tires when rolling. | X |

| X |

|

Pivot points free of wear and looseness. | X |

| X |

|

Wheel locks easy to engage. | X |

|

| X |

|

|

|

|

|

SEAT AND BACK UPHOLSTERY |

|

|

|

|

Inspect for rips or sagging. | X |

|

| X |

Inspect fastening flaps to ensure they securely latch. | X |

| X |

|

|

|

|

|

|

REAR WHEELS |

|

|

|

|

Quick release axles and camber inserts are clean. | X | X |

|

|

Adjustable Axle Position Camber Bar is securely tightened. | X |

| X | X |

Quick/Quad release axles lock properly. | X | X |

|

|

No excessive side movement or binding when lifted and spun. | X |

|

| X |

|

|

|

|

|

HANDRIMS |

|

|

|

|

Inspect for signs of rough edges or peeling. | X |

|

| X |

|

|

|

|

|

SPOKES |

|

|

|

|

Inspect for bent or broken spokes. | X | X |

|

|

All spokes uniformly tight. | X | X |

|

|

|

|

|

|

|

FRONT CASTER |

|

|

|

|

Inspect wheel/fork assembly for proper tension by spinning |

|

|

|

|

caster; caster should come to a gradual stop. | X | X |

|

|

Loosen/tighten locknut if wheel wobbles noticeably or binds |

|

|

|

|

to a stop. | X |

| X |

|

Wheel bearings are clean and free of moisture. | X |

| X | X |

CAUTION: As with any vehicle, the wheels and |

|

|

|

|

tires should be checked periodically for cracks and |

|

|

|

|

wear, and should be replaced if damaged. |

|

|

|

|

|

|

|

|

|

TIRES |

|

|

|

|

Inspect for flat spots and wear. | X | X |

|

|

If pneumatic tires check for proper inflation. | X | X |

|

|

CAUTION: As with any vehicle, the wheels and |

|

|

|

|

tires should be checked periodically for cracks and |

|

|

|

|

wear, and should be replaced if damaged. |

|

|

|

|

ELASTOMERS |

|

|

|

|

Inspect elastomers for proper lubrication. |

|

|

| X |

|

|

|

|

|

CLEANING |

|

|

|

|

Clean upholstery and armrests. | X |

|

| X |

|

|

|

|

|

Terminator™ SS | 14 | Part No. 1052712 Rev D |