Understanding print media guidelines

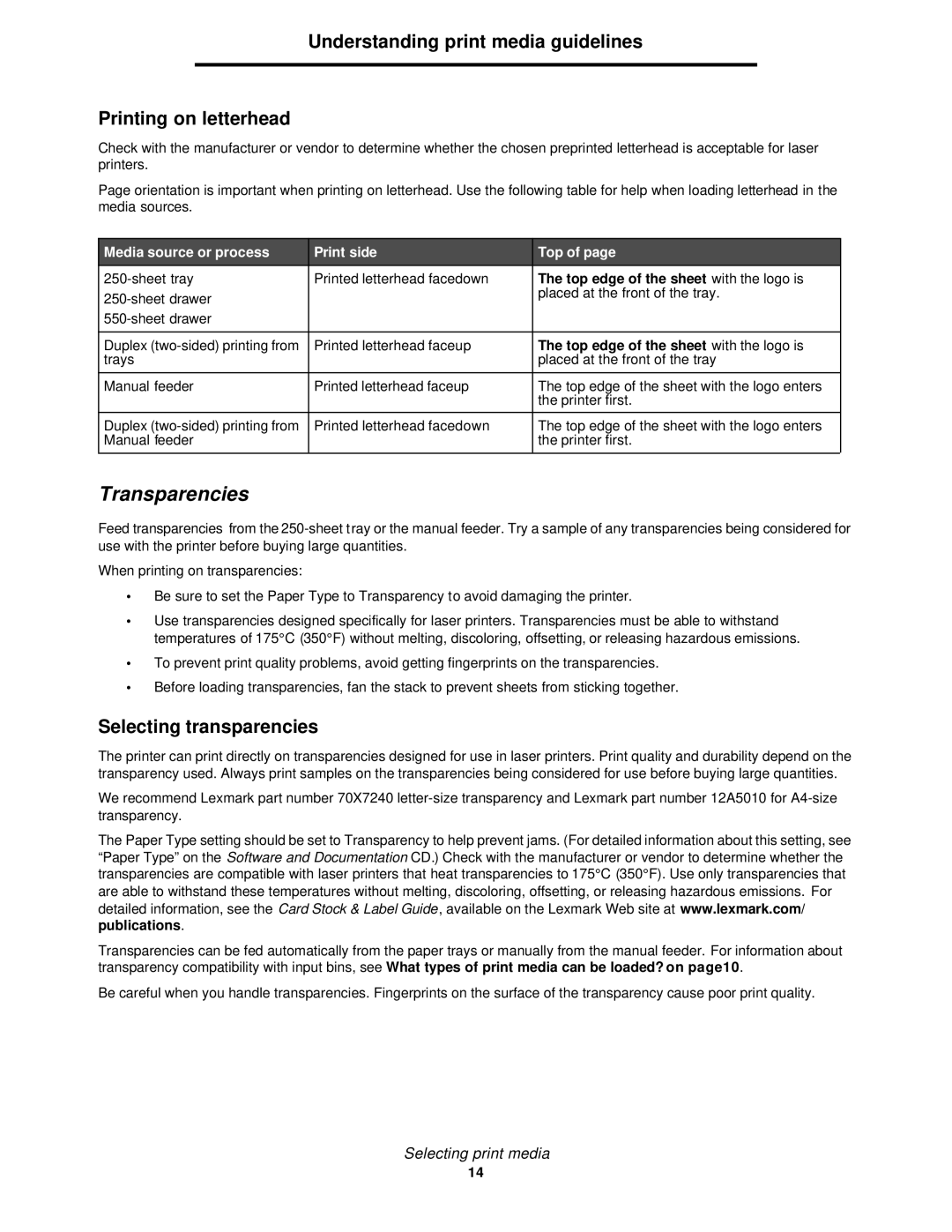

Printing on letterhead

Check with the manufacturer or vendor to determine whether the chosen preprinted letterhead is acceptable for laser printers.

Page orientation is important when printing on letterhead. Use the following table for help when loading letterhead in the media sources.

Media source or process

Duplex

Manual feeder

Duplex

Print side

Printed letterhead facedown

Printed letterhead faceup

Printed letterhead faceup

Printed letterhead facedown

Top of page

The top edge of the sheet with the logo is placed at the front of the tray.

The top edge of the sheet with the logo is placed at the front of the tray

The top edge of the sheet with the logo enters the printer first.

The top edge of the sheet with the logo enters the printer first.

Transparencies

Feed transparencies from the

When printing on transparencies:

•Be sure to set the Paper Type to Transparency to avoid damaging the printer.

•Use transparencies designed specifically for laser printers. Transparencies must be able to withstand temperatures of 175°C (350°F) without melting, discoloring, offsetting, or releasing hazardous emissions.

•To prevent print quality problems, avoid getting fingerprints on the transparencies.

•Before loading transparencies, fan the stack to prevent sheets from sticking together.

Selecting transparencies

The printer can print directly on transparencies designed for use in laser printers. Print quality and durability depend on the transparency used. Always print samples on the transparencies being considered for use before buying large quantities.

We recommend Lexmark part number 70X7240

The Paper Type setting should be set to Transparency to help prevent jams. (For detailed information about this setting, see “Paper Type” on the Software and Documentation CD.) Check with the manufacturer or vendor to determine whether the transparencies are compatible with laser printers that heat transparencies to 175°C (350°F). Use only transparencies that are able to withstand these temperatures without melting, discoloring, offsetting, or releasing hazardous emissions. For detailed information, see the Card Stock & Label Guide, available on the Lexmark Web site at www.lexmark.com/ publications.

Transparencies can be fed automatically from the paper trays or manually from the manual feeder. For information about transparency compatibility with input bins, see What types of print media can be loaded? on page10.

Be careful when you handle transparencies. Fingerprints on the surface of the transparency cause poor print quality.

Selecting print media

14