|

|

|

|

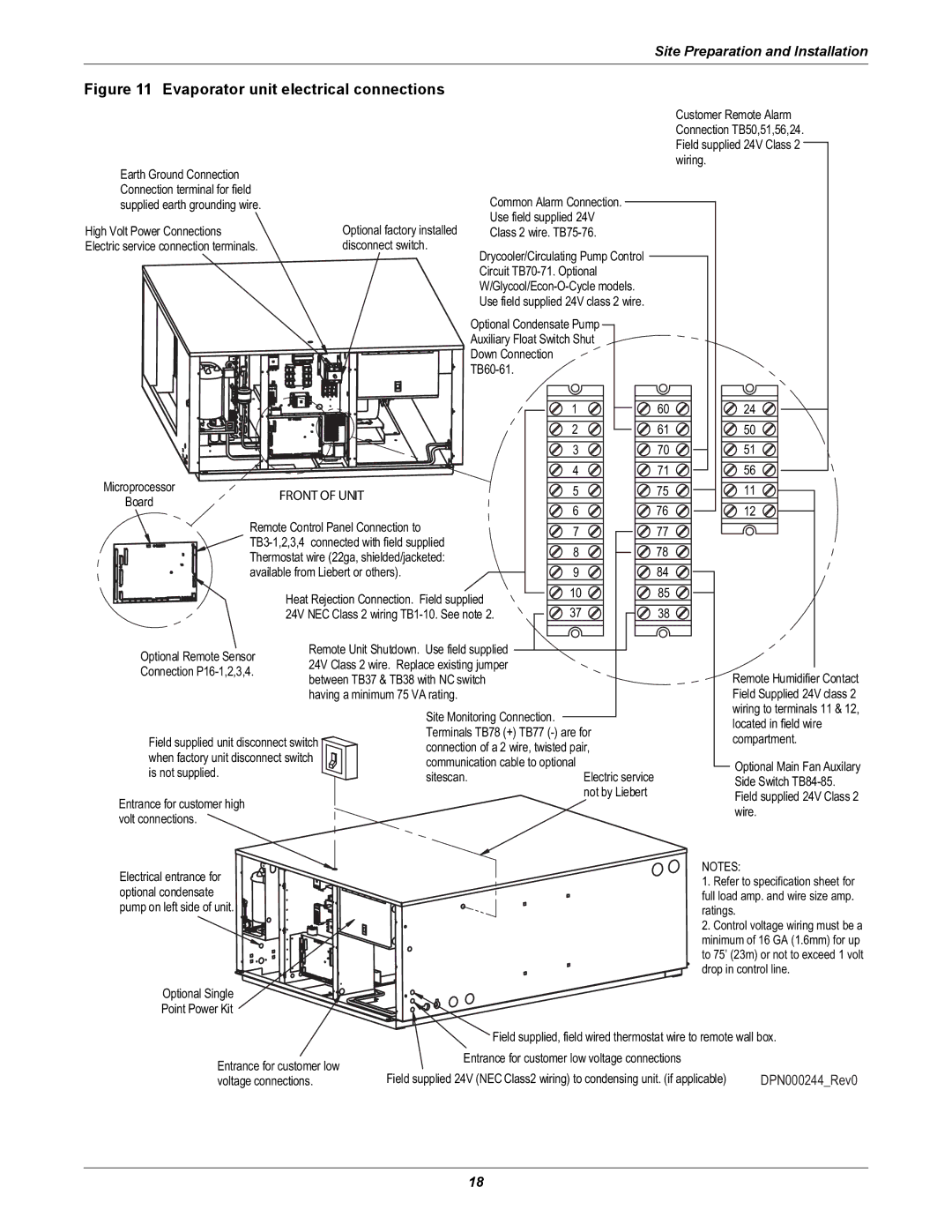

| Site Preparation and Installation | |

Figure 11 | Evaporator unit electrical connections |

|

|

|

| |

|

|

|

|

|

| Customer Remote Alarm |

|

|

|

|

|

| Connection TB50,51,56,24. |

|

|

|

|

|

| Field supplied 24V Class 2 |

Earth Ground Connection |

|

|

|

| wiring. | |

|

|

|

|

| ||

Connection terminal for field |

| Common Alarm Connection. |

|

| ||

supplied earth grounding wire. |

|

|

| |||

High Volt Power Connections | Optional factory installed | Use field supplied 24V |

|

| ||

Class 2 wire. |

|

| ||||

Electric service connection terminals. | disconnect switch. | Drycooler/Circulating Pump Control |

|

| ||

|

|

|

|

| ||

|

|

| Circuit |

|

| |

|

|

|

|

| ||

|

|

| Use field supplied 24V class 2 wire. |

|

| |

|

|

| Optional Condensate Pump |

|

| |

|

|

| Auxiliary Float Switch Shut |

|

| |

|

|

| Down Connection |

|

|

|

|

|

|

|

|

| |

|

|

|

| 1 | 60 | 24 |

|

|

|

| 2 | 61 | 50 |

|

|

|

| 3 | 70 | 51 |

Microprocessor |

|

| 4 | 71 | 56 | |

FRONT OF UNIT |

| 5 | 75 | 11 | ||

Board |

|

| 6 | 76 | 12 | |

| Remote Control Panel Connection to |

| ||||

|

| 7 | 77 |

| ||

|

|

| ||||

|

| 8 | 78 |

| ||

| Thermostat wire (22ga, shielded/jacketed: |

|

| |||

| available from Liebert or others). |

| 9 | 84 |

| |

|

| Heat Rejection Connection. Field supplied | 10 | 85 |

| |

|

| 37 | 38 |

| ||

|

| 24V NEC Class 2 wiring |

| |||

Optional Remote Sensor | Remote Unit Shutdown. Use field supplied |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||||

24V Class 2 wire. Replace existing jumper |

|

|

|

|

|

| |||||

Connection |

|

|

|

|

| Remote Humidifier Contact | |||||

between TB37 & TB38 with NC switch |

|

|

|

|

| ||||||

|

|

|

|

|

| ||||||

| having a minimum 75 VA rating. |

|

|

|

|

| Field Supplied 24V class 2 | ||||

|

|

| Site Monitoring Connection. |

|

|

|

|

|

| wiring to terminals 11 & 12, | |

|

|

|

|

|

|

|

|

| located in field wire | ||

|

|

| Terminals TB78 (+) TB77 |

|

| ||||||

Field supplied unit disconnect switch |

|

|

| compartment. | |||||||

| connection of a 2 wire, twisted pair, |

|

| ||||||||

when factory unit disconnect switch |

|

|

|

| |||||||

| communication cable to optional |

|

|

|

|

| Optional Main Fan Auxilary | ||||

|

|

|

|

|

| ||||||

is not supplied. |

|

| Electric service |

|

| ||||||

|

| sitescan. |

|

| Side Switch | ||||||

|

|

|

| ||||||||

|

|

|

|

| |||||||

Entrance for customer high |

|

|

|

|

| not by Liebert |

|

| Field supplied 24V Class 2 | ||

|

|

|

|

|

|

|

|

|

| wire. | |

volt connections. |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| NOTES: | |||

Electrical entrance for |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| 1. Refer to specification sheet for | |||

optional condensate |

|

|

|

|

|

|

|

| full load amp. and wire size amp. | ||

pump on left side of unit. |

|

|

|

|

|

|

|

| ratings. | ||

|

|

|

|

|

|

|

|

| 2. Control voltage wiring must be a | ||

|

|

|

|

|

|

|

|

| minimum of 16 GA (1.6mm) for up | ||

|

|

|

|

|

|

|

|

| to 75’ (23m) or not to exceed 1 volt | ||

|

|

|

|

|

|

|

|

| drop in control line. | ||

Optional Single |

|

|

|

|

|

|

|

|

|

|

|

Point Power Kit |

|

|

|

|

|

|

|

|

|

|

|

| Field supplied, field wired thermostat wire to remote wall box. | ||

Entrance for customer low | Entrance for customer low voltage connections |

| |

Field supplied 24V (NEC Class2 wiring) to condensing unit. (if applicable) | DPN000244_Rev0 | ||

voltage connections. | |||

18