Troubleshooting

8.0TROUBLESHOOTING

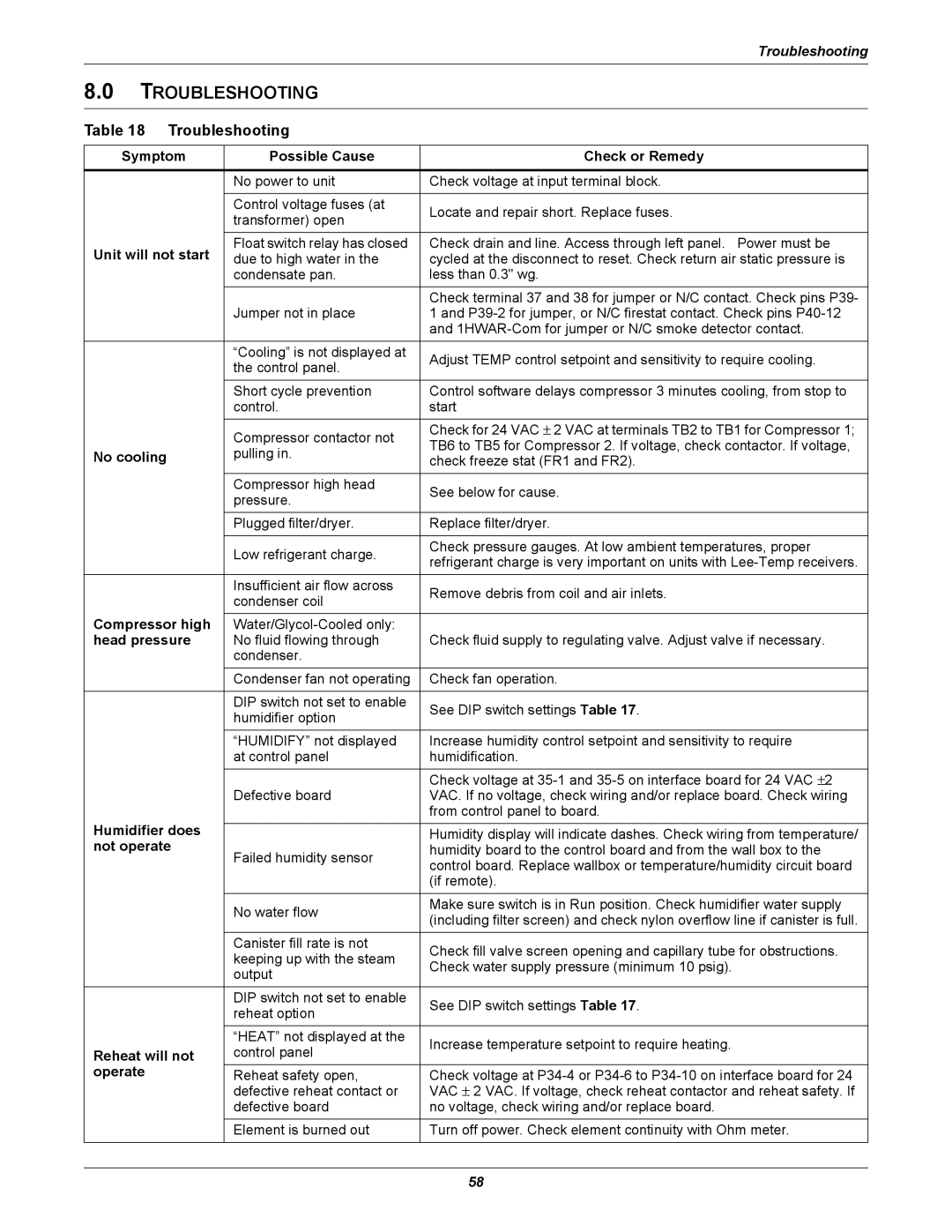

Table 18 Troubleshooting

Symptom | Possible Cause | Check or Remedy | |

|

|

| |

| No power to unit | Check voltage at input terminal block. | |

|

|

| |

| Control voltage fuses (at | Locate and repair short. Replace fuses. | |

| transformer) open | ||

|

| ||

Unit will not start | Float switch relay has closed | Check drain and line. Access through left panel. Power must be | |

due to high water in the | cycled at the disconnect to reset. Check return air static pressure is | ||

| condensate pan. | less than 0.3" wg. | |

|

| Check terminal 37 and 38 for jumper or N/C contact. Check pins P39- | |

| Jumper not in place | 1 and | |

|

| and | |

| “Cooling” is not displayed at | Adjust TEMP control setpoint and sensitivity to require cooling. | |

| the control panel. | ||

|

| ||

| Short cycle prevention | Control software delays compressor 3 minutes cooling, from stop to | |

| control. | start | |

| Compressor contactor not | Check for 24 VAC ± 2 VAC at terminals TB2 to TB1 for Compressor 1; | |

| TB6 to TB5 for Compressor 2. If voltage, check contactor. If voltage, | ||

No cooling | pulling in. | ||

check freeze stat (FR1 and FR2). | |||

|

|

| |

| Compressor high head | See below for cause. | |

| pressure. | ||

|

| ||

| Plugged filter/dryer. | Replace filter/dryer. | |

|

|

| |

| Low refrigerant charge. | Check pressure gauges. At low ambient temperatures, proper | |

| refrigerant charge is very important on units with | ||

|

| ||

| Insufficient air flow across | Remove debris from coil and air inlets. | |

| condenser coil | ||

|

| ||

Compressor high |

| ||

head pressure | No fluid flowing through | Check fluid supply to regulating valve. Adjust valve if necessary. | |

| condenser. |

| |

| Condenser fan not operating | Check fan operation. | |

|

|

| |

| DIP switch not set to enable | See DIP switch settings Table 17. | |

| humidifier option | ||

|

| ||

| “HUMIDIFY” not displayed | Increase humidity control setpoint and sensitivity to require | |

| at control panel | humidification. | |

|

| Check voltage at | |

| Defective board | VAC. If no voltage, check wiring and/or replace board. Check wiring | |

|

| from control panel to board. | |

Humidifier does |

|

| |

| Humidity display will indicate dashes. Check wiring from temperature/ | ||

not operate | Failed humidity sensor | humidity board to the control board and from the wall box to the | |

| control board. Replace wallbox or temperature/humidity circuit board | ||

|

| ||

|

| (if remote). | |

|

|

| |

| No water flow | Make sure switch is in Run position. Check humidifier water supply | |

| (including filter screen) and check nylon overflow line if canister is full. | ||

|

| ||

| Canister fill rate is not | Check fill valve screen opening and capillary tube for obstructions. | |

| keeping up with the steam | ||

| Check water supply pressure (minimum 10 psig). | ||

| output | ||

|

| ||

|

|

| |

| DIP switch not set to enable | See DIP switch settings Table 17. | |

| reheat option | ||

|

| ||

| “HEAT” not displayed at the | Increase temperature setpoint to require heating. | |

Reheat will not | control panel | ||

| |||

operate |

|

| |

Reheat safety open, | Check voltage at | ||

| defective reheat contact or | VAC ± 2 VAC. If voltage, check reheat contactor and reheat safety. If | |

| defective board | no voltage, check wiring and/or replace board. | |

| Element is burned out | Turn off power. Check element continuity with Ohm meter. | |

|

|

|

58