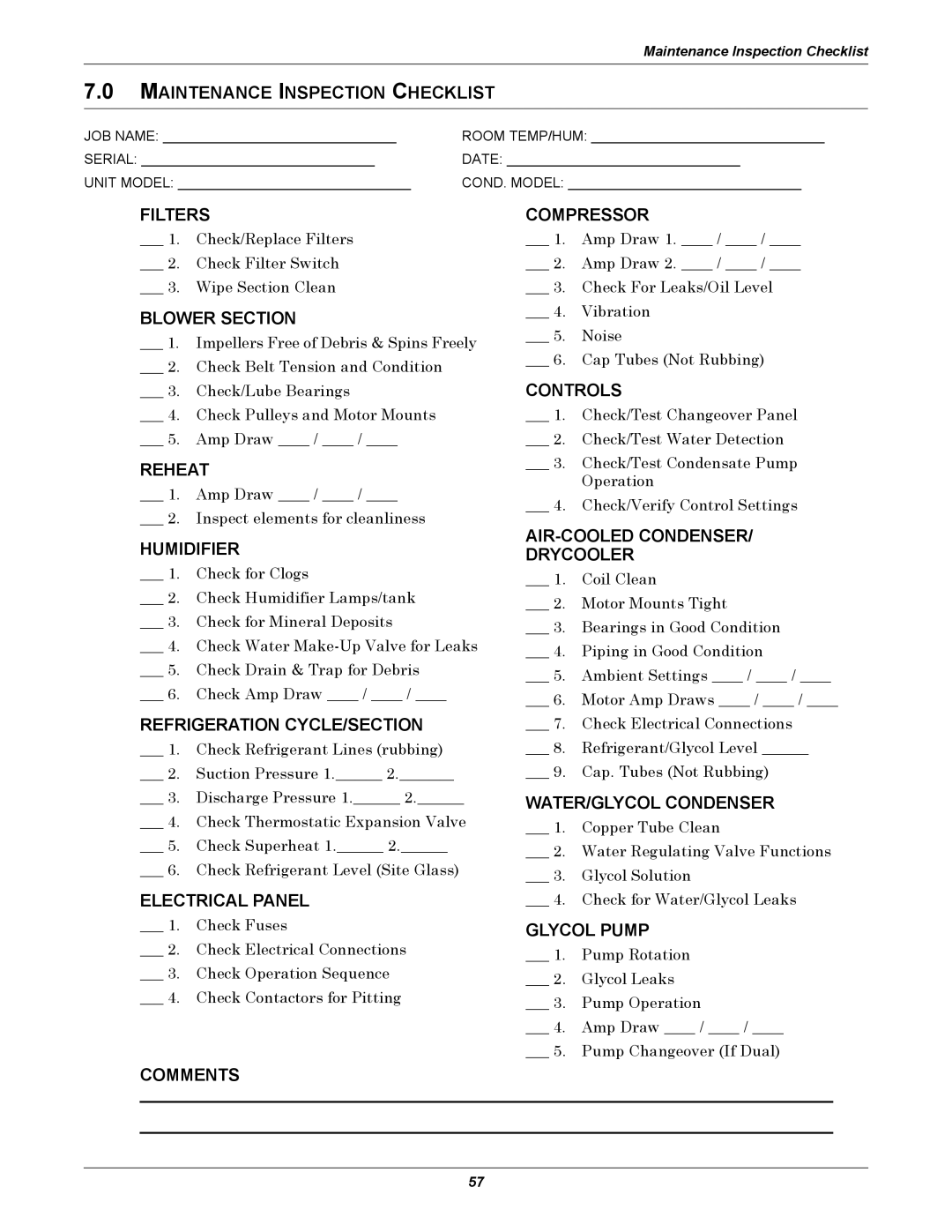

Maintenance Inspection Checklist

7.0MAINTENANCE INSPECTION CHECKLIST

JOB NAME: ______________________________ | ROOM TEMP/HUM: ______________________________ |

SERIAL: ______________________________ | DATE: ______________________________ |

UNIT MODEL: ______________________________ | COND. MODEL: ______________________________ |

FILTERS

___ 1. Check/Replace Filters

___ 2. Check Filter Switch

___ 3. Wipe Section Clean

BLOWER SECTION

___ 1. Impellers Free of Debris & Spins Freely

___ 2. Check Belt Tension and Condition

___ 3. Check/Lube Bearings

___ 4. Check Pulleys and Motor Mounts

___ 5. Amp Draw ____ / ____ / ____

REHEAT

___ 1. Amp Draw ____ / ____ / ____

___ 2. Inspect elements for cleanliness

HUMIDIFIER

___ 1. Check for Clogs

___ 2. Check Humidifier Lamps/tank

___ 3. Check for Mineral Deposits

___ 4. Check Water

___ 5. Check Drain & Trap for Debris

___ 6. Check Amp Draw ____ / ____ / ____

REFRIGERATION CYCLE/SECTION

___ 1. Check Refrigerant Lines (rubbing)

___ 2. Suction Pressure 1.______ 2._______

___ 3. Discharge Pressure 1.______ 2.______

___ 4. Check Thermostatic Expansion Valve

___ 5. Check Superheat 1.______ 2.______

___ 6. Check Refrigerant Level (Site Glass)

ELECTRICAL PANEL

___ 1. Check Fuses

___ 2. Check Electrical Connections

___ 3. Check Operation Sequence

___ 4. Check Contactors for Pitting

COMPRESSOR

___ 1. Amp Draw 1. ____ / ____ / ____

___ 2. Amp Draw 2. ____ / ____ / ____

___ 3. Check For Leaks/Oil Level

___ 4. Vibration

___ 5. Noise

___ 6. Cap Tubes (Not Rubbing)

CONTROLS

___ 1. Check/Test Changeover Panel

___ 2. Check/Test Water Detection

___ 3. Check/Test Condensate Pump Operation

___ 4. Check/Verify Control Settings

AIR-COOLED CONDENSER/

DRYCOOLER

___ 1. Coil Clean

___ 2. Motor Mounts Tight

___ 3. Bearings in Good Condition

___ 4. Piping in Good Condition

___ 5. Ambient Settings ____ / ____ / ____

___ 6. Motor Amp Draws ____ / ____ / ____

___ 7. Check Electrical Connections

___ 8. Refrigerant/Glycol Level ______

___ 9. Cap. Tubes (Not Rubbing)

WATER/GLYCOL CONDENSER

___ 1. Copper Tube Clean

___ 2. Water Regulating Valve Functions

___ 3. Glycol Solution

___ 4. Check for Water/Glycol Leaks

GLYCOL PUMP

___ 1. Pump Rotation

___ 2. Glycol Leaks

___ 3. Pump Operation

___ 4. Amp Draw ____ / ____ / ____

___ 5. Pump Changeover (If Dual)

COMMENTS

_________________________________________________________________________

_________________________________________________________________________

57