Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

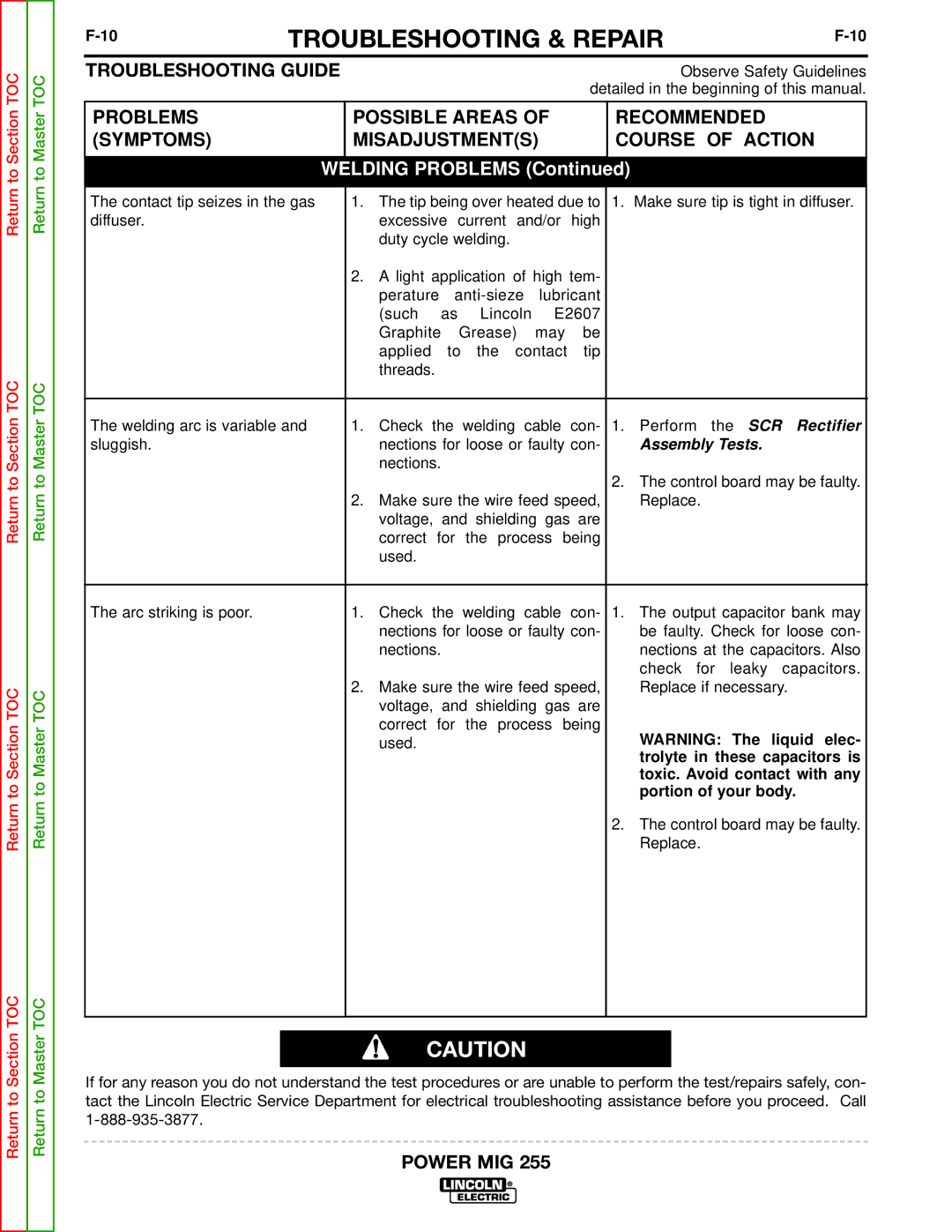

TROUBLESHOOTING & REPAIR | |||||||||

TROUBLESHOOTING GUIDE |

|

|

|

| Observe Safety Guidelines | ||||

|

|

|

|

|

|

| detailed in the beginning of this manual. | ||

|

|

|

|

|

|

| |||

PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED |

| |||

(SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| COURSE OF ACTION | ||||

|

|

|

|

|

| ||||

|

| WELDING PROBLEMS (Continued) |

|

| |||||

|

|

|

| ||||||

The contact tip seizes in the gas |

| 1. The tip being over heated due to | 1. Make sure tip is tight in diffuser. | ||||||

diffuser. |

|

| excessive | current and/or | high |

|

| ||

|

|

| duty cycle welding. |

|

|

|

| ||

|

|

| 2. A light application of high tem- |

|

| ||||

|

|

| perature |

|

| ||||

|

|

| (such | as | Lincoln E2607 |

|

| ||

|

|

| Graphite | Grease) | may | be |

|

| |

|

|

| applied to the contact tip |

|

| ||||

|

|

| threads. |

|

|

|

|

| |

|

|

|

|

|

|

|

| ||

The welding arc is variable and |

| 1. Check | the | welding | cable | con- | 1. Perform the SCR Rectifier | ||

sluggish. |

|

| nections for loose or faulty con- | Assembly Tests. |

| ||||

|

|

| nections. |

|

|

|

|

| |

|

|

|

|

|

|

|

| 2. The control board may be faulty. | |

|

|

| 2. Make sure the wire feed speed, | Replace. |

| ||||

|

|

| voltage, and shielding gas are |

|

| ||||

|

|

| correct for the process being |

|

| ||||

|

|

| used. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

The arc striking is poor. |

|

| 1. Check | the | welding | cable | con- | 1. The output capacitor bank may | |

|

|

| nections for loose or faulty con- | be faulty. Check for loose con- | |||||

|

|

| nections. |

|

|

| nections at the capacitors. Also | ||

|

|

|

|

|

|

|

| check for leaky | capacitors. |

|

|

| 2. Make sure the wire feed speed, | Replace if necessary. | |||||

|

|

| voltage, and shielding gas are |

|

| ||||

|

|

| correct for the process being | WARNING: The liquid elec- | |||||

|

|

| used. |

|

|

|

| ||

|

|

|

|

|

|

|

| trolyte in these capacitors is | |

|

|

|

|

|

|

|

| toxic. Avoid contact with any | |

|

|

|

|

|

|

|

| portion of your body. | |

|

|

|

|

|

|

|

| 2. The control board may be faulty. | |

|

|

|

|

|

|

|

| Replace. |

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call