MECHANICAL INSTALLATION — FUEL SYSTEM (DIESEL)

Diesel Fuel Supply

Consider the following when installing a diesel fuel supply system:

Fuel supply tank construction, location, installation, venting, piping, testing, and inspection must comply with all applicable codes. In addition, see NFPA Standards No. 30 and No. 37.

Fuel supply tanks must be adequately vented to prevent pressurization, have provisions for manually draining or pumping out water and sediment, and have at least a five percent expansion space to prevent fuel spillage when the fuel heats up and expands.

The fuel lift pump, day tank transfer pump, or float valve seat should be protected from fuel supply tank debris by a

The supply tank must hold enough fuel to run the genset for the prescribed number of hours (NFPA No. 110 Class designation) without refueling. Tank sizing calculation should be based on the hourly fuel consumption rates on the genset specification sheet.

For emergency power systems, codes might not permit the fuel supply to be used for any other purpose, or may specify a drawdown level for other equipment that guarantees the fuel supply for emergency power use.

The cetane rating of No. 2 heating oil is not high enough for dependable starting of diesel engines in extreme cold weather climates. Therefore, separate supply fuel tanks for emergency power and building heating systems may have to be provided.

Approved flexible fuel hose must be used for connections at the engine to prevent damage from genset movement and vibration.

Diesel fuel lines should be black iron pipe. Cast iron and aluminum pipe and fittings must NOT be used because they are porous and can leak.

Galvanized fuel lines, fittings, and tanks SHOULD NOT be used because the galvanized coating reacts with the sulfuric acid that forms when the sulfur in the fuel combines with tank condensation. Such a practice would result in debris that can clog fuel pumps and filters.

Although copper has been used for diesel fuel lines in the past, black iron pipe is preferred. Diesel fuel polymerizes (thickens) in copper tubing during long periods of standby. This can cause the fuel injectors to clog.

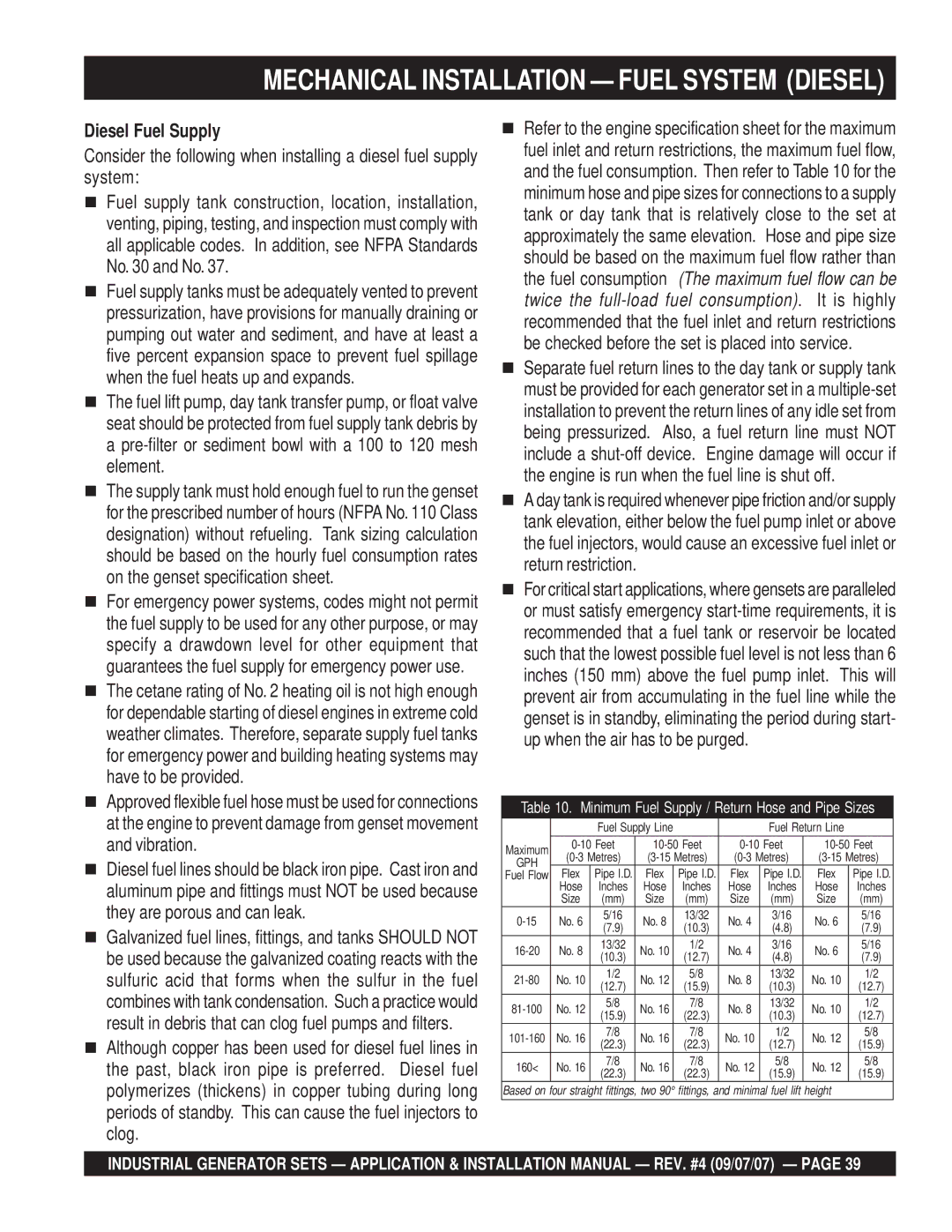

Refer to the engine specification sheet for the maximum fuel inlet and return restrictions, the maximum fuel flow, and the fuel consumption. Then refer to Table 10 for the minimum hose and pipe sizes for connections to a supply tank or day tank that is relatively close to the set at approximately the same elevation. Hose and pipe size should be based on the maximum fuel flow rather than the fuel consumption (The maximum fuel flow can be twice the

Separate fuel return lines to the day tank or supply tank must be provided for each generator set in a

A day tank is required whenever pipe friction and/or supply tank elevation, either below the fuel pump inlet or above the fuel injectors, would cause an excessive fuel inlet or return restriction.

For critical start applications, where gensets are paralleled or must satisfy emergency

Table 10. Minimum Fuel Supply / Return Hose and Pipe Sizes

|

| Fuel Supply Line |

|

| Fuel Return Line |

| |||

Maximum | |||||||||

GPH | |||||||||

Fuel Flow | Flex | Pipe I.D. | Flex | Pipe I.D. | Flex | Pipe I.D. | Flex | Pipe I.D. | |

| Hose | Inches | Hose | Inches | Hose | Inches | Hose | Inches | |

| Size | (mm) | Size | (mm) | Size | (mm) | Size | (mm) | |

No. 6 | 5/16 | No. 8 | 13/32 | No. 4 | 3/16 | No. 6 | 5/16 | ||

(7.9) | (10.3) | (4.8) | (7.9) | ||||||

|

|

|

|

| |||||

No. 8 | 13/32 | No. 10 | 1/2 | No. 4 | 3/16 | No. 6 | 5/16 | ||

(10.3) | (12.7) | (4.8) | (7.9) | ||||||

|

|

|

|

| |||||

No. 10 | 1/2 | No. 12 | 5/8 | No. 8 | 13/32 | No. 10 | 1/2 | ||

(12.7) | (15.9) | (10.3) | (12.7) | ||||||

|

|

|

|

| |||||

No. 12 | 5/8 | No. 16 | 7/8 | No. 8 | 13/32 | No. 10 | 1/2 | ||

(15.9) | (22.3) | (10.3) | (12.7) | ||||||

|

|

|

|

| |||||

No. 16 | 7/8 | No. 16 | 7/8 | No. 10 | 1/2 | No. 12 | 5/8 | ||

(22.3) | (22.3) | (12.7) | (15.9) | ||||||

|

|

|

|

| |||||

160< | No. 16 | 7/8 | No. 16 | 7/8 | No. 12 | 5/8 | No. 12 | 5/8 | |

(22.3) | (22.3) | (15.9) | (15.9) | ||||||

|

|

|

|

| |||||

Based on four straight fittings, two 90° fittings, and minimal fuel lift height

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 39