MECHANICAL INSTALLATION — HEAT EXCHANGER COOLING

Heat Exchanger

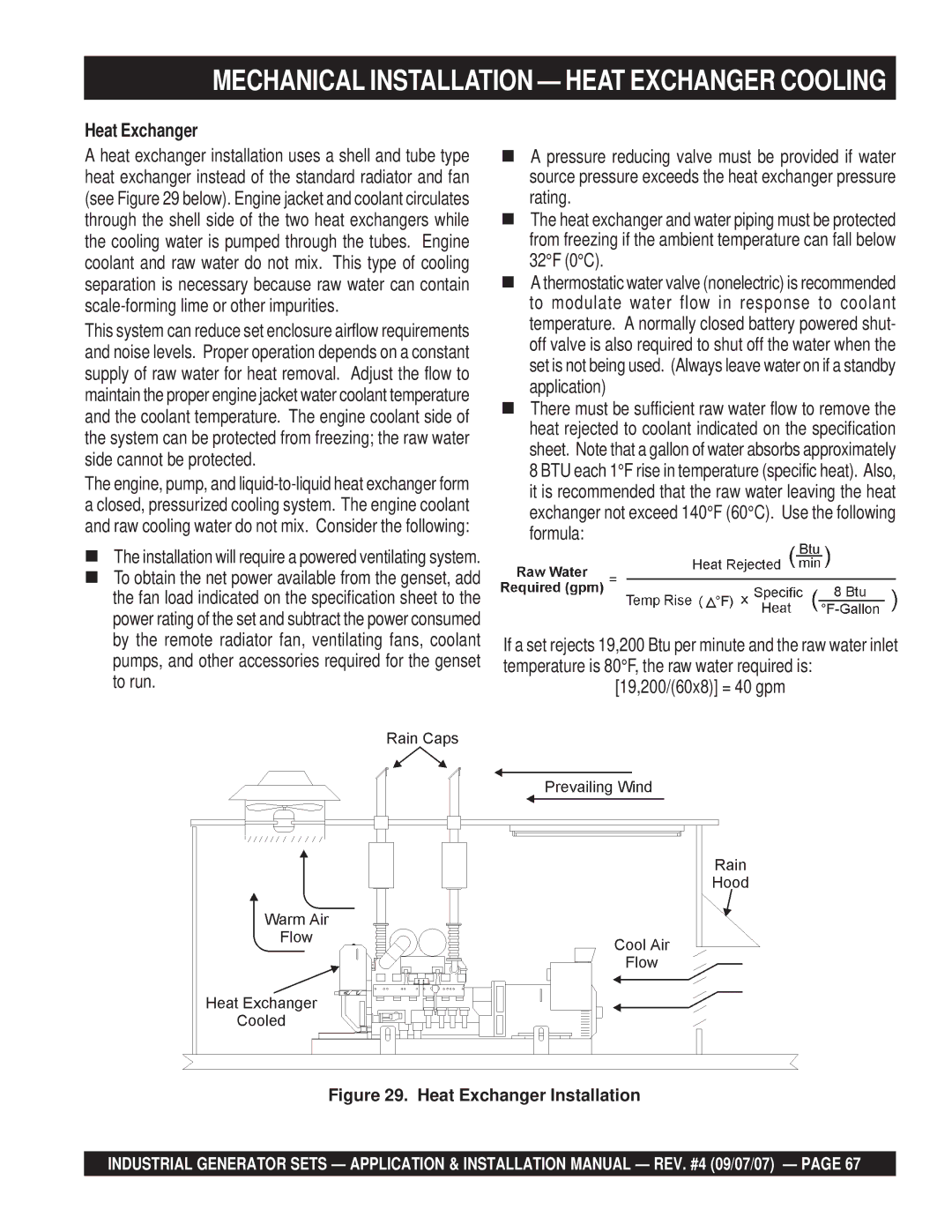

A heat exchanger installation uses a shell and tube type heat exchanger instead of the standard radiator and fan (see Figure 29 below). Engine jacket and coolant circulates through the shell side of the two heat exchangers while the cooling water is pumped through the tubes. Engine coolant and raw water do not mix. This type of cooling separation is necessary because raw water can contain

This system can reduce set enclosure airflow requirements and noise levels. Proper operation depends on a constant supply of raw water for heat removal. Adjust the flow to maintain the proper engine jacket water coolant temperature and the coolant temperature. The engine coolant side of the system can be protected from freezing; the raw water side cannot be protected.

The engine, pump, and

The installation will require a powered ventilating system.

To obtain the net power available from the genset, add the fan load indicated on the specification sheet to the power rating of the set and subtract the power consumed by the remote radiator fan, ventilating fans, coolant pumps, and other accessories required for the genset to run.

A pressure reducing valve must be provided if water source pressure exceeds the heat exchanger pressure rating.

The heat exchanger and water piping must be protected from freezing if the ambient temperature can fall below 32°F (0°C).

A thermostatic water valve (nonelectric) is recommended to modulate water flow in response to coolant temperature. A normally closed battery powered shut- off valve is also required to shut off the water when the set is not being used. (Always leave water on if a standby application)

There must be sufficient raw water flow to remove the heat rejected to coolant indicated on the specification sheet. Note that a gallon of water absorbs approximately 8 BTU each 1°F rise in temperature (specific heat). Also, it is recommended that the raw water leaving the heat exchanger not exceed 140°F (60°C). Use the following formula:

If a set rejects 19,200 Btu per minute and the raw water inlet temperature is 80°F, the raw water required is:

[19,200/(60x8)] = 40 gpm

Figure 29. Heat Exchanger Installation

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 67