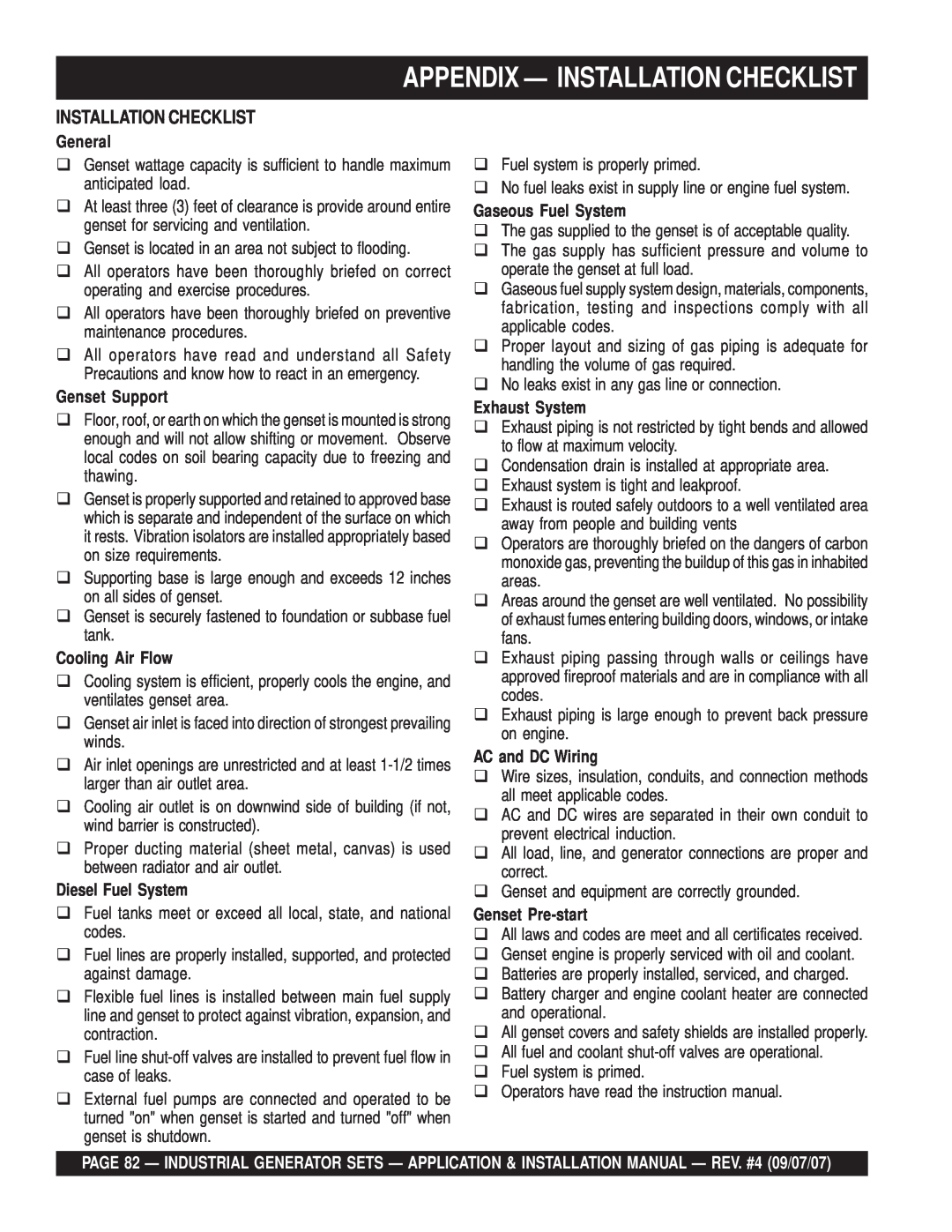

APPENDIX — INSTALLATION CHECKLIST

INSTALLATION CHECKLIST

General

Genset wattage capacity is sufficient to handle maximum anticipated load.

At least three (3) feet of clearance is provide around entire genset for servicing and ventilation.

Genset is located in an area not subject to flooding.

All operators have been thoroughly briefed on correct operating and exercise procedures.

All operators have been thoroughly briefed on preventive maintenance procedures.

All operators have read and understand all Safety Precautions and know how to react in an emergency.

Genset Support

Floor, roof, or earth on which the genset is mounted is strong enough and will not allow shifting or movement. Observe local codes on soil bearing capacity due to freezing and thawing.

Genset is properly supported and retained to approved base which is separate and independent of the surface on which it rests. Vibration isolators are installed appropriately based on size requirements.

Supporting base is large enough and exceeds 12 inches on all sides of genset.

Genset is securely fastened to foundation or subbase fuel tank.

Cooling Air Flow

Cooling system is efficient, properly cools the engine, and ventilates genset area.

Genset air inlet is faced into direction of strongest prevailing winds.

Air inlet openings are unrestricted and at least

Cooling air outlet is on downwind side of building (if not, wind barrier is constructed).

Proper ducting material (sheet metal, canvas) is used between radiator and air outlet.

Diesel Fuel System

Fuel tanks meet or exceed all local, state, and national codes.

Fuel lines are properly installed, supported, and protected against damage.

Flexible fuel lines is installed between main fuel supply line and genset to protect against vibration, expansion, and contraction.

Fuel line

External fuel pumps are connected and operated to be turned "on" when genset is started and turned "off" when genset is shutdown.

Fuel system is properly primed.

No fuel leaks exist in supply line or engine fuel system.

Gaseous Fuel System

The gas supplied to the genset is of acceptable quality.

The gas supply has sufficient pressure and volume to operate the genset at full load.

Gaseous fuel supply system design, materials, components, fabrication, testing and inspections comply with all applicable codes.

Proper layout and sizing of gas piping is adequate for handling the volume of gas required.

No leaks exist in any gas line or connection.

Exhaust System

Exhaust piping is not restricted by tight bends and allowed to flow at maximum velocity.

Condensation drain is installed at appropriate area.

Exhaust system is tight and leakproof.

Exhaust is routed safely outdoors to a well ventilated area away from people and building vents

Operators are thoroughly briefed on the dangers of carbon monoxide gas, preventing the buildup of this gas in inhabited areas.

Areas around the genset are well ventilated. No possibility of exhaust fumes entering building doors, windows, or intake fans.

Exhaust piping passing through walls or ceilings have approved fireproof materials and are in compliance with all codes.

Exhaust piping is large enough to prevent back pressure on engine.

AC and DC Wiring

Wire sizes, insulation, conduits, and connection methods all meet applicable codes.

AC and DC wires are separated in their own conduit to prevent electrical induction.

All load, line, and generator connections are proper and correct.

Genset and equipment are correctly grounded.

Genset Pre-start

All laws and codes are meet and all certificates received.

Genset engine is properly serviced with oil and coolant.

Batteries are properly installed, serviced, and charged.

Battery charger and engine coolant heater are connected and operational.

All genset covers and safety shields are installed properly.

All fuel and coolant

Fuel system is primed.

Operators have read the instruction manual.

PAGE 82 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)