Generator Set Sizing Calculations

The generator set must be sized to supply the maximum starting (power surge) demands and the

It is important to have the correct generator to meet the demands of the starting kVA (SkVA), starting kW (SkW), running kVA (RkVA) and running kW (RkW). A value for generator kW (GkW) is also obtained when nonlinear loads are included in the sizing calculation.

Once the starting and running loads have been determined, it is typical to add a margin factor of up to 25% for future expansion or to select a generator set of the next largest standard rating. A large connected load that does not run during usual power outages, such as a fire pump, can serve as part of a margin factor. For a fuel efficiency standpoint, the running load should stay within approximately 50 to 80% of the generator kW rating. To avoid "wet stacking", the running load should not be less than 30% of the generator set rating.

It may be necessary to oversize a generator set in applications where the voltage and frequency dip performance specifications are more stringent than usual, particularly when large motors are started

Static Uninterrupted Power Supplies (UPS)

Battery Charging Rectifiers (Telecommunications)

Variable Frequency Drives (VFD)

Medical Diagnostic Imaging Equipment

GENSET SIZING

The use of

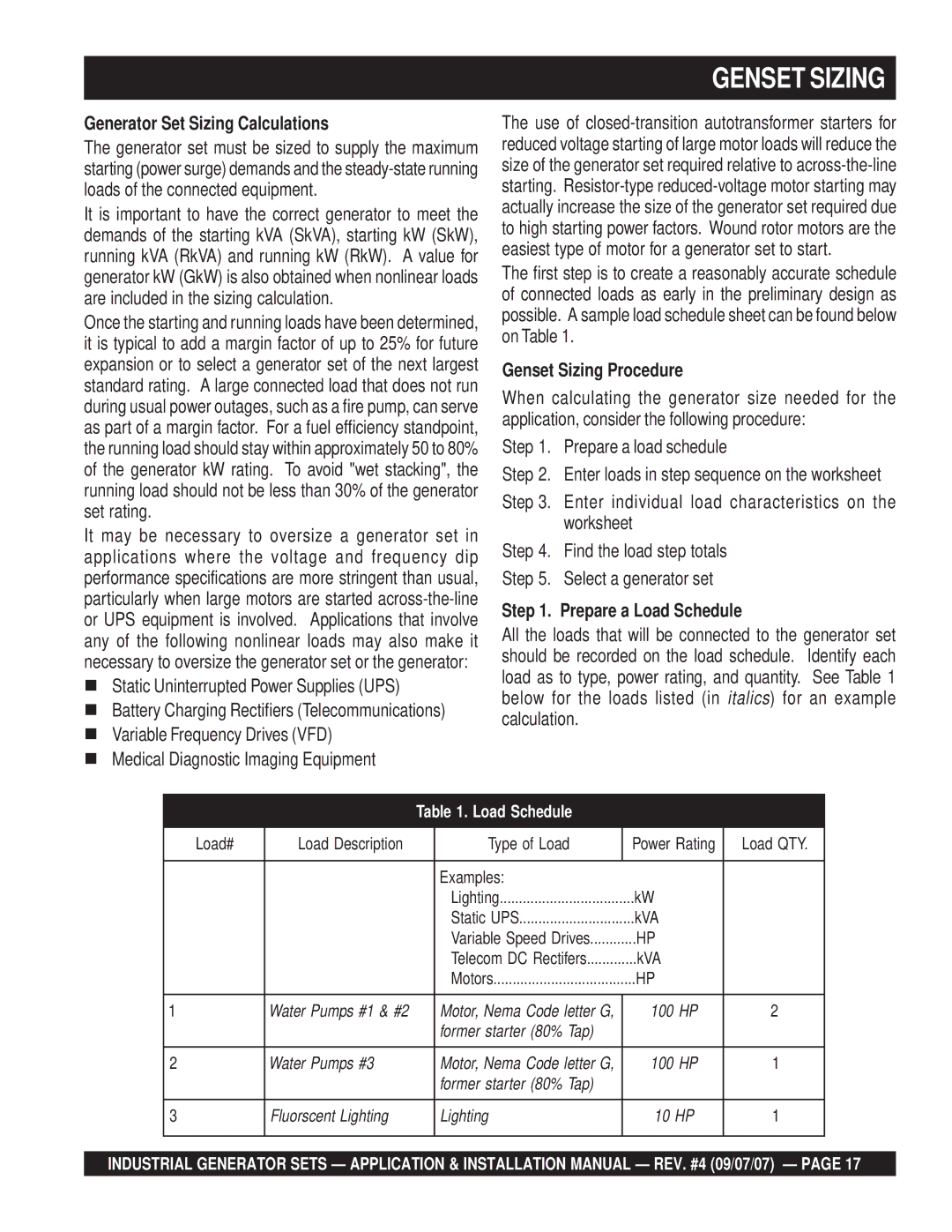

The first step is to create a reasonably accurate schedule of connected loads as early in the preliminary design as possible. A sample load schedule sheet can be found below on Table 1.

Genset Sizing Procedure

When calculating the generator size needed for the application, consider the following procedure:

Step 1. Prepare a load schedule

Step 2. Enter loads in step sequence on the worksheet

Step 3. Enter individual load characteristics on the worksheet

Step 4. Find the load step totals

Step 5. Select a generator set

Step 1. Prepare a Load Schedule

All the loads that will be connected to the generator set should be recorded on the load schedule. Identify each load as to type, power rating, and quantity. See Table 1 below for the loads listed (in italics) for an example calculation.

|

| Table 1. Load Schedule |

|

|

Load# | Load Description | Type of Load | Power Rating | Load QTY. |

|

| Examples: |

|

|

|

| Lighting | .kW |

|

|

| Static UPS | .kVA |

|

|

| Variable Speed Drives | .HP |

|

|

| Telecom DC Rectifers | .kVA |

|

|

| Motors | .HP |

|

1 | Water Pumps #1 & #2 | Motor, Nema Code letter G, | 100 HP | 2 |

|

| former starter (80% Tap) |

|

|

2 | Water Pumps #3 | Motor, Nema Code letter G, | 100 HP | 1 |

|

| former starter (80% Tap) |

|

|

3 | Fluorscent Lighting | Lighting | 10 HP | 1 |

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 17