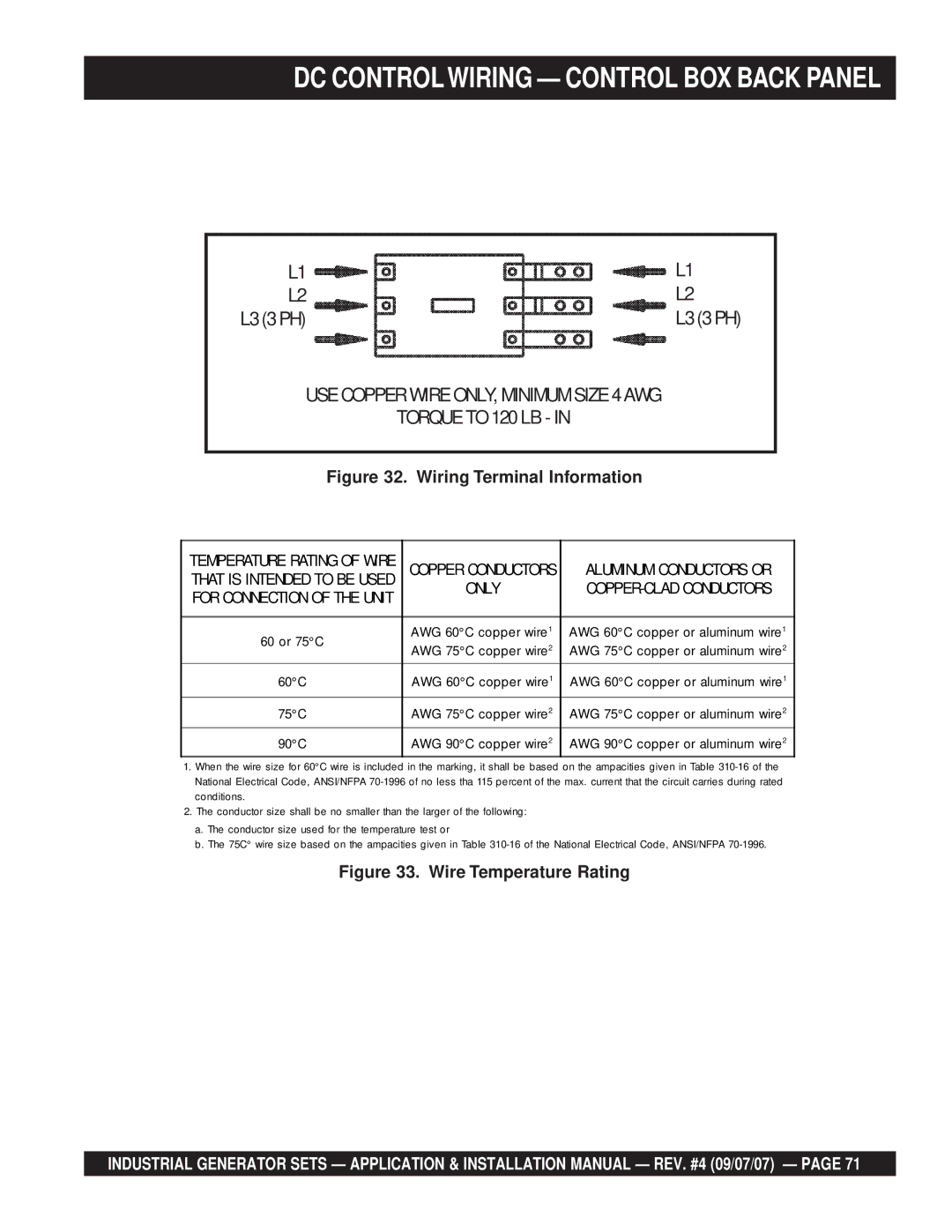

DC CONTROLWIRING — CONTROL BOX BACK PANEL

| L1 |

|

|

| L1 |

|

| L2 |

|

|

| L2 |

|

| L3 (3 PH) |

|

|

| L3 (3 PH) |

|

| USE COPPER WIRE ONLY, MINIMUM SIZE 4 AWG |

| ||||

|

| TORQUE TO 120 LB - IN |

|

| ||

|

|

|

|

| ||

| Figure 32. Wiring Terminal Information | |||||

|

|

|

|

| ||

TEMPERATURE RATING OF WIRE |

| COPPER CONDUCTORS |

| ALUMINUM CONDUCTORS OR | ||

THAT IS INTENDED TO BE USED |

| ONLY |

| |||

FOR CONNECTION OF THE UNIT |

|

| ||||

|

|

|

|

| ||

|

|

|

|

|

| |

| 60 or 75°C |

| AWG 60°C copper wire1 |

| AWG 60°C copper or aluminum wire1 | |

|

| AWG 75°C copper wire2 |

| AWG 75°C copper or aluminum wire2 | ||

|

|

|

| |||

| 60°C |

| AWG 60°C copper wire1 |

| AWG 60°C copper or aluminum wire1 | |

|

|

|

|

|

| |

| 75°C |

| AWG 75°C copper wire2 |

| AWG 75°C copper or aluminum wire2 | |

|

|

|

|

|

| |

| 90°C |

| AWG 90°C copper wire2 |

| AWG 90°C copper or aluminum wire2 | |

|

|

|

|

|

|

|

1.When the wire size for 60°C wire is included in the marking, it shall be based on the ampacities given in Table

2.The conductor size shall be no smaller than the larger of the following:

a.The conductor size used for the temperature test or

b.The 75C° wire size based on the ampacities given in Table

Figure 33. Wire Temperature Rating

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 71