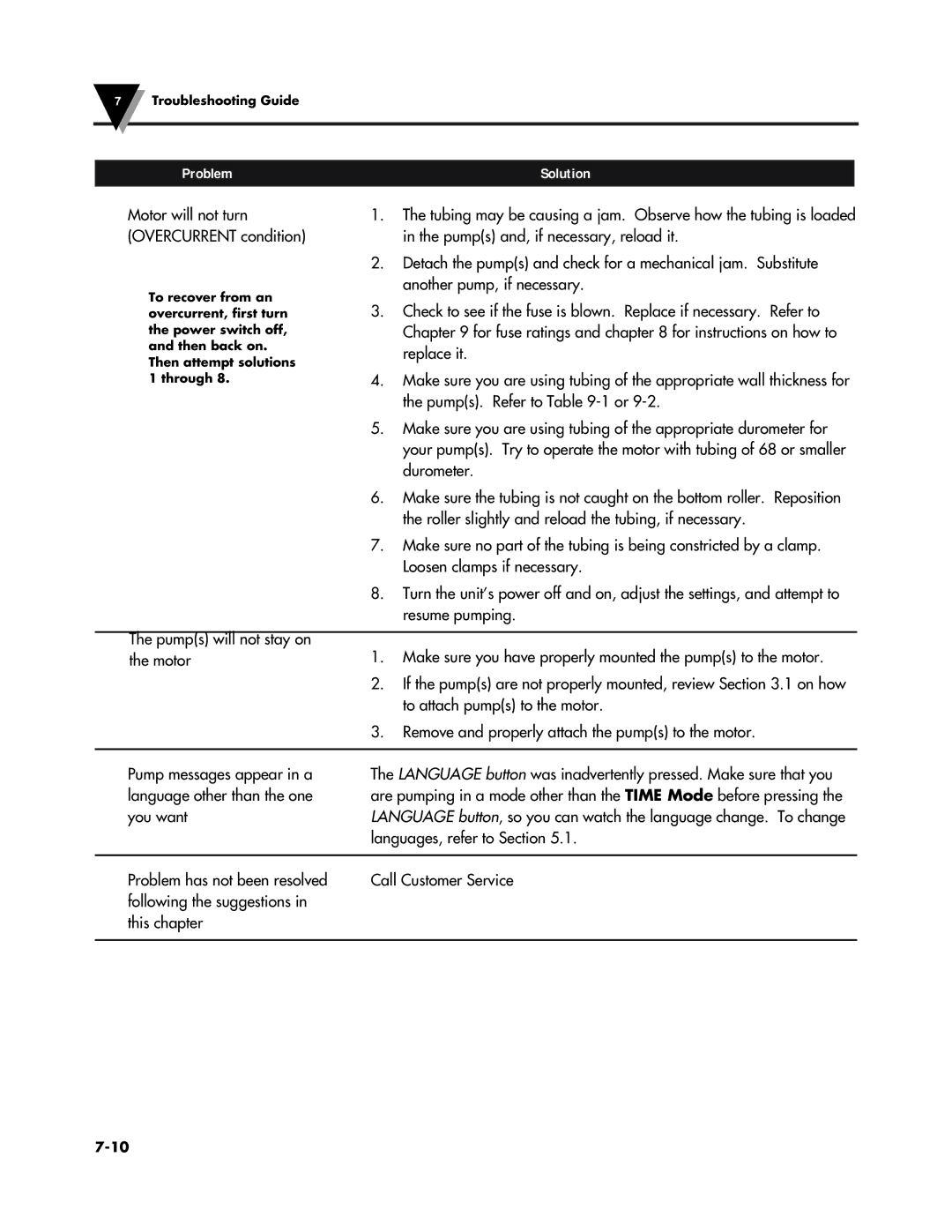

7Troubleshooting Guide

Problem |

| Solution |

| |

Motor will not turn | 1. | The tubing may be causing a jam. Observe how the tubing is loaded | ||

(OVERCURRENT condition) |

| in the pump(s) and, if necessary, reload it. | ||

| 2. | Detach the pump(s) and check for a mechanical jam. Substitute | ||

To recover from an |

| another pump, if necessary. | ||

3. | Check to see if the fuse is blown. Replace if necessary. Refer to | |||

overcurrent, first turn | ||||

the power switch off, |

| Chapter 9 for fuse ratings and chapter 8 for instructions on how to | ||

and then back on. |

| replace it. | ||

Then attempt solutions |

| |||

|

|

| ||

1 through 8. | 4. | Make sure you are using tubing of the appropriate wall thickness for | ||

|

| the pump(s). Refer to Table | ||

| 5. | Make sure you are using tubing of the appropriate durometer for | ||

|

| your pump(s). Try to operate the motor with tubing of 68 or smaller | ||

|

| durometer. | ||

| 6. | Make sure the tubing is not caught on the bottom roller. Reposition | ||

|

| the roller slightly and reload the tubing, if necessary. | ||

| 7. | Make sure no part of the tubing is being constricted by a clamp. | ||

|

| Loosen clamps if necessary. | ||

| 8. | Turn the unit’s power off and on, adjust the settings, and attempt to | ||

|

| resume pumping. | ||

|

|

|

| |

The pump(s) will not stay on | 1. | Make sure you have properly mounted the pump(s) to the motor. | ||

the motor | ||||

| 2. | If the pump(s) are not properly mounted, review Section 3.1 on how | ||

|

| to attach pump(s) to the motor. | ||

| 3. | Remove and properly attach the pump(s) to the motor. | ||

|

|

|

| |

Pump messages appear in a language other than the one you want

The LANGUAGE button was inadvertently pressed. Make sure that you are pumping in a mode other than the TIME Mode before pressing the LANGUAGE button, so you can watch the language change. To change languages, refer to Section 5.1.

Problem has not been resolved | Call Customer Service |

following the suggestions in |

|

this chapter |

|

|

|