Operating the Pump Motor in the RUNNING Display Mode | 6 |

|

|

6.5 Preventing Tubing from Moving During Pump Operation

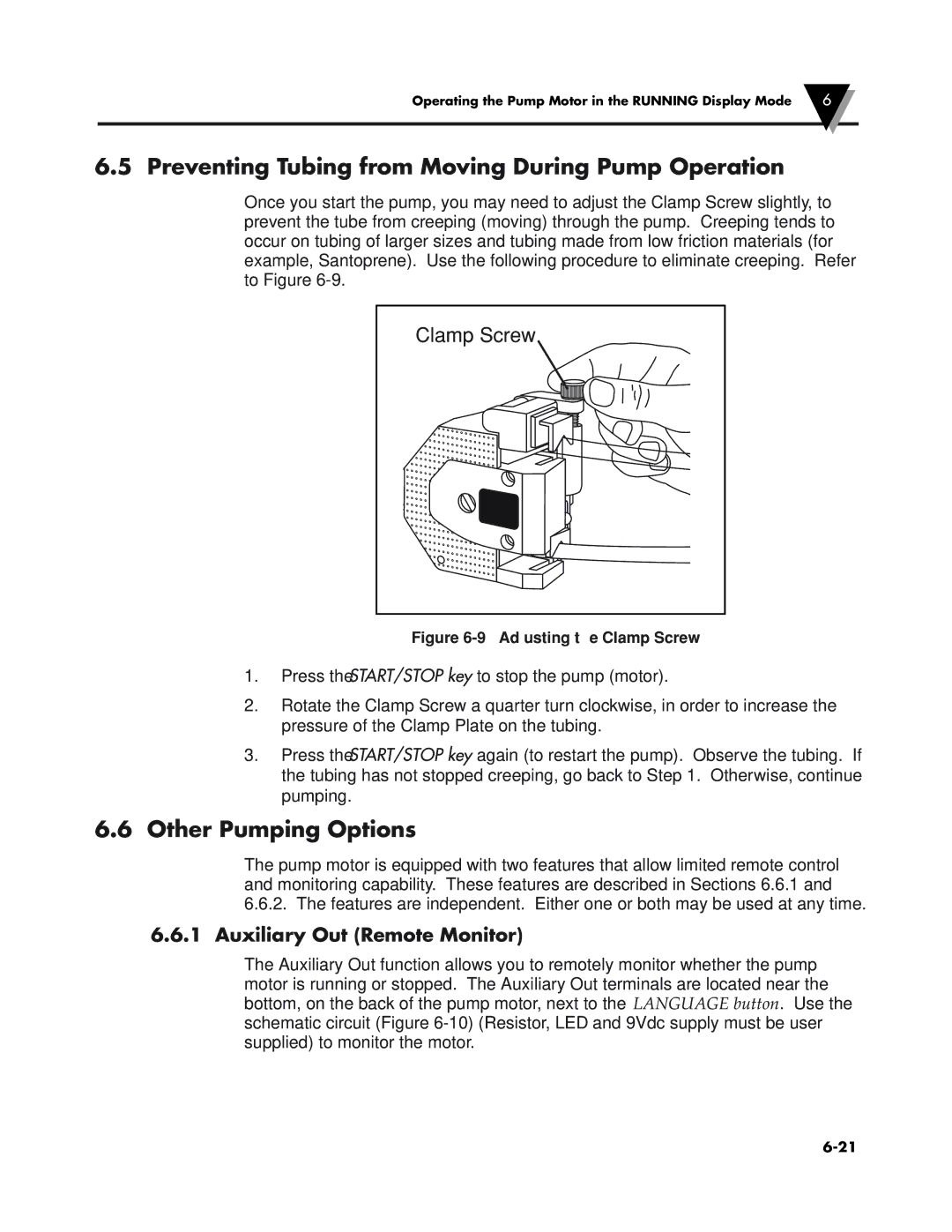

Once you start the pump, you may need to adjust the Clamp Screw slightly, to prevent the tube from creeping (moving) through the pump. Creeping tends to occur on tubing of larger sizes and tubing made from low friction materials (for example, Santoprene). Use the following procedure to eliminate creeping. Refer to Figure

Clamp Screw

Figure 6-9. Adjusting the Clamp Screw

1.Press the START/STOP key to stop the pump (motor).

2.Rotate the Clamp Screw a quarter turn clockwise, in order to increase the pressure of the Clamp Plate on the tubing.

3.Press the START/STOP key again (to restart the pump). Observe the tubing. If the tubing has not stopped creeping, go back to Step 1. Otherwise, continue pumping.

6.6Other Pumping Options

The pump motor is equipped with two features that allow limited remote control and monitoring capability. These features are described in Sections 6.6.1 and

6.6.2.The features are independent. Either one or both may be used at any time.

6.6.1Auxiliary Out (Remote Monitor)

The Auxiliary Out function allows you to remotely monitor whether the pump motor is running or stopped. The Auxiliary Out terminals are located near the bottom, on the back of the pump motor, next to the LANGUAGE button. Use the schematic circuit (Figure