18X | 107T5 |

Go to cover page

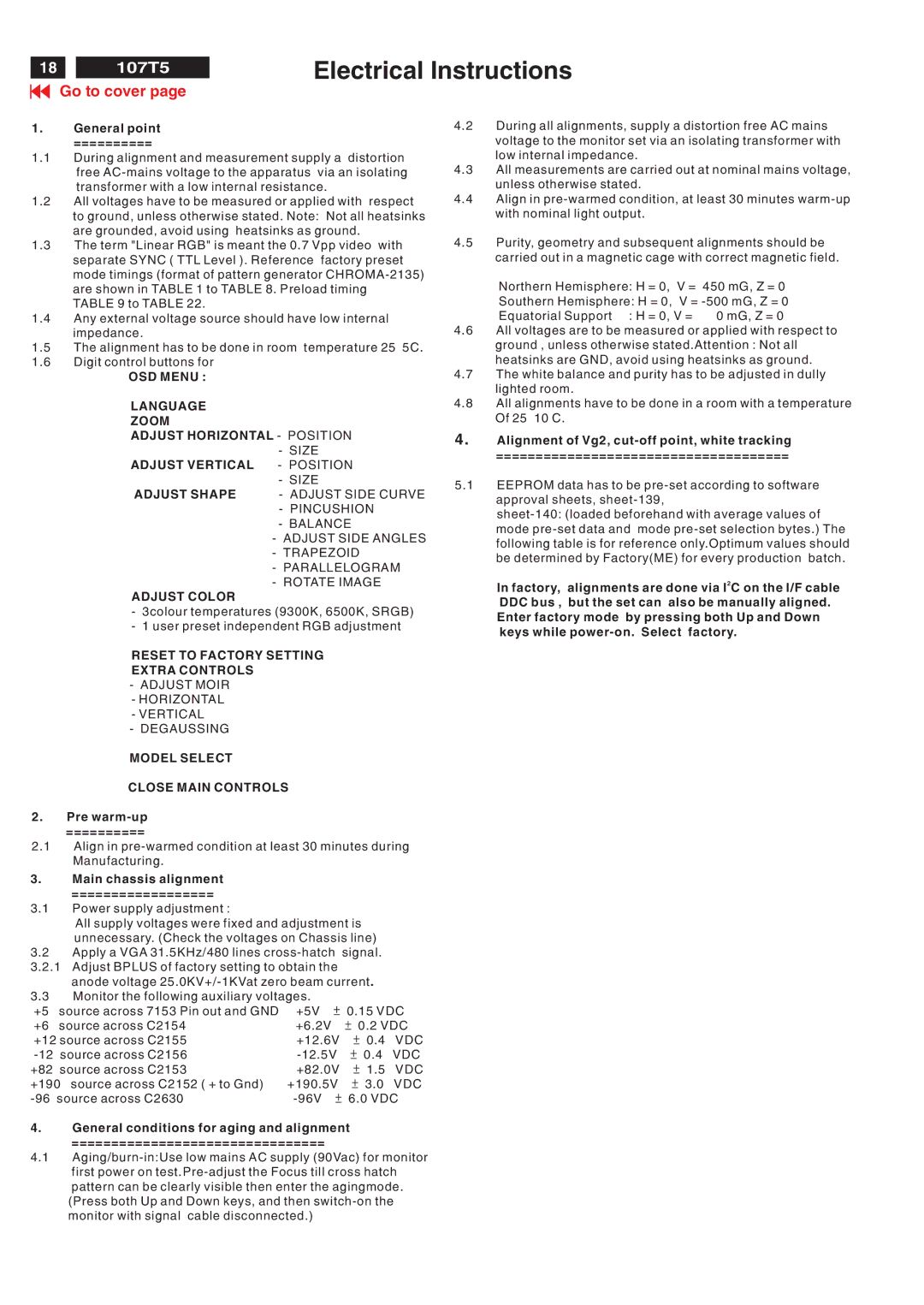

Electrical Instructions

1.General point

==========

1.1During alignment and measurement supply a distortion free

1.2All voltages have to be measured or applied with respect to ground, unless otherwise stated. Note: Not all heatsinks are grounded, avoid using heatsinks as ground.

1.3The term "Linear RGB" is meant the 0.7 Vpp video with separate SYNC ( TTL Level ). Reference factory preset mode timings (format of pattern generator

1.4Any external voltage source should have low internal impedance.

1.5The alignment has to be done in room temperature 25 5C.

1.6Digit control buttons for

OSD MENU :

LANGUAGE

ZOOM

ADJUST HORIZONTAL - POSITION

| - SIZE |

ADJUST VERTICAL | - POSITION |

| - SIZE |

ADJUST SHAPE | - ADJUST SIDE CURVE |

| - PINCUSHION |

| - BALANCE |

| - ADJUST SIDE ANGLES |

| - TRAPEZOID |

| - PARALLELOGRAM |

| - ROTATE IMAGE |

ADJUST COLOR |

|

-3colour temperatures (9300K, 6500K, SRGB)

-1 user preset independent RGB adjustment

RESET TO FACTORY SETTING

EXTRA CONTROLS

-ADJUST MOIR

-HORIZONTAL

-VERTICAL

-DEGAUSSING

MODEL SELECT

CLOSE MAIN CONTROLS

2.Pre warm-up

==========

2.1Align in

3.Main chassis alignment

==================

3.1Power supply adjustment :

All supply voltages were fixed and adjustment is unnecessary. (Check the voltages on Chassis line)

3.2Apply a VGA 31.5KHz/480 lines

3.2.1 Adjust BPLUS of factory setting to obtain the anode voltage

3.3Monitor the following auxiliary voltages.

+5 source across 7153 Pin out and GND | +5V | 0.15 VDC | ||

+6 | source across C2154 | +6.2V | 0.2 VDC | |

+12 source across C2155 | +12.6V | 0.4 | VDC | |

source across C2156 | 0.4 | VDC | ||

+82 | source across C2153 | +82.0V | 1.5 | VDC |

+190 source across C2152 ( + to Gnd) | +190.5V | 3.0 | VDC | |

6.0 VDC | ||||

4.General conditions for aging and alignment

================================

4.1

(Press both Up and Down keys, and then

4.2During all alignments, supply a distortion free AC mains voltage to the monitor set via an isolating transformer with low internal impedance.

4.3All measurements are carried out at nominal mains voltage, unless otherwise stated.

4.4Align in

4.5Purity, geometry and subsequent alignments should be carried out in a magnetic cage with correct magnetic field.

Northern Hemisphere: H = 0, V = 450 mG, Z = 0

Southern Hemisphere: H = 0, V =

Equatorial Support : H = 0, V = 0 mG, Z = 0

4.6All voltages are to be measured or applied with respect to ground , unless otherwise stated.Attention : Not all heatsinks are GND, avoid using heatsinks as ground.

4.7The white balance and purity has to be adjusted in dully lighted room.

4.8All alignments have to be done in a room with a temperature Of 25 10 C.

4.Alignment of Vg2,

=====================================

5.1EEPROM data has to be

In factory, alignments are done via I2C on the I/F cable DDC bus , but the set can also be manually aligned. Enter factory mode by pressing both Up and Down keys while