Basic Lathe Operations (continued)

6.Use the faceplate

IMPORTANT: Do not use smaller size screws or sheet rock screws as they are too brittle and could break, causing the workpiece to come loose and possibly causing injury.

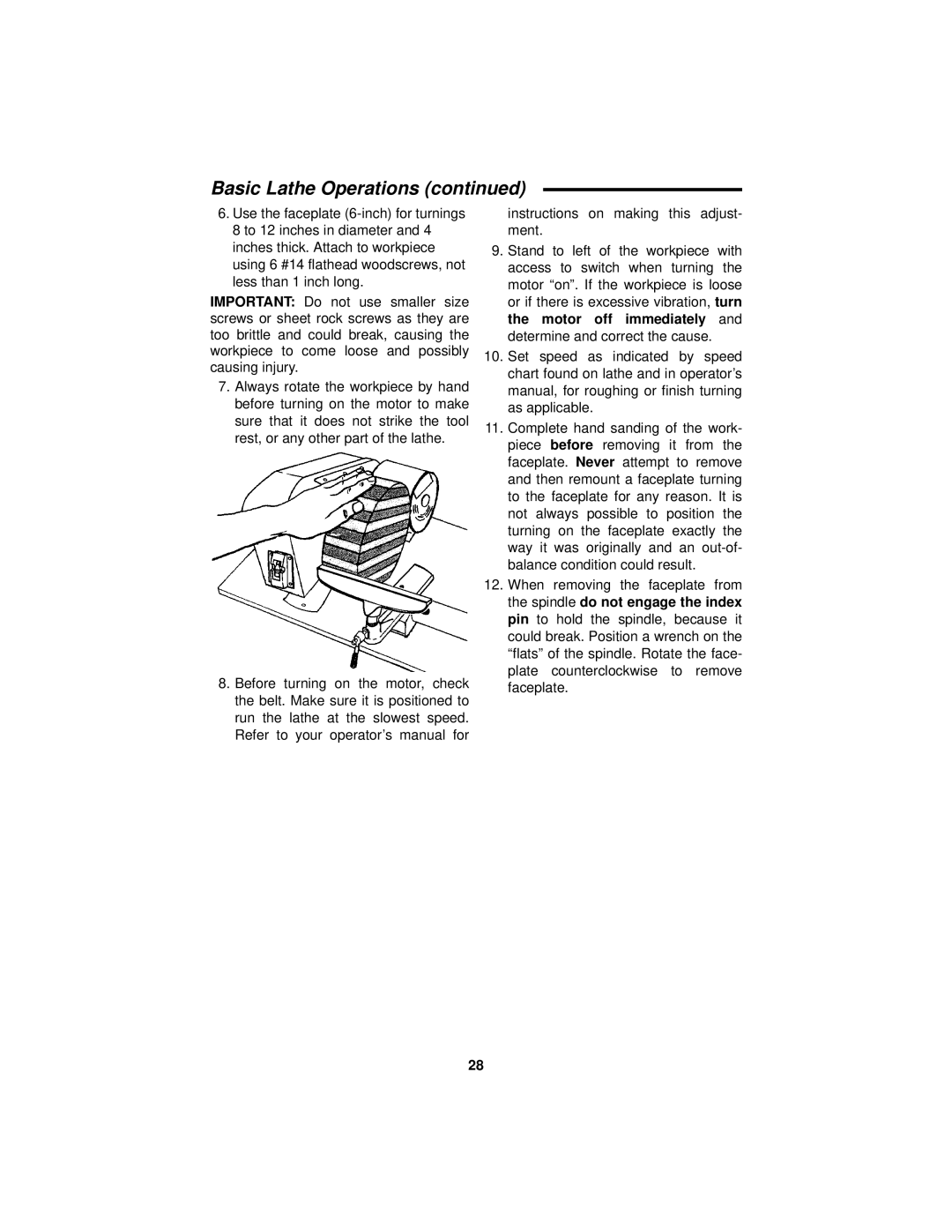

7.Always rotate the workpiece by hand before turning on the motor to make sure that it does not strike the tool rest, or any other part of the lathe.

8.Before turning on the motor, check the belt. Make sure it is positioned to run the lathe at the slowest speed. Refer to your operator’s manual for

instructions on making this adjust- ment.

9.Stand to left of the workpiece with access to switch when turning the motor “on”. If the workpiece is loose or if there is excessive vibration, turn the motor off immediately and determine and correct the cause.

10.Set speed as indicated by speed chart found on lathe and in operator’s manual, for roughing or finish turning as applicable.

11.Complete hand sanding of the work- piece before removing it from the faceplate. Never attempt to remove and then remount a faceplate turning to the faceplate for any reason. It is not always possible to position the turning on the faceplate exactly the way it was originally and an

12.When removing the faceplate from the spindle do not engage the index pin to hold the spindle, because it could break. Position a wrench on the “flats” of the spindle. Rotate the face- plate counterclockwise to remove faceplate.

28