Deep Recesses

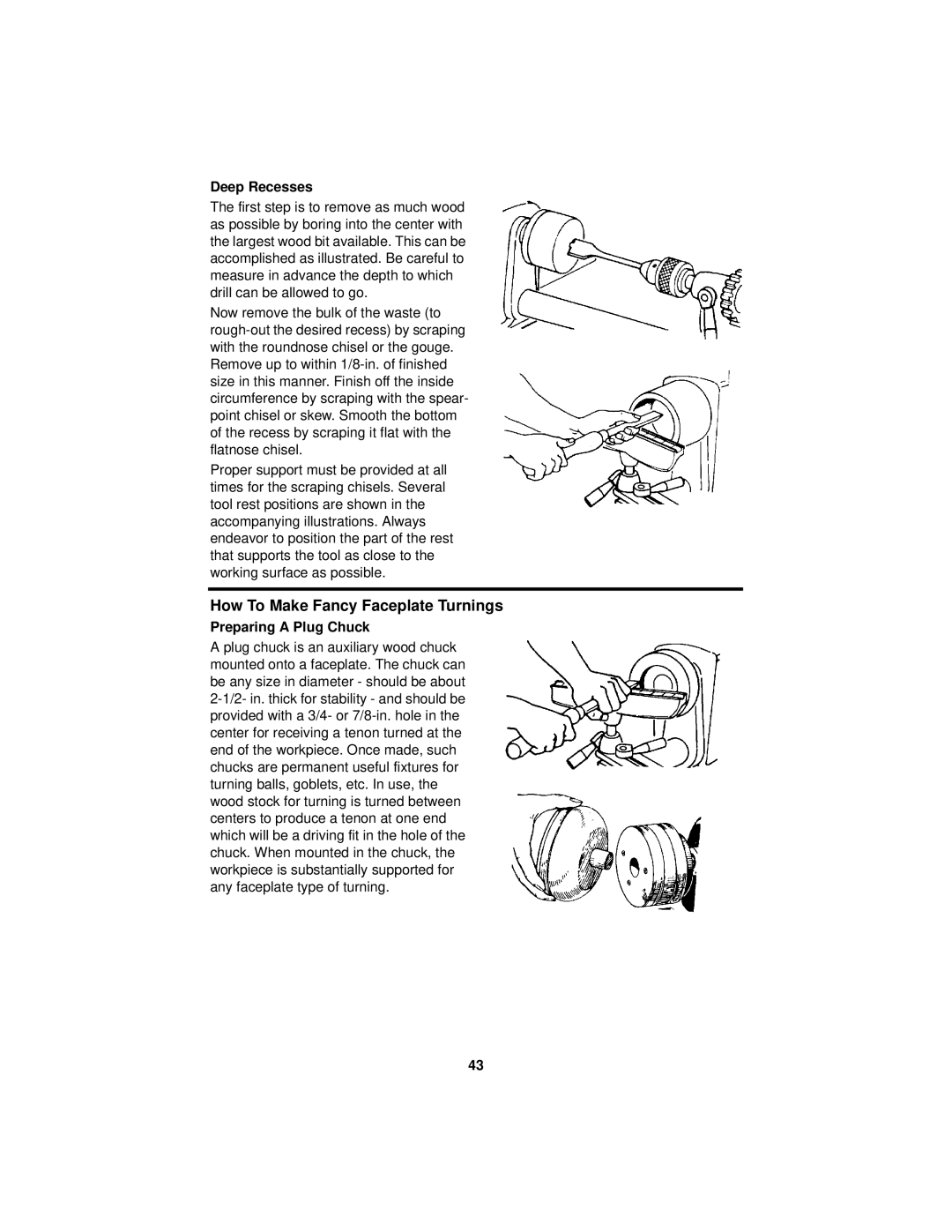

The first step is to remove as much wood as possible by boring into the center with the largest wood bit available. This can be accomplished as illustrated. Be careful to measure in advance the depth to which drill can be allowed to go.

Now remove the bulk of the waste (to rough-out the desired recess) by scraping with the roundnose chisel or the gouge. Remove up to within 1/8-in. of finished size in this manner. Finish off the inside circumference by scraping with the spear- point chisel or skew. Smooth the bottom of the recess by scraping it flat with the flatnose chisel.

Proper support must be provided at all times for the scraping chisels. Several tool rest positions are shown in the accompanying illustrations. Always endeavor to position the part of the rest that supports the tool as close to the working surface as possible.

How To Make Fancy Faceplate Turnings

Preparing A Plug Chuck

A plug chuck is an auxiliary wood chuck mounted onto a faceplate. The chuck can be any size in diameter - should be about 2-1/2- in. thick for stability - and should be provided with a 3/4- or 7/8-in. hole in the center for receiving a tenon turned at the end of the workpiece. Once made, such chucks are permanent useful fixtures for turning balls, goblets, etc. In use, the wood stock for turning is turned between centers to produce a tenon at one end which will be a driving fit in the hole of the chuck. When mounted in the chuck, the workpiece is substantially supported for any faceplate type of turning.