How To Use Your RIDGID Wood Lathe

Woodworking Chisels and How to Use Them

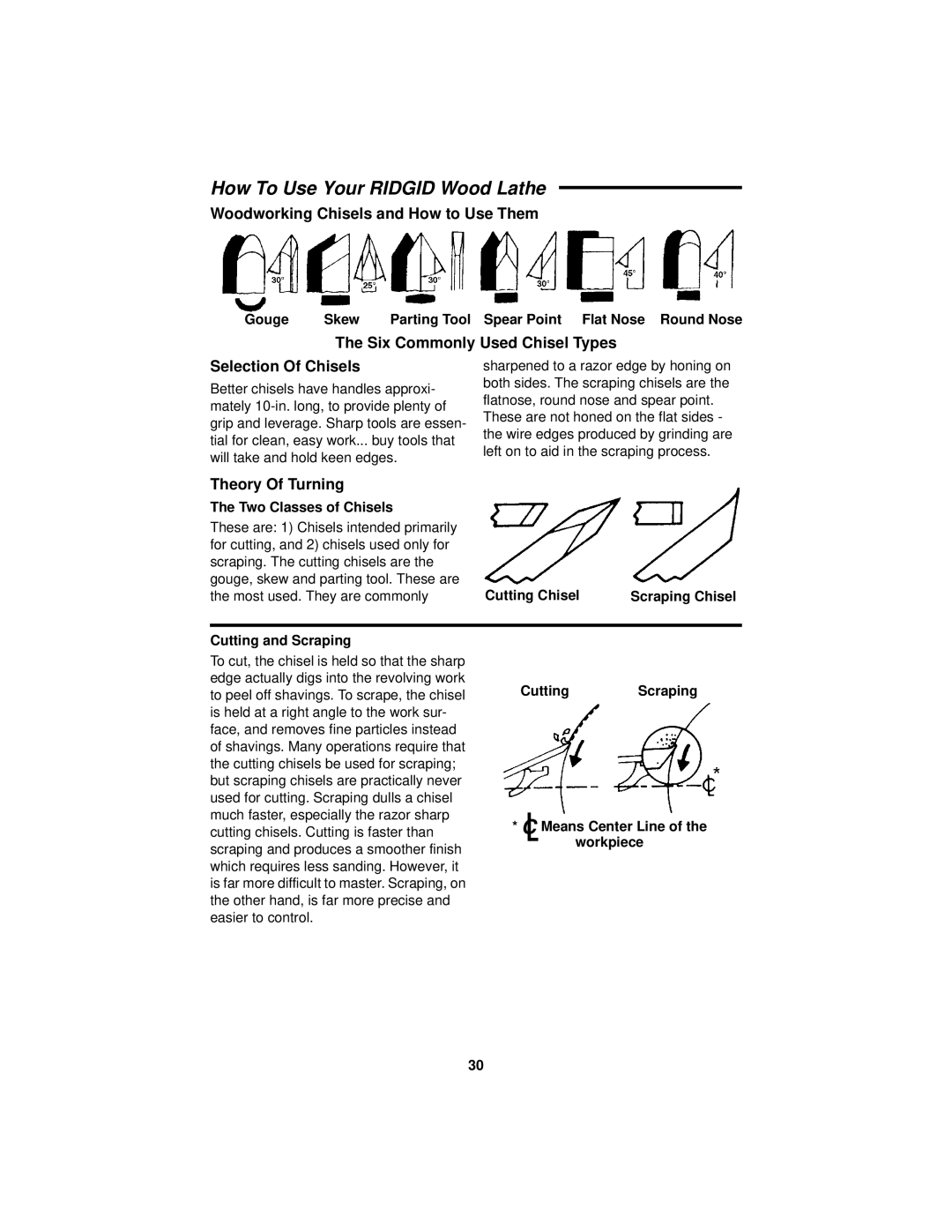

Gouge | Skew | Parting Tool Spear Point Flat Nose Round Nose |

The Six Commonly Used Chisel Types

Selection Of Chisels

Better chisels have handles approxi- mately

sharpened to a razor edge by honing on both sides. The scraping chisels are the flatnose, round nose and spear point.

These are not honed on the flat sides - the wire edges produced by grinding are left on to aid in the scraping process.

Theory Of Turning

The Two Classes of Chisels |

|

|

These are: 1) Chisels intended primarily |

|

|

for cutting, and 2) chisels used only for |

|

|

scraping. The cutting chisels are the |

|

|

gouge, skew and parting tool. These are |

|

|

the most used. They are commonly | Cutting Chisel | Scraping Chisel |

Cutting and Scraping

To cut, the chisel is held so that the sharp edge actually digs into the revolving work to peel off shavings. To scrape, the chisel is held at a right angle to the work sur- face, and removes fine particles instead of shavings. Many operations require that the cutting chisels be used for scraping; but scraping chisels are practically never used for cutting. Scraping dulls a chisel much faster, especially the razor sharp cutting chisels. Cutting is faster than scraping and produces a smoother finish which requires less sanding. However, it is far more difficult to master. Scraping, on the other hand, is far more precise and easier to control.

CuttingScraping

*C Means Center Line of the

![]() workpiece

workpiece

30