How to Use Your RIDGID Wood Lathe (continued)

Making Standard Cuts

The | has been formed, step lathe up to the next |

| ||

Reducing a square or | faster speed. Further reductions in size |

| ||

piece down to a cylinder of approximate | can now be carried out by cutting as |

| ||

size for finish turning is called “Roughing- | deeply as desired at any spot along the |

| ||

off”. Faceplate turning and large diameter | work. At this stage, long cuts, from the |

| ||

spindles should first be partly reduced by | center off either end, can also be taken. |

| ||

sawing but small spindles are easily turned |

| |||

down entirely with the large | the cylinder is approximately |

| ||

Start the first cut about | than the desired finish size. Roundness |

| ||

can be tested by laying the gouge on top |

| |||

end - then run it toward the tailstock and |

| |||

of the work - it will not ride up and down |

| |||

off the end of the workpiece. Next, start |

| |||

when cylinder is perfectly round. |

| |||

another cut |

| |||

|

|

|

| |

and run it, also, toward tailstock, to merge |

|

|

|

|

with first cut. Continue in this manner until |

|

|

|

|

2- to |

|

|

|

|

reverse the direction of tool travel and |

|

|

|

|

work one or two cuts in succession |

|

|

|

|

toward the headstock, and off this end of |

|

|

|

|

the workpiece. NOTE: Never start a cut |

|

|

|

|

directly at the end |

|

|

|

|

the end, it will damage the workpiece. |

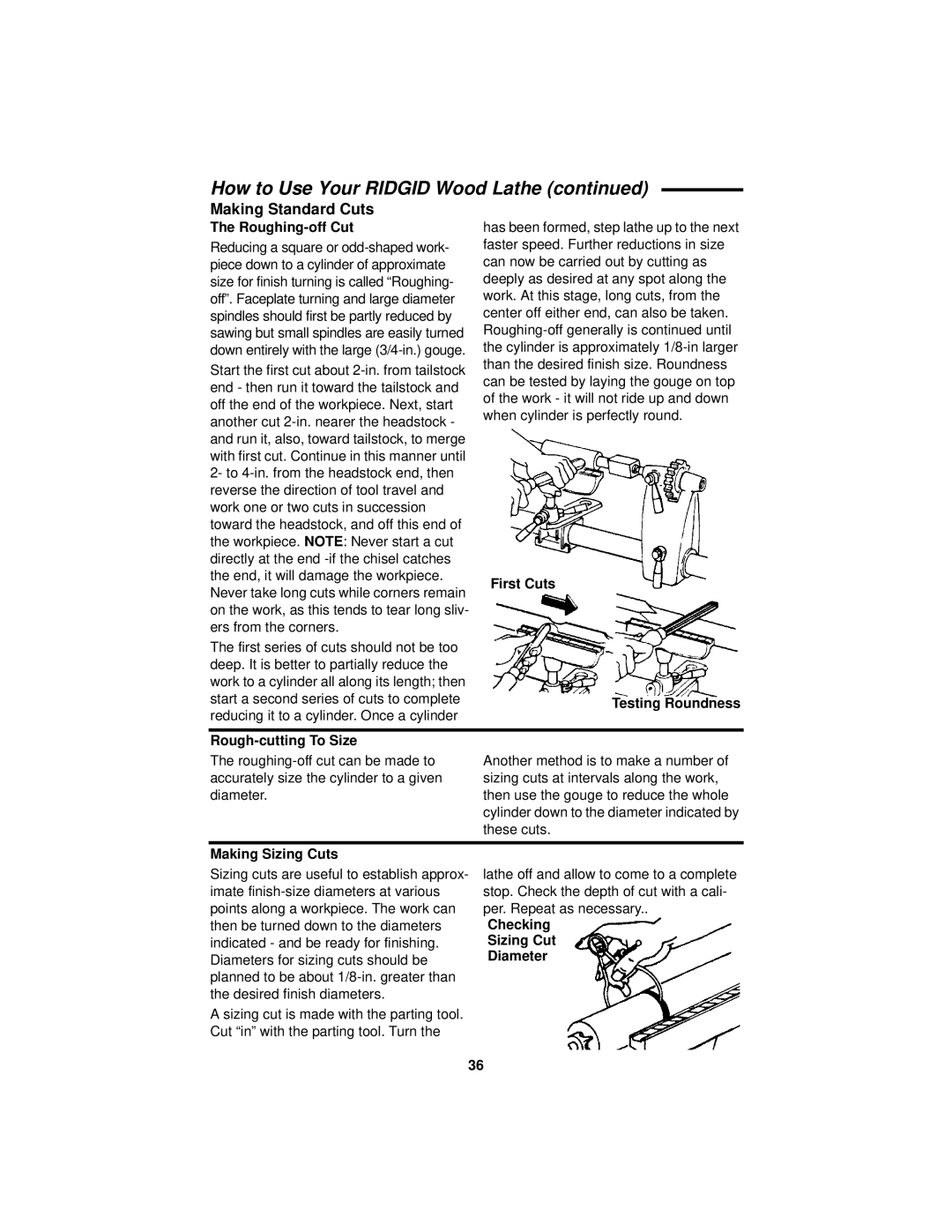

| First Cuts |

| |

Never take long cuts while corners remain |

|

| ||

|

|

|

| |

on the work, as this tends to tear long sliv- |

|

|

|

|

ers from the corners. |

|

|

|

|

The first series of cuts should not be too |

|

|

|

|

deep. It is better to partially reduce the |

|

|

|

|

work to a cylinder all along its length; then |

|

|

|

|

start a second series of cuts to complete |

|

|

|

|

|

|

|

| |

| Testing Roundness |

| ||

reducing it to a cylinder. Once a cylinder |

|

| ||

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

The

Another method is to make a number of sizing cuts at intervals along the work, then use the gouge to reduce the whole cylinder down to the diameter indicated by these cuts.

Making Sizing Cuts

Sizing cuts are useful to establish approx- imate

A sizing cut is made with the parting tool. Cut “in” with the parting tool. Turn the

lathe off and allow to come to a complete stop. Check the depth of cut with a cali- per. Repeat as necessary..

Checking

Sizing Cut

Diameter

36