Turning A Ring |

|

|

|

| |

One method of turning a ring requires a |

|

|

|

| |

spindle chuck. The work stock is first |

|

|

|

| |

mounted to a backing block held by the |

|

|

|

| |

large faceplate, and is turned to shape on |

|

|

|

| |

the outer side. The inside diameter of the |

|

|

|

| |

ring is also shaped, all the way through to |

|

|

|

| |

the backing block. The work is then |

|

|

|

| |

removed from the backing block. A spin- |

|

|

|

| |

dle chuck is now prepared so that it will be |

|

|

|

| |

a tight press fit inside the ring, and the |

|

|

|

| |

ring is reversed and mounted on this |

|

|

|

| |

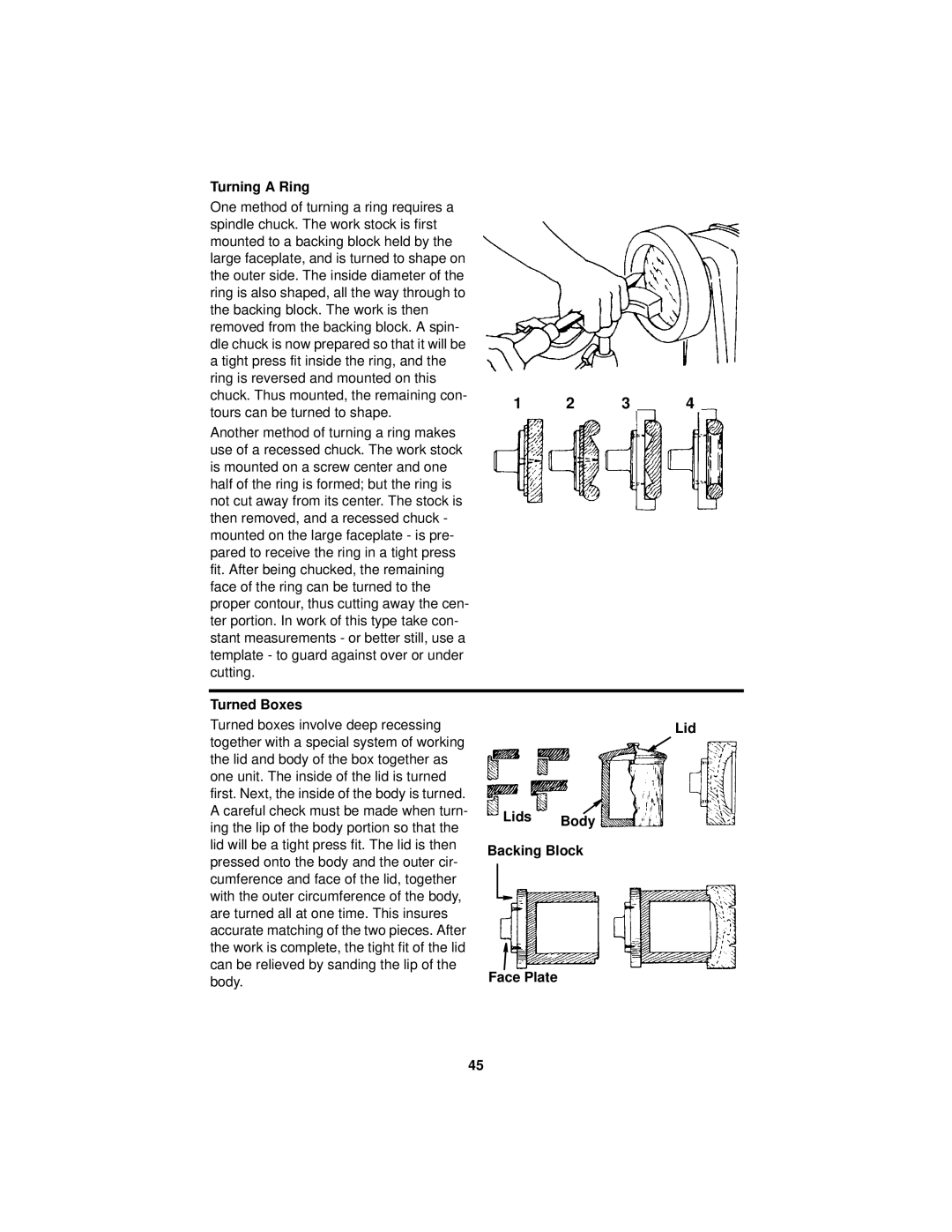

chuck. Thus mounted, the remaining con- | 1 | 2 | 3 | 4 | |

tours can be turned to shape. | |||||

|

|

|

|

Another method of turning a ring makes use of a recessed chuck. The work stock is mounted on a screw center and one half of the ring is formed; but the ring is not cut away from its center. The stock is then removed, and a recessed chuck - mounted on the large faceplate - is pre- pared to receive the ring in a tight press fit. After being chucked, the remaining face of the ring can be turned to the proper contour, thus cutting away the cen- ter portion. In work of this type take con- stant measurements - or better still, use a template - to guard against over or under cutting.

Turned Boxes

Turned boxes involve deep recessing together with a special system of working the lid and body of the box together as one unit. The inside of the lid is turned first. Next, the inside of the body is turned. A careful check must be made when turn- ing the lip of the body portion so that the lid will be a tight press fit. The lid is then pressed onto the body and the outer cir- cumference and face of the lid, together with the outer circumference of the body, are turned all at one time. This insures accurate matching of the two pieces. After the work is complete, the tight fit of the lid can be relieved by sanding the lip of the body.

Lid

Lids Body

Backing Block

Face Plate

45