User’s Guide

Basic

Appendix

Introduction

Environmentally friendly

Key benefits

Convenience

Supports various wireless network setting method

Operating System

Features by models

XPS printer drivera Samsung Easy Printer Manager

Select Software to Install window

SyncThru Admin Web Service

PS printer drivera

AirPrint Google Cloud Print

Optional tray Tray2

Machine does not print

Useful to know

Icon Text Description

About this user’s guide

General icons

Conventions

Important safety symbols

Safety information

Operating environment

Operating method

Installation / Moving

Maintenance / Checking

Supply usage

Safety information

Components

Machine overview

Front view

Rear view

M332xND/M382xD

Control panel overview

M382xND/M382xDW/M402xND

Turning on the machine

Installing the driver locally

Windows

Accessories Run

Collection Program optional. Then, click Next

From the Windows 8 Start Screen

Click Programs and Features

Reinstalling the driver

Machine’s basic settings

Menu Overview and Basic Setup

Menu overview

Accessing the menu

Menu overview

Overwrite

Wi-Fi Direct Wi-Fi Signal CLR Wi-Fi Set

Secured Job

Stored Job

Press System Setup

Machine’s basic settings

Machine’s basic settings

Paper width guide

Media and tray

Tray overview

Paper length guide

Loading paper in the tray

Tray 1 / optional tray

Multi-purpose or Manual feeder tray

Tips on using the Multi-purpose or Manual feeder tray

Media and tray

Plain

Manager select Switch to advanced mode Device Settings

Printing on special media

Types Tray Optional traya Multi-purpose or

Envelope

Labels

Transparency

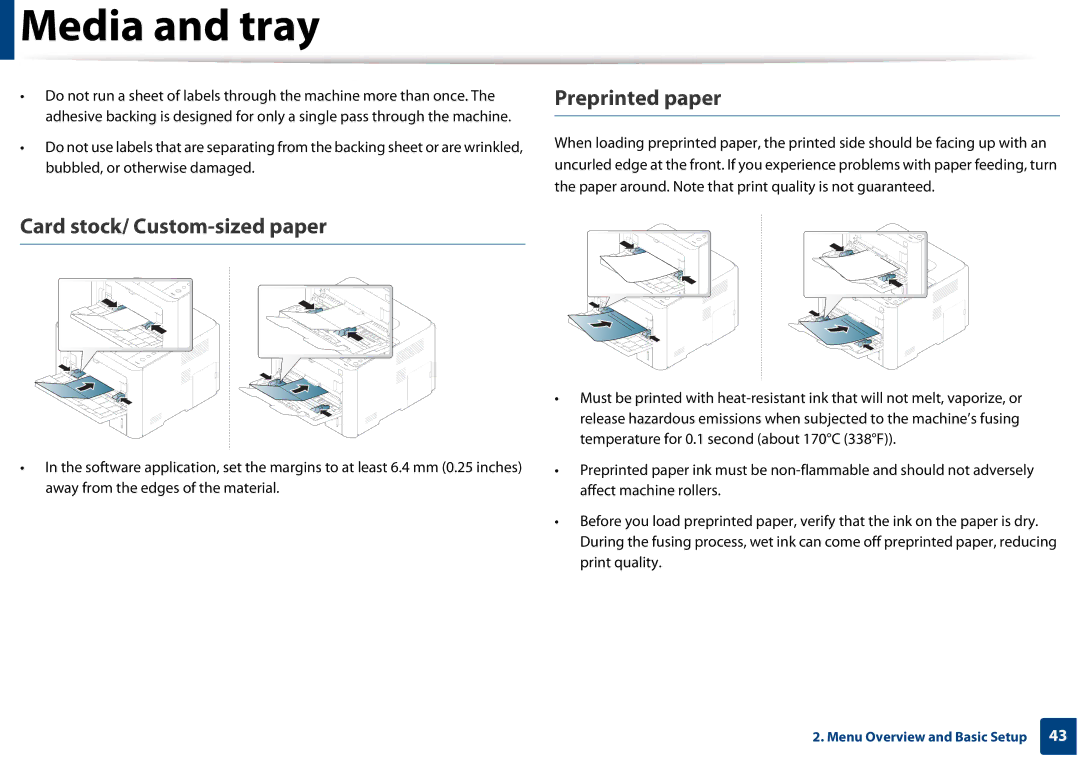

Card stock/ Custom-sized paper

Preprinted paper

Glossy Photo

Setting the paper size and type

Press Paper Size or Paper Type

Using the output support

Printing

Basic printing

Opening printing preferences

Canceling a print job

Click Properties or Preferences

Using help

Using a favorite setting

Eco printing

Setting Eco mode on the control panel

Eco options

Setting eco mode on the driver

Result simulator

Settings Machine Settings System Ram Disk

Starting secure printing from the SyncThru Web Service

Secure printing

Maintenance

Ordering supplies and accessories

Available consumables

Available consumables

Optional tray b

Available accessories

Accessory Function Part name Memory module a

Connector f

Available maintenance parts

Handling instructions

Storing the toner cartridge

Toner cartridge usage

Estimated cartridge life

Redistributing toner

M3320/M3820/M4020 series M3325/M3825/M4025 series

Toner cartridge

Replacing the toner cartridge

M3320 M3820 M4020 series

M3325 M3825 M4025 series

Replacing the imaging unit

Imaging unit

M3325/M3825/M4025 series

Precautions

Installing accessories

Setting Device Options

Select Device Options

Password Encryption

Upgrading a memory module

Installing accessories

Monitoring the supplies life

Setting the toner/imaging unit low alert

Cleaning the outside

Cleaning the machine

Cleaning the inside

Cleaning the machine

Cleaning the pickup roller

Tips for moving & storing your machine

Troubleshooting

Tips for avoiding paper jams

Tray

Clearing paper jams

Optional tray

Clearing paper jams

Manual feeder/multi-purpose tray

M332xND/M382xD series

M382xND/M382xDW/M402xND series

Inside the machine

M3320/M3820/M4020 series

M3325/M3825/M4025 series

Exit area

Clearing paper jams

Duplex unit area

Clearing paper jams

Color of the LED indicates the machines current status

Understanding the status LED

Status Red

Machine is in power save mode

Understanding the status LED

Paper Jam-related messages

Understanding display messages

Toner-related messages

Image unit

Message Meaning Suggested solutions Not Installed

Message Meaning Suggested solutions Replace new

Imaging unit-related messages

Network-related messages

Tray-related messages

Misc. messages

Tray1 roller

Message Meaning Suggested solutions Output bin Full

Remove paper

Fuser Soon

Appendix

General specifications

Specifications

Specifications

Print media specifications

Maximum size custom

Minimum Size custom e, f Multi-purposeor manual

System requirements

Microsoft Windows

Linux

Mac

Items Requirements Free HDD space GB 2 GB

Unix

Items Requirements

Network operating system

Items Specifications Network interface

Wireless security

Network environment

Regulatory information

Laser safety statement

Power saver China only

Ozone safety Recycling

United States of America only

Applicable in countries with separate collection systems

FCC information to the user

Intentional emitter per FCC Part

Canadian radio interference regulations

Federal Communications Commission FCC

United States of America

Russia only Germany only

FCC Statement for Wireless LAN use

Green and Yellow Earth

Important warning

Turkey only Thailand only

Replacing the Fitted Plug for UK Only

EC Certification

Approvals and Certifications

Declaration of conformity European countries

European states with restrictions on use

Wireless guidance

European states qualified under wireless approvals

Israel only Regulatory compliance statements

Regulatory information

China only

REV.1.00

Copyright

Advanced

Advanced

230

Software Installation

Click Continue

Installation for Mac

Type and click Continue

Or Print & Fax

Reinstallation for Mac

Installing the Unified Linux Driver

Installation for Linux

Reinstallation for Linux

Using a Network- Connected Machine

SyncThru Web Service

SyncThru Web Admin Service

SetIP wired network setup

Setting IP address

Wired network setup

IPv4 configuration using SetIP Windows

Printing a network configuration report

Network manager before proceeding

IPv4 configuration using SetIP Mac

Open /opt /Samsung /mfp /share /utils

Set IP Address button

Report

Software to Install window

Installing driver over the network

Read and accept The software End User License Agreement

Click Add a device

Silent installation Mode

Command-line Parameters

From Charms, select Settings Change PC settings Devices

Command- line Definition Description

Opens Printers and Faxes

Mac

Printers and Faxes folder

Click IP and select HP Jetdirect Socket in Protocol

Install the Linux driver and add network printer

Linux

Continue

Add a network printer

Installing the Unix printer driver package

It will open the Uninstall Printer Wizard

Uninstalling the printer driver package

Setting up the printer

Accept printername Enable printername

Installing driver over the network

From the control panel

IPv6 configuration

DHCPv6 address configuration

Activating IPv6

ID admin Password sec00000

From the SyncThru Web Service

Settings

IPv6 address configuration

Getting started

Wireless network setup

Wireless network name and network password

Understanding your network type

Mac user, see Access point via USB cable recommended on

Introducing wireless set up methods

Wi-Fi Direct setup

Choosing your type

Using the WPS button

Network Wi-Fi WPS

Items to prepare

Connecting in PIN mode

Connecting in PBC mode

Machines with a display screen

Machines without a display screen

Using the menu button

Re-connecting to a network

Disconnecting from a network

Canceling the connection process

Creating the infrastructure network

Access point via USB cable recommended

Setup using Windows

Items to prepare

Operation Mode Select Infrastructure

Finish

Ad hoc via USB cable

Creating the ad hoc network in Windows

Operation Mode Select ad hoc

For the Dhcp method

Setup using Mac

For the Static method

Current settings. Recommended. Then, click Next

Cable between the computer and machine

WEP Key Index

Creating the ad hoc network in Mac

Quit

Using a network cable

Using SyncThru Web Service

Printing a network configuration report

IP setting using SetIP Program Windows

Configuring the machine’s wireless network

Click Wireless Wizard

Setting the Wi-Fi Direct for mobile printing

Turning the Wi-Fi network on/off

Click Wireless Custom

From the machine Machines with a display screen

Setting up Wi-Fi Direct

Menu Network Wi-Fi Wi-Fi Direct on the control panel

From the USB cable-connected computerrecommended

From the network-connected computer

Setting up the mobile device

Problems during setup or driver installation

Troubleshooting for wireless network

Connecting Failure Ssid Not Found

Connecting Failure Assigning the IP address

Connecting Failure Invalid Security

Connecting Failure General Connection Error

Connecting Failure Connected Wired Network

Other problems

Wireless network setup

Supported Mobile OS

Samsung MobilePrint

Supported devices

Click AirPrint

Setting up AirPrint

AirPrint

Printing via AirPrint

AirPrint

Registering your Google account to the printer

Google Cloud Print

Click Register

Tap Click here to Print

Printing with Google Cloud Print

Click Finish printer registration

Click Manage your printers

Select Print with Google Cloud Print

Before you begin reading

Useful Setting Menus

Before you begin reading a chapter

Account

Information

Portrait Orientation Landscape Description

Layout

Long Edge Duplex Short Edge

MP Tray/ Tray

Paper

Graphic

Clock Mode a

System Setup

Date & Time a

SkipBlankPage

Auto Power Off On Timeout

Emulation

TCP/IP IPv4 TCP/IP IPv6

Wi-Fi

Network

Option Description

You can activate or deactivate the following protocols

Job Management

Special Features

Altitude adjustment

Key Assigned numbers, letters, or characters

Entering various characters

Entering alphanumeric characters

Keypad letters and numbers

Select Control Panel Devices and Printers

Printing features

Changing the default print settings

Setting your machine as a default machine

Printing to a file PRN

Using advanced print features

Poster Printing

Understanding special printer features

Booklet Printinga Double-sided Printing Description

Watermark

Document

Overlay a

Creating a

Editing a watermark

Deleting a

List box

Using a page overlay

Printing Preferences window, click the Advanced tab

Print Modeb

Job Accountingb

From the Start menu select Programs or All Programs

What is Direct Printing Utility?

Using Direct Printing Utility

Printing

Printing a document

Using the right-click menu

Mac printing

Printing multiple pages on one sheet

Changing printer settings

Printing on both sides of the paper

Printing from applications

Using help

Linux printing

Lp -d printer name -o option file name

Configuring Printer Properties

Open the Unified Driver Configurator

Printing files

General tab

Changing the machine settings

Proceeding the print job

Unix printing

Margins tab

Printer-Specific Settings tab

Image tab

Text tab

From the printer driver

Using optional device features

Using optional device features

Samsung AnyWeb Print

Accessing management

From the Start menu, select Programs or All Programs

Accessing management tools

Find Samsung Printers

Easy Capture Manager

Samsung AnyWeb Print

Easy Eco Driver

How to use

Logging into SyncThru Web Service

Using SyncThru Web Service

Maintenance tab

Settings tab

Information tab Security tab

Setting the system administrator’s information

Mail notification setup

Using SyncThru Web Service

Understanding Samsung Easy Printer Manager

Using Samsung Easy Printer Manager

Troubleshooting button This button opens

Advanced settings user interface overview

To the advanced settings user interface see

Alert Settings Windows only

Device Settings

Job Accounting

Icon Mean Description

Using Samsung Printer Status

Samsung Printer Status overview

Preferences, click the Basic tab Printer Status button

Close

Option

Order Supplies

User’s Guide

Understanding the Samsung Printer Experience

Using Samsung Printer Experience

Printer Information

Printing from Windows

Basic printing

Opening more settings

Cancelling a print job

Click More settings

Basic tab

Eco settings

Paper settings

Layout settings

Job Accounting

Scanning from Samsung Printer Experience

Scanning from Windows

Security tab

Click Scan and save the image

Opening Unified Driver Configurator

Using the Linux Unified Driver Configurator

Printers tab

Printers configuration

Switches to Printers configuration

Shows all of the installed machines

Classes tab

Switches to Ports configuration

Ports configuration

Troubleshooting

Paper feeding problems

Power and cable connecting problems

Printing problems

Machine prints, but

Machine selects print

Print job is extremely

Slow Half the page is blank

Photos is not good

Condition Possible cause Suggested solutions

Pages print, but they are

Blank

Printing problems

Condition Suggested solutions Light or faded print

Printing quality problems

White Spots

Condition

Toner specks

Dropouts

Black or color background

Condition Suggested solutions Vertical lines

Toner smear

Characters or pictures

Background scatter

Curl or wave

Back of printouts are dirty

Condition Suggested solutions Wrinkles or creases

Solid color or black pages

Character voids

Condition Suggested solutions Loose toner

Horizontal stripes

Sheets

Condition Suggested solutions Curl

An unknown image

Repetitively appears on a few

Common Windows problems

Operating system problems

Condition Suggested solutions

Common Mac problems

During cover page printing Cover

Common Linux problems

Common PostScript problems

Cote D’ Ivoire

Country/Region Customer Care Center WebSite

Cyprus

Hong Kong

Nicaragua

Russia

802.11b/g/n

Access point

802.11

AppleTalk

Control Panel

Default

Coverage

Collation

Dot Matrix Printer

Duplex

Duty Cycle

Fuser Unit

EtherTalk

Emulation

Ethernet

Mass storage device HDD

Gateway

Grayscale

Halftone

IPM

ITU-T No chart

Modem

MAC address

Originals

NetWare

Print Media

Resolution

PostScript

Printer Driver

Toner Cartridge

Subnet Mask

Watermark

UNC Path

WPA-PSK

Index

Machine overview

46 S

Unix

Media and tray

Media and tray