CHAPTER 3. MECHANISM BLOCKS

[1] General description

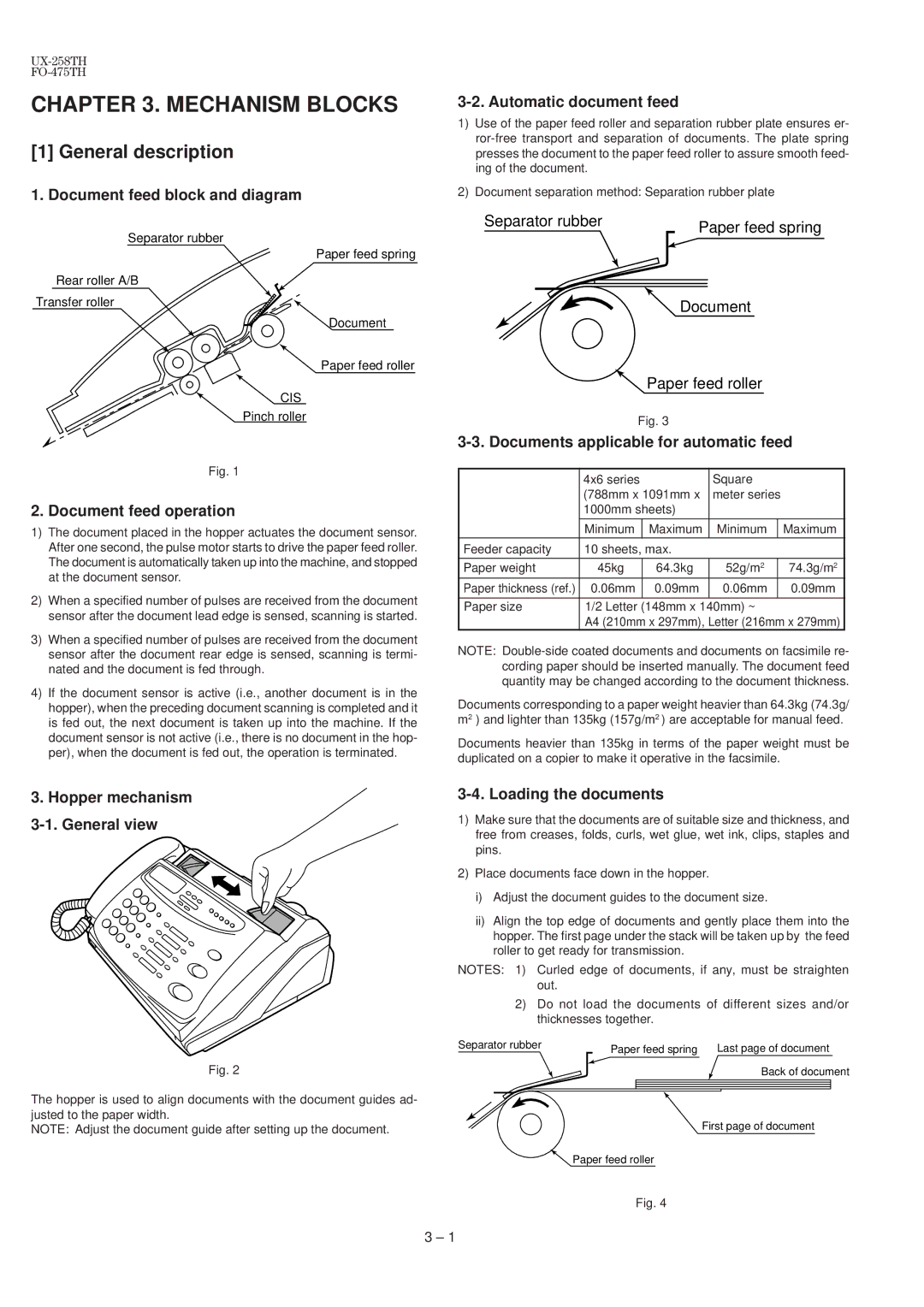

1. Document feed block and diagram

Separator rubber

Paper feed spring

Rear roller A/B

Transfer roller

Document

Paper feed roller

CIS

Pinch roller

Fig. 1

2. Document feed operation

1)The document placed in the hopper actuates the document sensor. After one second, the pulse motor starts to drive the paper feed roller. The document is automatically taken up into the machine, and stopped at the document sensor.

2)When a specified number of pulses are received from the document sensor after the document lead edge is sensed, scanning is started.

3)When a specified number of pulses are received from the document sensor after the document rear edge is sensed, scanning is termi- nated and the document is fed through.

4)If the document sensor is active (i.e., another document is in the hopper), when the preceding document scanning is completed and it is fed out, the next document is taken up into the machine. If the document sensor is not active (i.e., there is no document in the hop- per), when the document is fed out, the operation is terminated.

3.Hopper mechanism

Fig. 2

The hopper is used to align documents with the document guides ad- justed to the paper width.

NOTE: Adjust the document guide after setting up the document.

3-2. Automatic document feed

1)Use of the paper feed roller and separation rubber plate ensures er-

2)Document separation method: Separation rubber plate

Separator rubber | Paper feed spring |

|

Document

Paper feed roller

Fig. 3

3-3. Documents applicable for automatic feed

| 4x6 series |

| Square |

| |

| (788mm x 1091mm x | meter series |

| ||

| 1000mm sheets) |

|

|

| |

|

|

|

|

| |

| Minimum | Maximum | Minimum |

| Maximum |

Feeder capacity | 10 sheets, max. |

|

|

| |

|

|

|

|

|

|

Paper weight | 45kg | 64.3kg | 52g/m2 |

| 74.3g/m2 |

Paper thickness (ref.) | 0.06mm | 0.09mm | 0.06mm |

| 0.09mm |

|

|

|

|

|

|

Paper size | 1/2 Letter (148mm x 140mm) ~ |

| |||

| A4 (210mm x 297mm), Letter (216mm x 279mm) | ||||

NOTE:

Documents corresponding to a paper weight heavier than 64.3kg (74.3g/ m2 ) and lighter than 135kg (157g/m2 ) are acceptable for manual feed.

Documents heavier than 135kg in terms of the paper weight must be duplicated on a copier to make it operative in the facsimile.

3-4. Loading the documents

1)Make sure that the documents are of suitable size and thickness, and free from creases, folds, curls, wet glue, wet ink, clips, staples and pins.

2)Place documents face down in the hopper.

i)Adjust the document guides to the document size.

ii)Align the top edge of documents and gently place them into the hopper. The first page under the stack will be taken up by the feed roller to get ready for transmission.

NOTES: 1) Curled edge of documents, if any, must be straighten out.

2)Do not load the documents of different sizes and/or thicknesses together.

Separator rubber | Paper feed spring | Last page of document |

| ||

|

| Back of document |

|

| First page of document |

| Paper feed roller |

|

Fig. 4

3 – 1