Industry Automation and Drive Technologies - SCE

3.4Recording and Reading Out Recognition Values in a PROFINET IO Environment

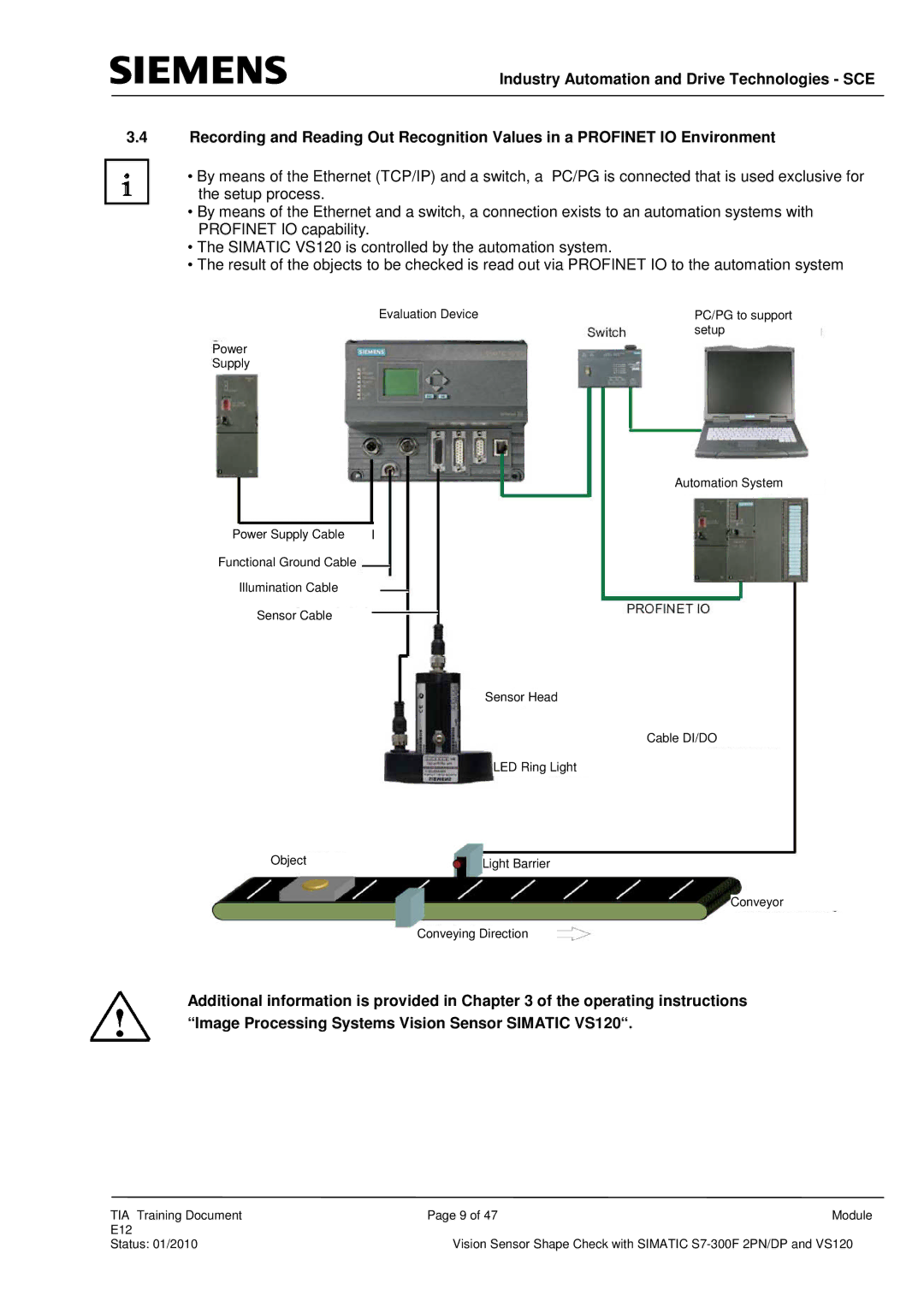

•By means of the Ethernet (TCP/IP) and a switch, a PC/PG is connected that is used exclusive for the setup process.

•By means of the Ethernet and a switch, a connection exists to an automation systems with PROFINET IO capability.

•The SIMATIC VS120 is controlled by the automation system.

•The result of the objects to be checked is read out via PROFINET IO to the automation system

Evaluation Device |

| PC/PG to support |

|

| setup |

Power

Supply

Automation System

Power Supply Cable

Functional Ground Cable

Illumination Cable

Sensor Cable

Sensor Head

Cable DI/DO

LED Ring Light

Object | Light Barrier |

|

Conveyor

Conveying Direction

Additional information is provided in Chapter 3 of the operating instructions “Image Processing Systems Vision Sensor SIMATIC VS120“.

TIA Training Document | Page 9 of 47 | Module |

E12 |

|

|

Status: 01/2010 | Vision Sensor Shape Check with SIMATIC | |