M4557 - Model 9210 Nitriding Controller

Manual Event Control

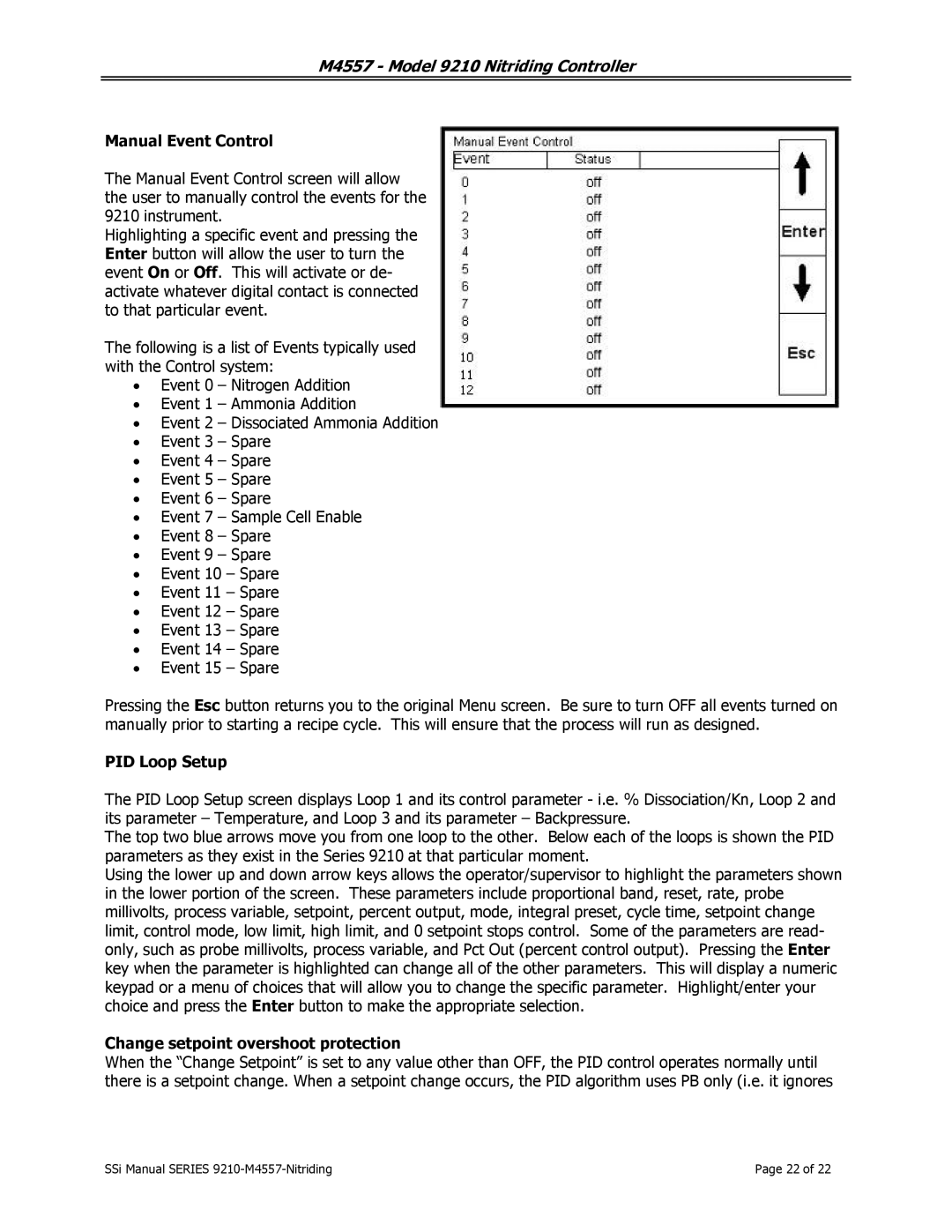

The Manual Event Control screen will allow the user to manually control the events for the 9210 instrument.

Highlighting a specific event and pressing the Enter button will allow the user to turn the event On or Off. This will activate or de- activate whatever digital contact is connected to that particular event.

The following is a list of Events typically used with the Control system:

•Event 0 – Nitrogen Addition

•Event 1 – Ammonia Addition

•Event 2 – Dissociated Ammonia Addition

•Event 3 – Spare

•Event 4 – Spare

•Event 5 – Spare

•Event 6 – Spare

•Event 7 – Sample Cell Enable

•Event 8 – Spare

•Event 9 – Spare

•Event 10 – Spare

•Event 11 – Spare

•Event 12 – Spare

•Event 13 – Spare

•Event 14 – Spare

•Event 15 – Spare

Pressing the Esc button returns you to the original Menu screen. Be sure to turn OFF all events turned on manually prior to starting a recipe cycle. This will ensure that the process will run as designed.

PID Loop Setup

The PID Loop Setup screen displays Loop 1 and its control parameter - i.e. % Dissociation/Kn, Loop 2 and its parameter – Temperature, and Loop 3 and its parameter – Backpressure.

The top two blue arrows move you from one loop to the other. Below each of the loops is shown the PID parameters as they exist in the Series 9210 at that particular moment.

Using the lower up and down arrow keys allows the operator/supervisor to highlight the parameters shown in the lower portion of the screen. These parameters include proportional band, reset, rate, probe millivolts, process variable, setpoint, percent output, mode, integral preset, cycle time, setpoint change limit, control mode, low limit, high limit, and 0 setpoint stops control. Some of the parameters are read- only, such as probe millivolts, process variable, and Pct Out (percent control output). Pressing the Enter key when the parameter is highlighted can change all of the other parameters. This will display a numeric keypad or a menu of choices that will allow you to change the specific parameter. Highlight/enter your choice and press the Enter button to make the appropriate selection.

Change setpoint overshoot protection

When the “Change Setpoint” is set to any value other than OFF, the PID control operates normally until there is a setpoint change. When a setpoint change occurs, the PID algorithm uses PB only (i.e. it ignores

SSi Manual SERIES | Page 22 of 22 |