M4557 - Model 9210 Nitriding Controller

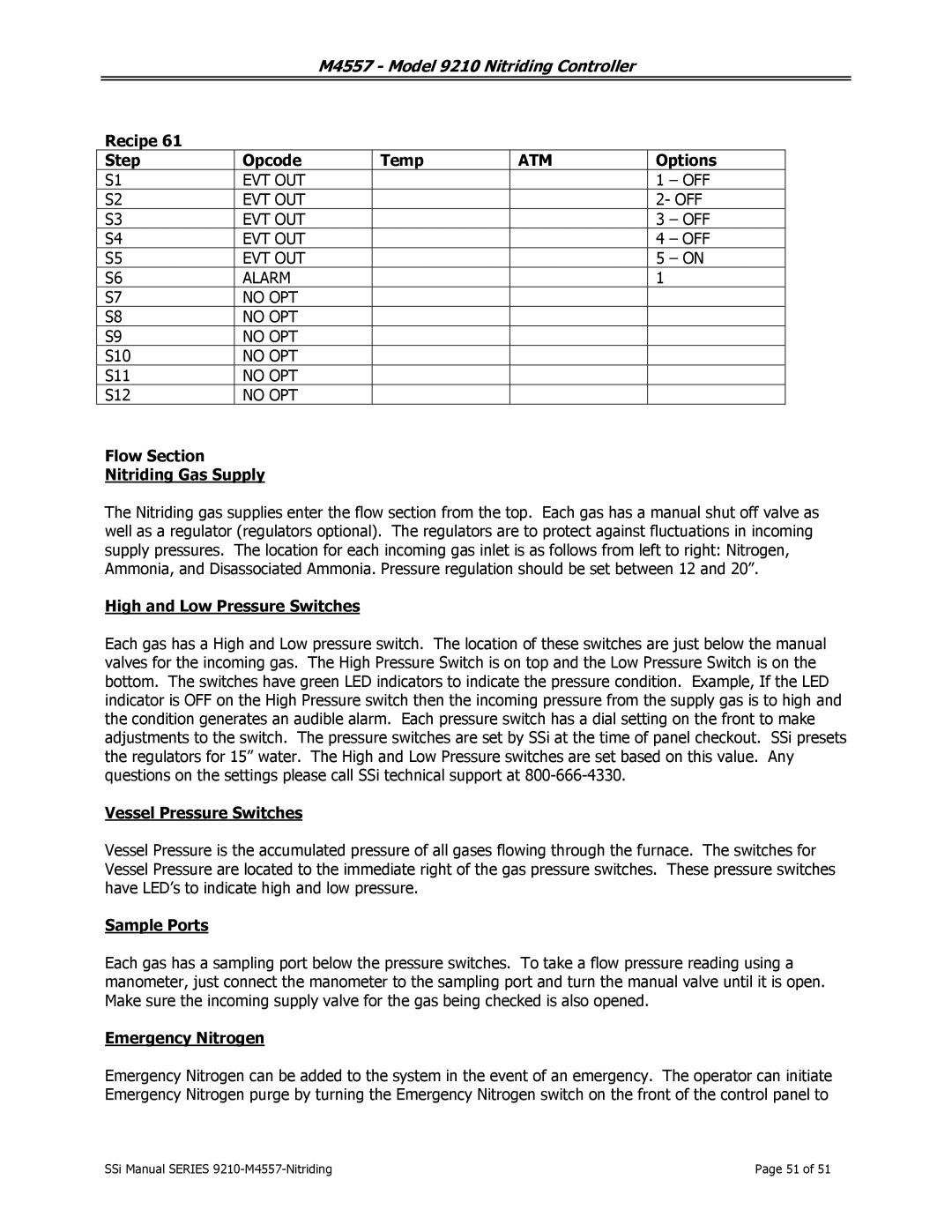

Recipe 61

Step | Opcode | Temp | ATM | Options | |

S1 | EVT OUT |

|

| 1 | – OFF |

S2 | EVT OUT |

|

| 2- OFF | |

S3 | EVT OUT |

|

| 3 | – OFF |

S4 | EVT OUT |

|

| 4 | – OFF |

S5 | EVT OUT |

|

| 5 | – ON |

S6 | ALARM |

|

| 1 |

|

S7 | NO OPT |

|

|

|

|

S8 | NO OPT |

|

|

|

|

S9 | NO OPT |

|

|

|

|

S10 | NO OPT |

|

|

|

|

S11 | NO OPT |

|

|

|

|

S12 | NO OPT |

|

|

|

|

Flow Section

Nitriding Gas Supply

The Nitriding gas supplies enter the flow section from the top. Each gas has a manual shut off valve as well as a regulator (regulators optional). The regulators are to protect against fluctuations in incoming supply pressures. The location for each incoming gas inlet is as follows from left to right: Nitrogen, Ammonia, and Disassociated Ammonia. Pressure regulation should be set between 12 and 20”.

High and Low Pressure Switches

Each gas has a High and Low pressure switch. The location of these switches are just below the manual valves for the incoming gas. The High Pressure Switch is on top and the Low Pressure Switch is on the bottom. The switches have green LED indicators to indicate the pressure condition. Example, If the LED indicator is OFF on the High Pressure switch then the incoming pressure from the supply gas is to high and the condition generates an audible alarm. Each pressure switch has a dial setting on the front to make adjustments to the switch. The pressure switches are set by SSi at the time of panel checkout. SSi presets the regulators for 15” water. The High and Low Pressure switches are set based on this value. Any questions on the settings please call SSi technical support at

Vessel Pressure Switches

Vessel Pressure is the accumulated pressure of all gases flowing through the furnace. The switches for Vessel Pressure are located to the immediate right of the gas pressure switches. These pressure switches have LED’s to indicate high and low pressure.

Sample Ports

Each gas has a sampling port below the pressure switches. To take a flow pressure reading using a manometer, just connect the manometer to the sampling port and turn the manual valve until it is open. Make sure the incoming supply valve for the gas being checked is also opened.

Emergency Nitrogen

Emergency Nitrogen can be added to the system in the event of an emergency. The operator can initiate Emergency Nitrogen purge by turning the Emergency Nitrogen switch on the front of the control panel to

SSi Manual SERIES | Page 51 of 51 |