(to the next page)

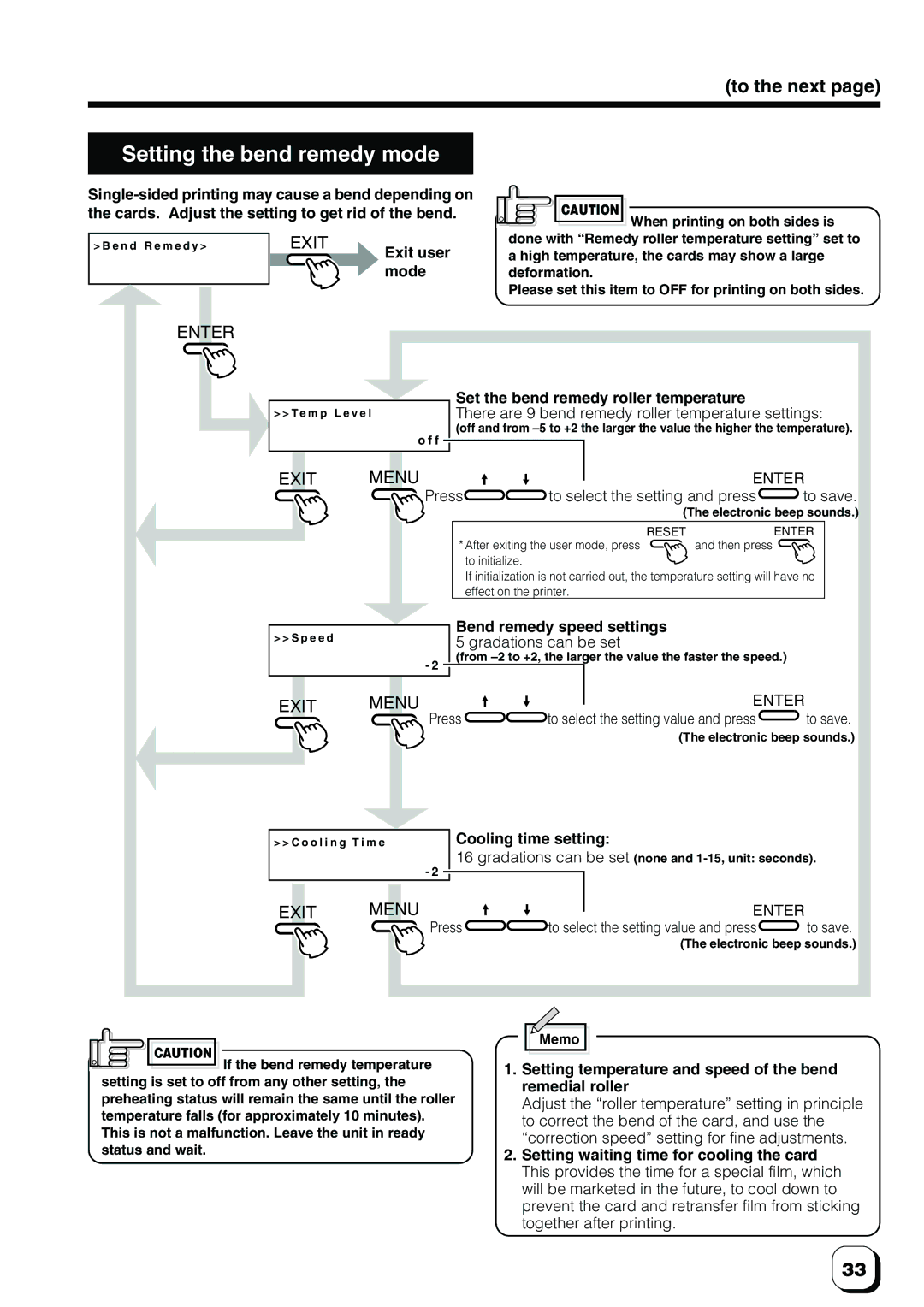

Setting the bend remedy mode

> B e n d R e m e d y > | EXIT | Exit user |

|

| |

|

| mode |

ENTER

CAUTION

![]() When printing on both sides is done with “Remedy roller temperature setting” set to a high temperature, the cards may show a large deformation.

When printing on both sides is done with “Remedy roller temperature setting” set to a high temperature, the cards may show a large deformation.

Please set this item to OFF for printing on both sides.

Set the bend remedy roller temperature

> > T e m p L e v e l | There are 9 bend remedy roller temperature settings: |

(off and from

| o f f |

|

|

|

EXIT | MENU |

| ENTER | |

| Press | to select the setting and press | to save. | |

|

| (The electronic beep sounds.) | ||

|

| RESET |

| ENTER |

| * After exiting the user mode, press | and then press |

| |

|

| to initialize. |

|

|

|

| If initialization is not carried out, the temperature setting will have no | ||

|

| effect on the printer. |

|

|

Bend remedy speed settings

> > S p e e d | 5 gradations can be set |

| (from |

| |

| - 2 |

|

|

EXIT | MENU | ENTER | to save. |

| Press | to select the setting value and press | |

|

| (The electronic beep sounds.) | |

> > C o o l i n g T i m e |

|

| Cooling time setting: | |

| - 2 |

| 16 gradations can be set (none and | |

|

|

|

| |

|

|

|

| |

EXIT | MENU | ENTER | to save. |

| Press | to select the setting value and press | |

|

| (The electronic beep sounds.) | |

|

|

| Memo |

| |

CAUTION |

|

|

| ||

If the bend remedy temperature |

|

|

| ||

1. Setting temperature and speed of the bend | |||||

| |||||

| |||||

setting is set to off from any other setting, the |

| remedial roller | |||

preheating status will remain the same until the roller |

| Adjust the “roller temperature” setting in principle | |||

temperature falls (for approximately 10 minutes). |

| to correct the bend of the card, and use the | |||

This is not a malfunction. Leave the unit in ready |

| “correction speed” setting for fine adjustments. | |||

status and wait. | 2. Setting waiting time for cooling the card | ||||

|

|

| This provides the time for a special film, which | ||

|

|

| will be marketed in the future, to cool down to | ||

|

|

| prevent the card and retransfer film from sticking | ||

|

|

| together after printing. | ||

33