Chateau™ Decorative Gas Appliance

Zero clearance sleeve is only required for combustible walls.

STEP 3

Slide the zero clearance sleeve through the wall and install the firestop on the inside surface of the wall. Secure with four (4) #8 sheet metal screws.

STEP 4

Place fireplace into position. (Fig. 21) Measure the vertical height (X) required from the base of the flue collars to the center of the wall opening. NOTE: If using the SK8DVSK Kit, the vertical section of pipe is tele- scopic and could provide adjustment from 24” up to 40” (610mm to 1016mm). Through the wall section shipped with the starter kit will not be used when going through the wall.

STEP 5

Tape the inner and outer flue collars of the fireplace using UL approved metal adhesive tape to ensure the joints are sealed. Attach an appropriate length of vent pipe to the fireplace. Follow with the installation of the inner and outer elbow, tape elbow joints and secure joints as described on Page 11.

the wall plate to weatherproof. (Fig. 25) As an alterna- tive to screwing the termination directly to the wall you may also use expanding plugs or an approved exterior construction adhesive.

Installing the 38S2VDK Door

When installing the DVT38S2 on an outside wall, the following steps must be taken into consideration. Fail- ure to do so will result in a major reconstruction and CFM Corporation will not be responsible for costs associated with incorrect installation.

• If the unit is to be installed flush with the wall, a 1/4” |

(6 mm) clearance is required on both sides and top |

of surround around the glass frame assembly in |

order for the door to be accessible. (Refer to Page 4, |

Fig. 2) |

• If the unit is recessed 3/4” (19 mm) from the wall, |

then no extra clearances are needed around the sur- |

round. |

• The unit must be installed with the stationary glass |

facing the outside (control panel assembly will be |

located on the left hand side of the unit when facing |

the unit from inside the house). |

• The control panel assembly must only be installed |

2” ![]()

![]() (51mm)

(51mm)

1”

(25mm)

Min.

16¹⁄₄” x 16¹⁄₄”

(413 x 413mm) Opening

1” (25mm) Min.

FP1461

on an inside wall. |

Package contents:

•1, Glass frame assembly

•2, Brackets

•2, Short machine screws

•2, Long machine screws

•4, sheet metal screws

Installation Procedure

1.If the unit is installed flush with the wall, a high tem- perature sealant must be applied to seal around the surround around the glass frame assembly 3/4” (19 mm) of the front edge of the surround. (Fig. 26)

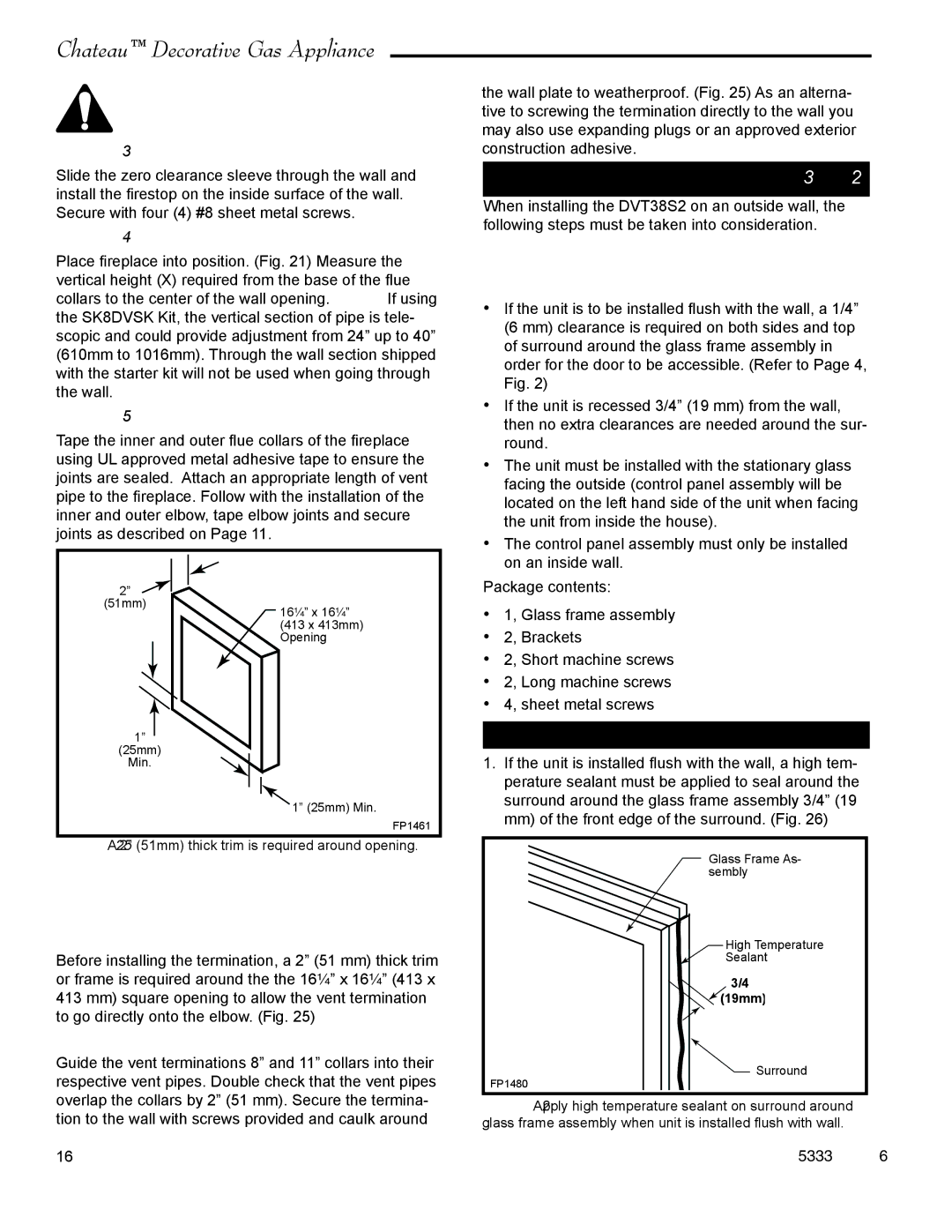

Fig. 25 A 2” (51mm) thick trim is required around opening.

Sealing firestop gaps with high temperature sealant will restrict cold air being drawn in around fire- place.

STEP 6

Before installing the termination, a 2” (51 mm) thick trim or frame is required around the the 16¹⁄₄” x 16¹⁄₄” (413 x 413 mm) square opening to allow the vent termination to go directly onto the elbow. (Fig. 25)

STEP 7

Guide the vent terminations 8” and 11” collars into their respective vent pipes. Double check that the vent pipes overlap the collars by 2” (51 mm). Secure the termina- tion to the wall with screws provided and caulk around

Glass Frame As- sembly

High Temperature

Sealant

3/4"

![]() (19mm)

(19mm)

![]() Surround

Surround

FP1480

Fig. 26 Apply high temperature sealant on surround around glass frame assembly when unit is installed flush with wall.

16 | 20009543 |