•A 2’ (610 mm) vertical section must be installed before any offset. A maximum of 20’ (6.1 m) horizon- tal and three (3) 90° elbows may be installed with a minimum of 12’ (3.66 m) vertical section above the flue collar of the unit. (Fig. 32)

•Up to two (2) 30° or 45° elbows may be used within the horizontal run. For each 30° or 45° elbow used on the horizontal level the maximum horizontal length must be reduced by 18” (457 mm).

Example: Maximum horizontal length

0 x 30° or 45° elbows = 10’ (3 m)

1x 30° or 45° elbows = 8’6” (2.6 m)

2 x 30° or 45° elbows = 7’ (2.1 m)

•A minimum of a 12’ (3.7 m) vertical rise.

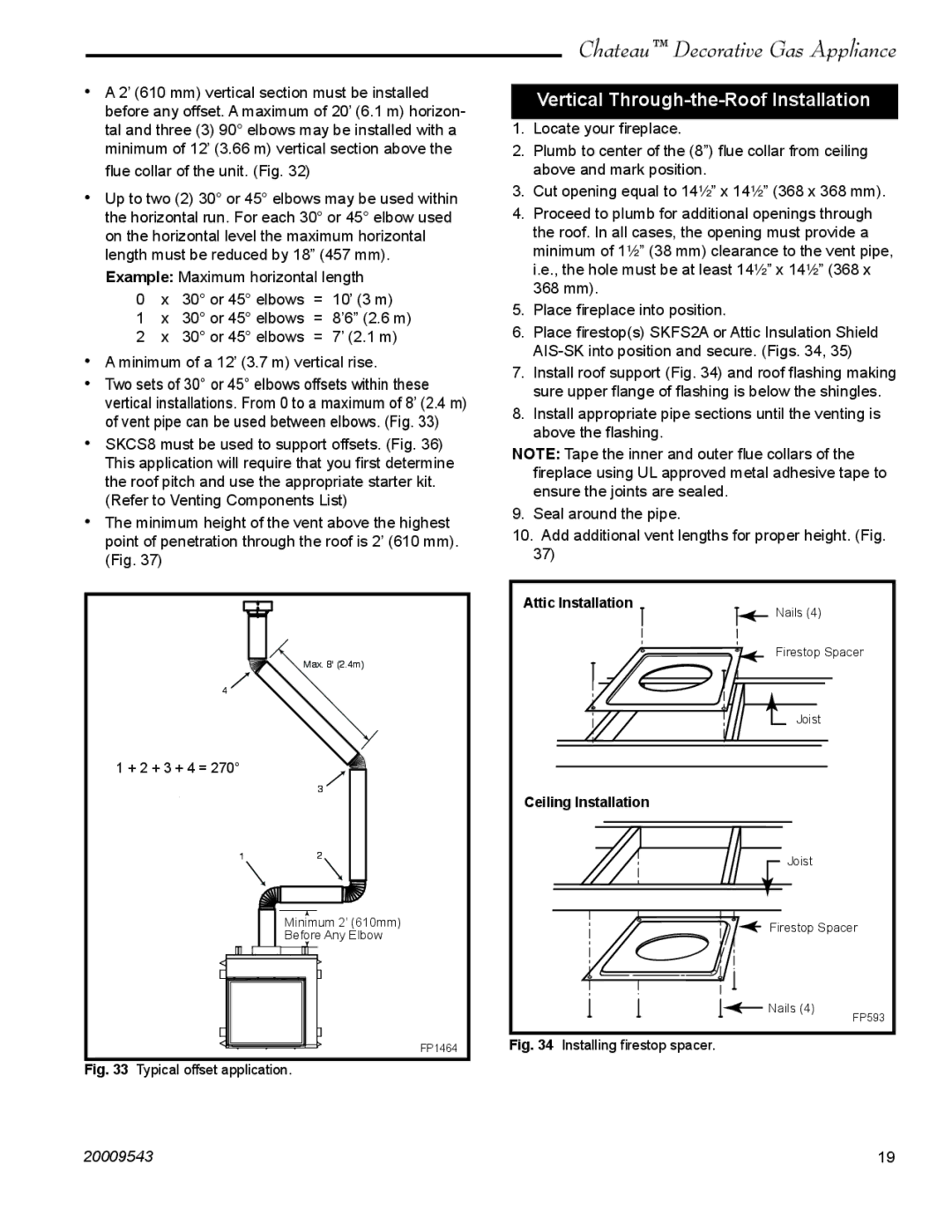

•Two sets of 30° or 45° elbows offsets within these vertical installations. From 0 to a maximum of 8’ (2.4 m) of vent pipe can be used between elbows. (Fig. 33)

•SKCS8 must be used to support offsets. (Fig. 36) This application will require that you first determine the roof pitch and use the appropriate starter kit. (Refer to Venting Components List)

•The minimum height of the vent above the highest point of penetration through the roof is 2’ (610 mm). (Fig. 37)

Max. 8' (2.4m)

4

1 + 2 + 3 + 4 = 270°

3

12

Minimum 2’ (610mm)

Before Any Elbow

Chateau™ Decorative Gas Appliance

Vertical Through-the-Roof Installation

1.Locate your fireplace.

2.Plumb to center of the (8”) flue collar from ceiling above and mark position.

3.Cut opening equal to 14¹⁄₂” x 14¹⁄₂” (368 x 368 mm).

4.Proceed to plumb for additional openings through the roof. In all cases, the opening must provide a minimum of 1¹⁄₂” (38 mm) clearance to the vent pipe, i.e., the hole must be at least 14¹⁄₂” x 14¹⁄₂” (368 x 368 mm).

5.Place fireplace into position.

6.Place firestop(s) SKFS2A or Attic Insulation Shield

7.Install roof support (Fig. 34) and roof flashing making sure upper flange of flashing is below the shingles.

8.Install appropriate pipe sections until the venting is above the flashing.

NOTE: Tape the inner and outer flue collars of the fireplace using UL approved metal adhesive tape to ensure the joints are sealed.

9.Seal around the pipe.

10.Add additional vent lengths for proper height. (Fig. 37)

Attic Installation

Nails (4)

Firestop Spacer

Joist

Ceiling Installation

Joist

Firestop Spacer

Nails (4)

FP593

FP1245a

FP1464

Fig. 34 Installing firestop spacer.

Fig. 33 Typical offset application.

20009543 | 19 |