VHX SERIES STEAMERS - GENERAL

WATER CONDITIONING |

| SPECIFICATIONS |

Furnishing the boiler with treated water to reduce scale formation is important. Scale formation will reduce steam output, cause premature component failure, and shorten equipment life. Most water supplies contain scale producing minerals such as Calcium and Magnesium. As steam is generated, the minerals remain and dissolve into the water. As the concentration of these minerals increases past a certain point, they precipitate from the water and coat the inside of the boiler, heating elements, and water level sensors. Because of the high temperature of these surfaces, the precipitated minerals bake onto them and become very difficult to remove.

This may cause several problems:

1.Reduced heat transfer efficiency.

2.Premature heating element failures.

3.False readings from water level sensors.

These problems are common to any manufacturer's steamer regardless of design, but they can all be minimized by furnishing the boiler with treated water.

Other factors affecting steam generation are iron content, amount of chlorination and dissolved gases.

The desired water properties can best be achieved by using a properly maintained water treatment

system.

The water level probes in the boiler use ions in the water to detect the water level. Do not use fully demineralized or

The use of strainers or non approved filters will not remove minerals from the water.

Water supplies vary from state to state and from locations within a state. Therefore, a water treatment specialist should be consulted before the installation of any steam generating equipment.

Steamers that operate over a long period of time without the benefit of a water treatment system, which have developed a heavy scale build up, should be cleaned before using the system.

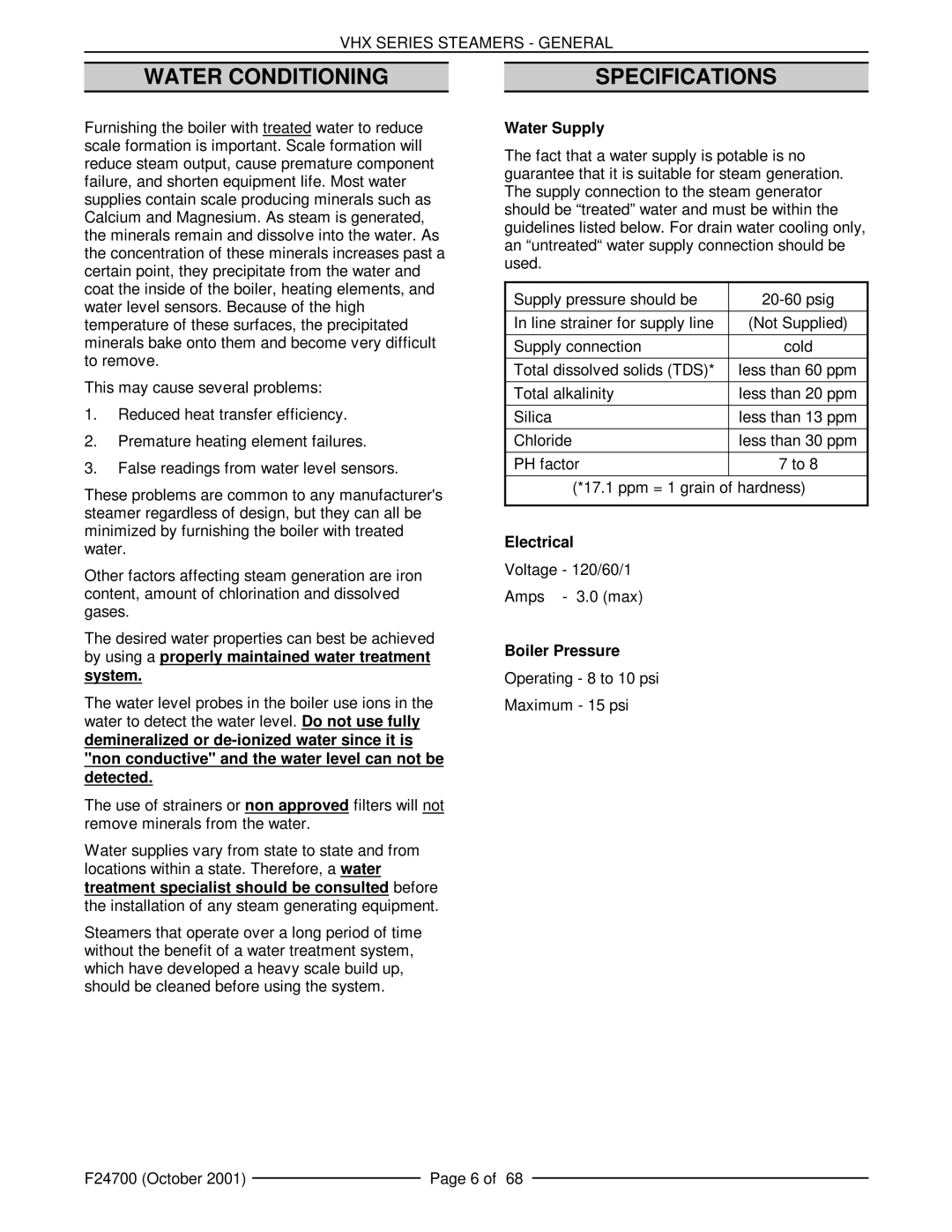

Water Supply

The fact that a water supply is potable is no guarantee that it is suitable for steam generation. The supply connection to the steam generator should be “treated” water and must be within the guidelines listed below. For drain water cooling only, an “untreated“ water supply connection should be used.

Supply pressure should be | |

|

|

In line strainer for supply line | (Not Supplied) |

|

|

Supply connection | cold |

|

|

Total dissolved solids (TDS)* | less than 60 ppm |

|

|

Total alkalinity | less than 20 ppm |

|

|

Silica | less than 13 ppm |

|

|

Chloride | less than 30 ppm |

|

|

PH factor | 7 to 8 |

|

|

(*17.1 ppm = 1 grain of hardness) | |

|

|

Electrical |

|

Voltage - 120/60/1 |

|

Amps - 3.0 (max) |

|

Boiler Pressure |

|

Operating - 8 to 10 psi |

|

Maximum - 15 psi |

|

F24700 (October 2001) |

| Page 6 of 68 |

|