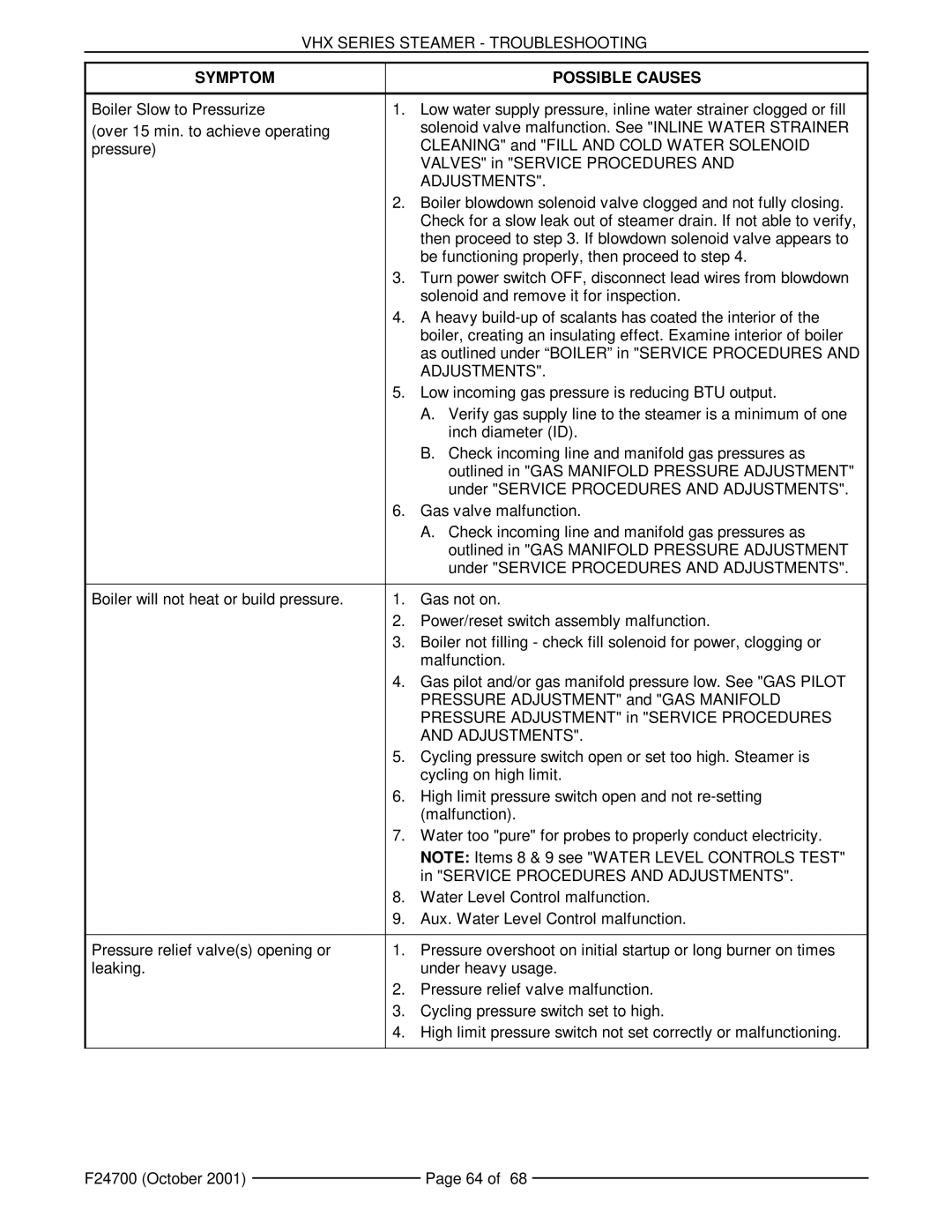

VHX SERIES STEAMER - TROUBLESHOOTING

SYMPTOM |

| POSSIBLE CAUSES |

|

|

|

Boiler Slow to Pressurize | 1. | Low water supply pressure, inline water strainer clogged or fill |

(over 15 min. to achieve operating |

| solenoid valve malfunction. See "INLINE WATER STRAINER |

pressure) |

| CLEANING" and "FILL AND COLD WATER SOLENOID |

|

| VALVES" in "SERVICE PROCEDURES AND |

|

| ADJUSTMENTS". |

| 2. | Boiler blowdown solenoid valve clogged and not fully closing. |

|

| Check for a slow leak out of steamer drain. If not able to verify, |

|

| then proceed to step 3. If blowdown solenoid valve appears to |

|

| be functioning properly, then proceed to step 4. |

| 3. | Turn power switch OFF, disconnect lead wires from blowdown |

|

| solenoid and remove it for inspection. |

| 4. | A heavy |

|

| boiler, creating an insulating effect. Examine interior of boiler |

|

| as outlined under “BOILER” in "SERVICE PROCEDURES AND |

|

| ADJUSTMENTS". |

| 5. | Low incoming gas pressure is reducing BTU output. |

|

| A. Verify gas supply line to the steamer is a minimum of one |

|

| inch diameter (ID). |

|

| B. Check incoming line and manifold gas pressures as |

|

| outlined in "GAS MANIFOLD PRESSURE ADJUSTMENT" |

|

| under "SERVICE PROCEDURES AND ADJUSTMENTS". |

| 6. | Gas valve malfunction. |

|

| A. Check incoming line and manifold gas pressures as |

|

| outlined in "GAS MANIFOLD PRESSURE ADJUSTMENT |

|

| under "SERVICE PROCEDURES AND ADJUSTMENTS". |

|

|

|

Boiler will not heat or build pressure. | 1. | Gas not on. |

| 2. | Power/reset switch assembly malfunction. |

| 3. | Boiler not filling - check fill solenoid for power, clogging or |

|

| malfunction. |

| 4. | Gas pilot and/or gas manifold pressure low. See "GAS PILOT |

|

| PRESSURE ADJUSTMENT" and "GAS MANIFOLD |

|

| PRESSURE ADJUSTMENT" in "SERVICE PROCEDURES |

|

| AND ADJUSTMENTS". |

| 5. | Cycling pressure switch open or set too high. Steamer is |

|

| cycling on high limit. |

| 6. | High limit pressure switch open and not |

|

| (malfunction). |

| 7. | Water too "pure" for probes to properly conduct electricity. |

|

| NOTE: Items 8 & 9 see "WATER LEVEL CONTROLS TEST" |

|

| in "SERVICE PROCEDURES AND ADJUSTMENTS". |

| 8. | Water Level Control malfunction. |

| 9. | Aux. Water Level Control malfunction. |

|

|

|

Pressure relief valve(s) opening or | 1. | Pressure overshoot on initial startup or long burner on times |

leaking. |

| under heavy usage. |

| 2. | Pressure relief valve malfunction. |

| 3. | Cycling pressure switch set to high. |

| 4. | High limit pressure switch not set correctly or malfunctioning. |

|

|

|

F24700 (October 2001) |

| Page 64 of 68 |

|