VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: READ AND FOLLOW THE INSTRUCTIONS FOR THE

5.Mix deliming solution according to the instructions for the chemical being used.

NOTE: Boiler water capacity is approximately seven gallons.

NOTE: If deliming solution comes in contact with steamer components, lightly rinse off with clean water.

A.Turn OFF water supply.

B.Turn power switch ON to close the drain valve.

C.Pour deliming solution into the boiler shell.

6.Install a new gasket on the hand hole plate then position and tighten the plate to the boiler.

7.Ensure cooking compartment timers are OFF.

8.Turn power switch ON and open water supply valve.

9.Allow the boiler to reach operating pressure and run for 90 minutes or per the instructions for the deliming chemical in use.

A.Turn power switch OFF and allow the boiler to completely drain.

B.Turn power switch ON to refill boiler and allow to heat until fully pressurized.

10.Steps 9A and 9B must be repeated three times to thoroughly rinse the boiler.

11.Steamer is now ready for normal operation.

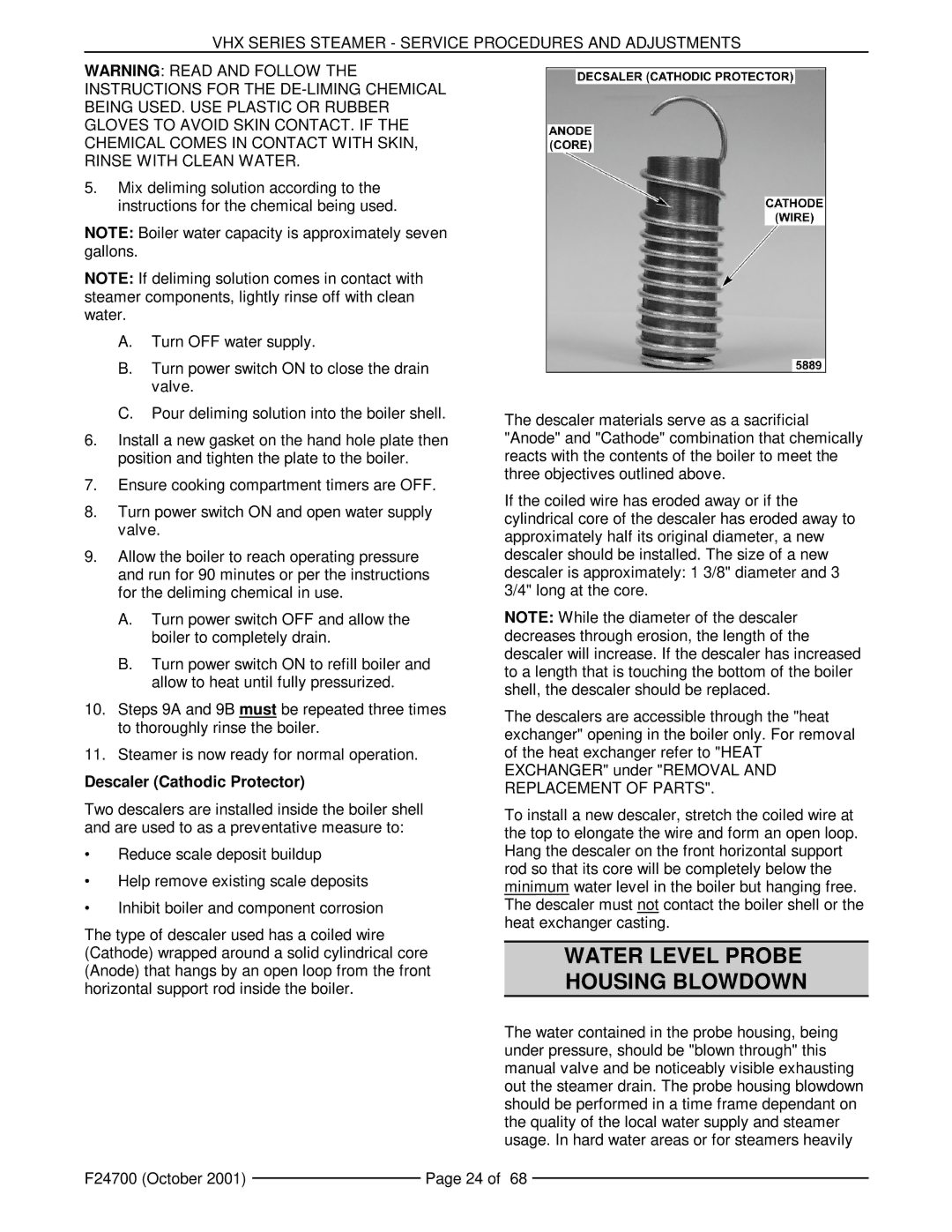

Descaler (Cathodic Protector)

Two descalers are installed inside the boiler shell and are used to as a preventative measure to:

•Reduce scale deposit buildup

•Help remove existing scale deposits

•Inhibit boiler and component corrosion

The type of descaler used has a coiled wire (Cathode) wrapped around a solid cylindrical core (Anode) that hangs by an open loop from the front horizontal support rod inside the boiler.

The descaler materials serve as a sacrificial "Anode" and "Cathode" combination that chemically reacts with the contents of the boiler to meet the three objectives outlined above.

If the coiled wire has eroded away or if the cylindrical core of the descaler has eroded away to approximately half its original diameter, a new descaler should be installed. The size of a new descaler is approximately: 1 3/8" diameter and 3 3/4" long at the core.

NOTE: While the diameter of the descaler decreases through erosion, the length of the descaler will increase. If the descaler has increased to a length that is touching the bottom of the boiler shell, the descaler should be replaced.

The descalers are accessible through the "heat exchanger" opening in the boiler only. For removal of the heat exchanger refer to "HEAT EXCHANGER" under "REMOVAL AND REPLACEMENT OF PARTS".

To install a new descaler, stretch the coiled wire at the top to elongate the wire and form an open loop. Hang the descaler on the front horizontal support rod so that its core will be completely below the minimum water level in the boiler but hanging free. The descaler must not contact the boiler shell or the heat exchanger casting.

WATER LEVEL PROBE

HOUSING BLOWDOWN

The water contained in the probe housing, being under pressure, should be "blown through" this manual valve and be noticeably visible exhausting out the steamer drain. The probe housing blowdown should be performed in a time frame dependant on the quality of the local water supply and steamer usage. In hard water areas or for steamers heavily

F24700 (October 2001) |

| Page 24 of 68 |

|