Piping

6.0PIPING

Refer to

6.1European Union Fluorinated Greenhouse Gas Requirements

Stationary air conditioning, refrigeration, heat pump equipment and stationary fire protection sys- tems in the European Community market and operating with fluorinated greenhouse gases

The

Refer to the full regulation for additional details.

6.2System Connection Configuration

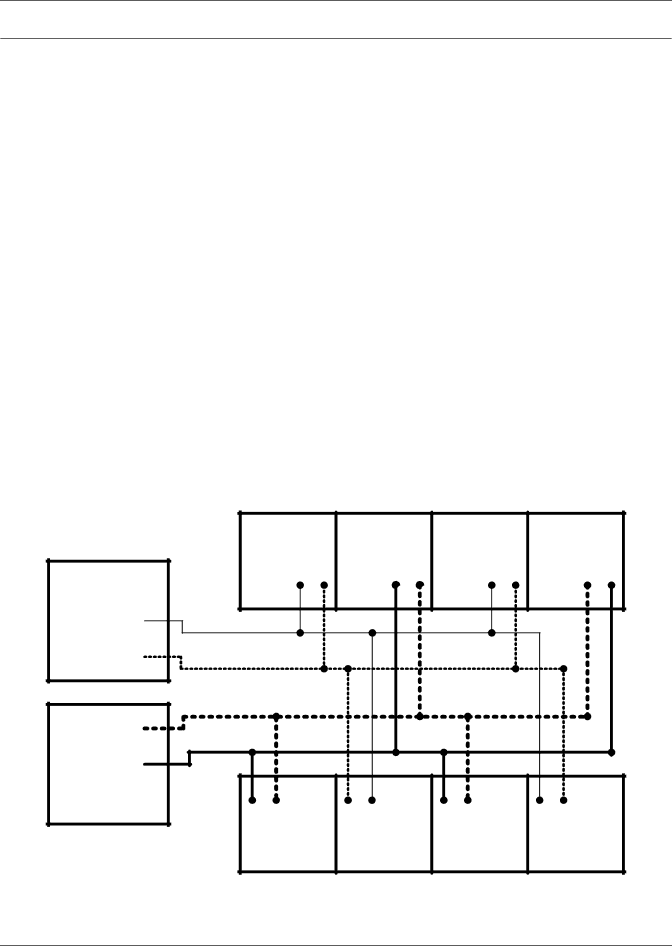

If possible, connect the Liebert XDR modules to Liebert XDPs or Liebert XDCs in an interlaced configuration (see Figure 12). In an interlaced configuration, half the cooling modules in an aisle are connected to one Liebert XDP or Liebert XDC and the other half in that aisle are connected to another Liebert XDP or Liebert XDC. Interlacing the connection piping will keep half the Liebert XDR modules operating and maintain cooling in the conditioned space should one of the Liebert XDP or Liebert XDC units fail.

However, if this is not possible, connect the Liebert XDR modules in a

Figure 12 Typical Liebert XDR piping—interlaced connections

TOP VIEW

DRAWING IS |

|

|

|

|

NOT TO SCALE | Liebert | Liebert | Liebert | Liebert |

| XDR A | XDR B | XDR A | XDR B |

Liebert XDP/ |

|

|

|

|

Liebert XDC A |

|

|

|

|

Supply |

|

|

|

|

Return |

|

|

|

|

Return |

|

|

|

|

Supply |

|

|

|

|

Liebert XDP/

Liebert XDC B

NOTE: Line size does NOT indicate pipe size difference .

Liebert

XDR B

Liebert

XDR A

Liebert

XDR B

Liebert

XDR A

14