Selection

!WARNING

1.This product is intended to be used for the general FA devices.

If other applications (especially the ones indicated in 4 on page 2) are used, please contact SMC before the use.

2.Use under specified voltage and temperature.

Voltage out of specification may cause malfunction, breakage, electric shock and fire.

3. Use clean compressed air for fluid.

Do not use inflammable or explosive gas for fluid. It may cause fire or explosion. When other fluid except compressed air is used, please contact SMC service representative.

4. This product doesn’t incorporate

Do not use this product in the place where dust explosion might be triggered or inflammable or explosive gas is present. It may cause fire.

!CAUTION

1.This product has not been washed.

When bringing into clean room. Use after confirming its purification level after flushing.

Installation

!WARNING

1.Get required space for maintenance, wiring and piping at installation.

Install connector and

Forcible installation and elimination may cause malfunction, broken wire, fire and air leakage. Minimum bending radius: Power supply cable・・・・・・・・・・・・・35mm

Sensor cable・・・・・・・・・・・・・・・・・・・25 mm

(Note: Here is allowable bending radius when fixing wiring at 20oC. If bending cable at lower temperature, it may apply forcible force to connector even with minimum bending radius or more.)

See instruction or catalog for minimum bending radius fo tube.

2. Install on the plane face.

Forcible force may apply to frame or case due to concave and convex or deformed mounting face and large level gap, and it may cause breakage or operation failure. Also, dropping or strong impact may cause operation failure or accident.

3. Do not use in the place where subject to noise (electromagnetic wave, surge etc.)

It may cause a malfunction, or deteriorate or damage internal elements. Take measures to prevent noise source and avoid lines from touching and mixing each other.

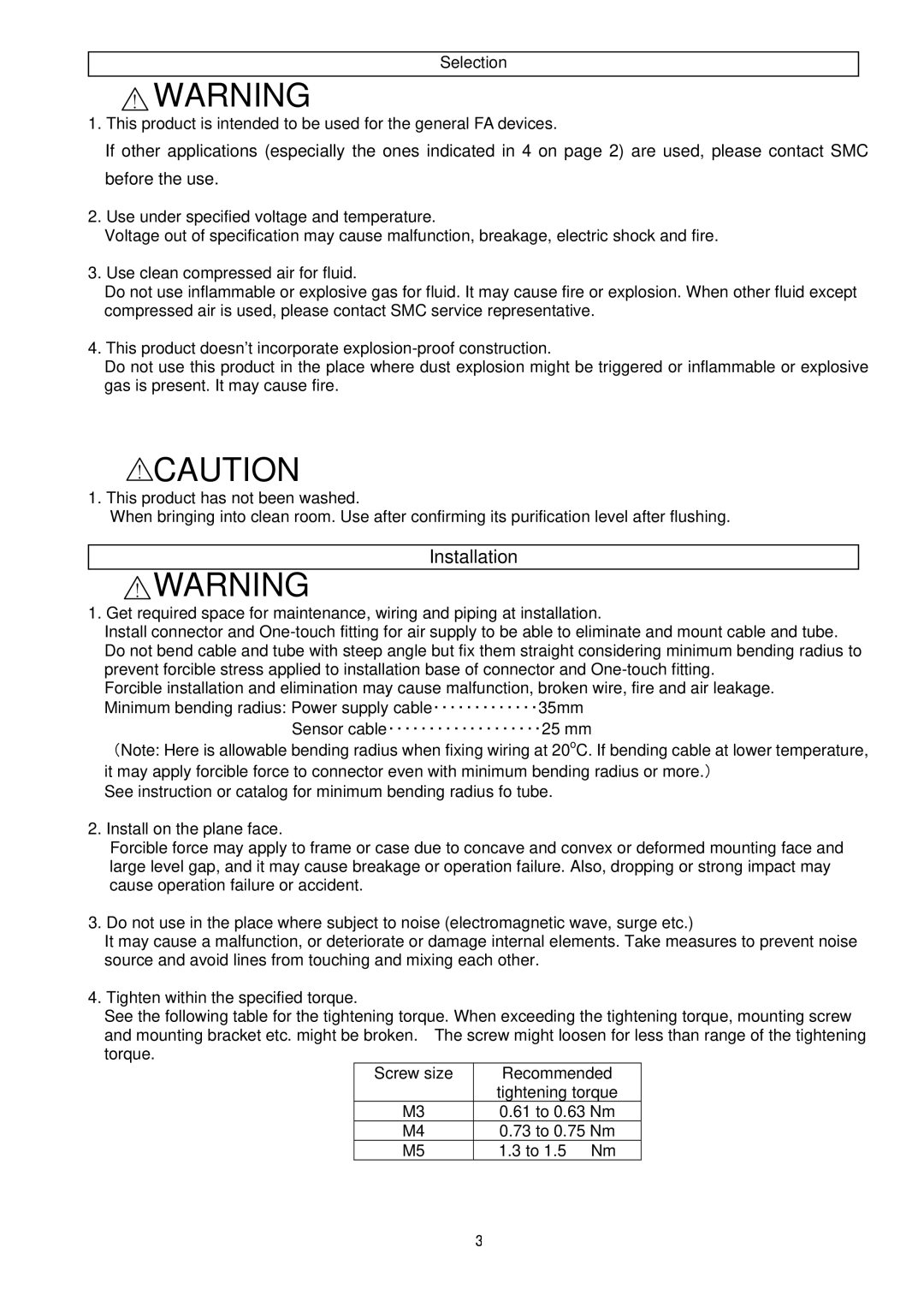

4. Tighten within the specified torque.

See the following table for the tightening torque. When exceeding the tightening torque, mounting screw and mounting bracket etc. might be broken. The screw might loosen for less than range of the tightening torque.

Screw size | Recommended |

| tightening torque |

M3 | 0.61 to 0.63 Nm |

M4 | 0.73 to 0.75 Nm |

M5 | 1.3 to 1.5 Nm |

3

![Sierra Monitor Corporation IZS31 operation manual .Specifications, .Ionizer, [Electrode cartridge quantity and weight]](/prints/sierra-monitor-corporation-izs31/1052224/25.1080/specifications-ionizer.1080.webp)