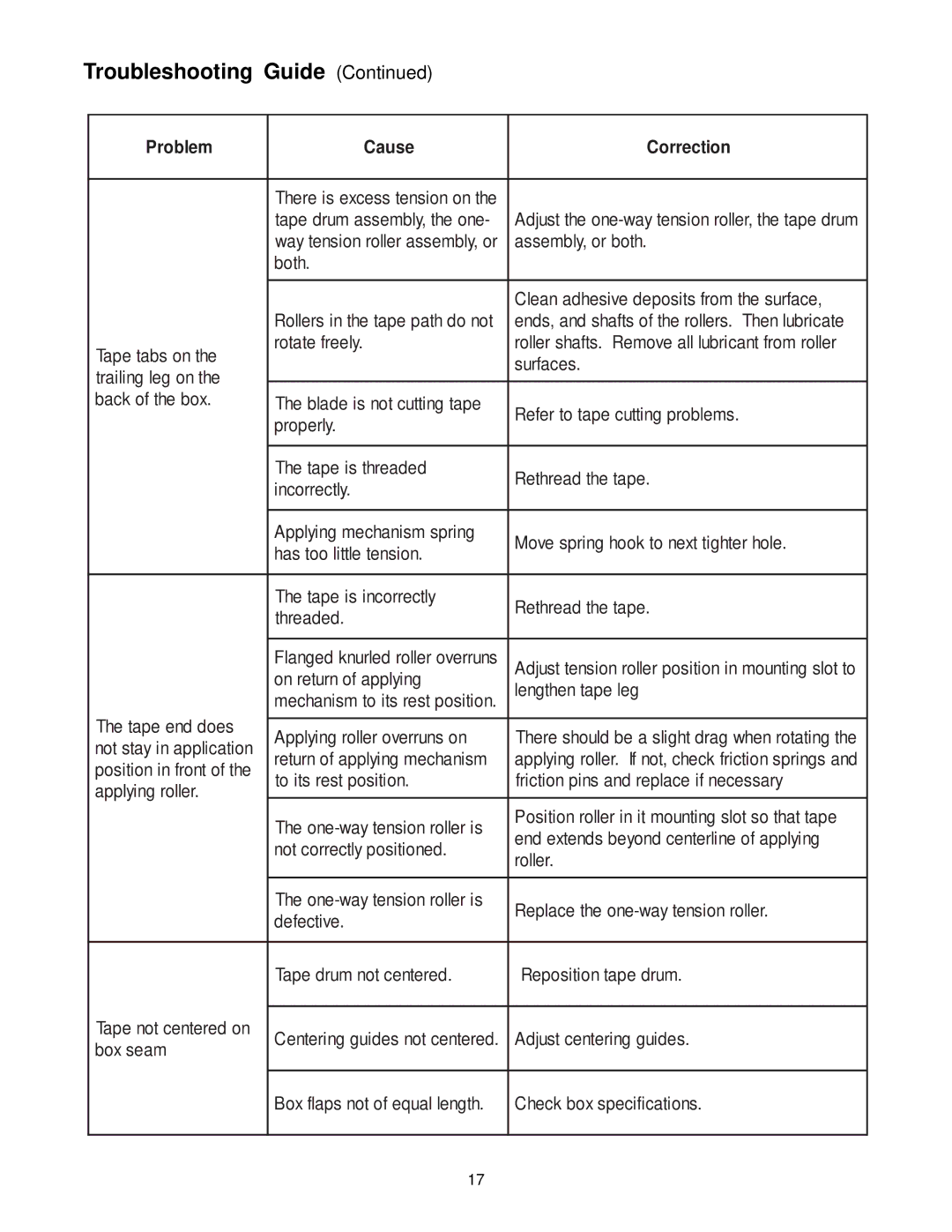

Troubleshooting Guide (Continued)

Problem | Cause | Correction | |

|

|

| |

| There is excess tension on the |

| |

| tape drum assembly, the one- | Adjust the | |

| way tension roller assembly, or | assembly, or both. | |

| both. |

| |

|

|

| |

|

| Clean adhesive deposits from the surface, | |

| Rollers in the tape path do not | ends, and shafts of the rollers. Then lubricate | |

Tape tabs on the | rotate freely. | roller shafts. Remove all lubricant from roller | |

| surfaces. | ||

trailing leg on the |

| ||

|

| ||

|

| ||

back of the box. | The blade is not cutting tape | Refer to tape cutting problems. | |

| properly. | ||

|

| ||

|

|

| |

| The tape is threaded | Rethread the tape. | |

| incorrectly. | ||

|

| ||

|

|

| |

| Applying mechanism spring | Move spring hook to next tighter hole. | |

| has too little tension. | ||

|

| ||

|

|

| |

| The tape is incorrectly | Rethread the tape. | |

| threaded. | ||

|

| ||

|

|

| |

| Flanged knurled roller overruns | Adjust tension roller position in mounting slot to | |

| on return of applying | lengthen tape leg | |

| mechanism to its rest position. | ||

The tape end does |

|

| |

Applying roller overruns on | There should be a slight drag when rotating the | ||

not stay in application | |||

return of applying mechanism | applying roller. If not, check friction springs and | ||

position in front of the | |||

to its rest position. | friction pins and replace if necessary | ||

applying roller. | |||

|

| ||

| The | Position roller in it mounting slot so that tape | |

| end extends beyond centerline of applying | ||

| not correctly positioned. | ||

| roller. | ||

|

| ||

|

|

| |

| The | Replace the | |

| defective. | ||

|

| ||

|

|

| |

| Tape drum not centered. | Reposition tape drum. | |

Tape not centered on |

|

| |

Centering guides not centered. | Adjust centering guides. | ||

box seam | |||

|

| ||

|

|

| |

| Box flaps not of equal length. | Check box specifications. | |

|

|

|

17