Installation and Setup (Continued)

MACHINE BED HEIGHT

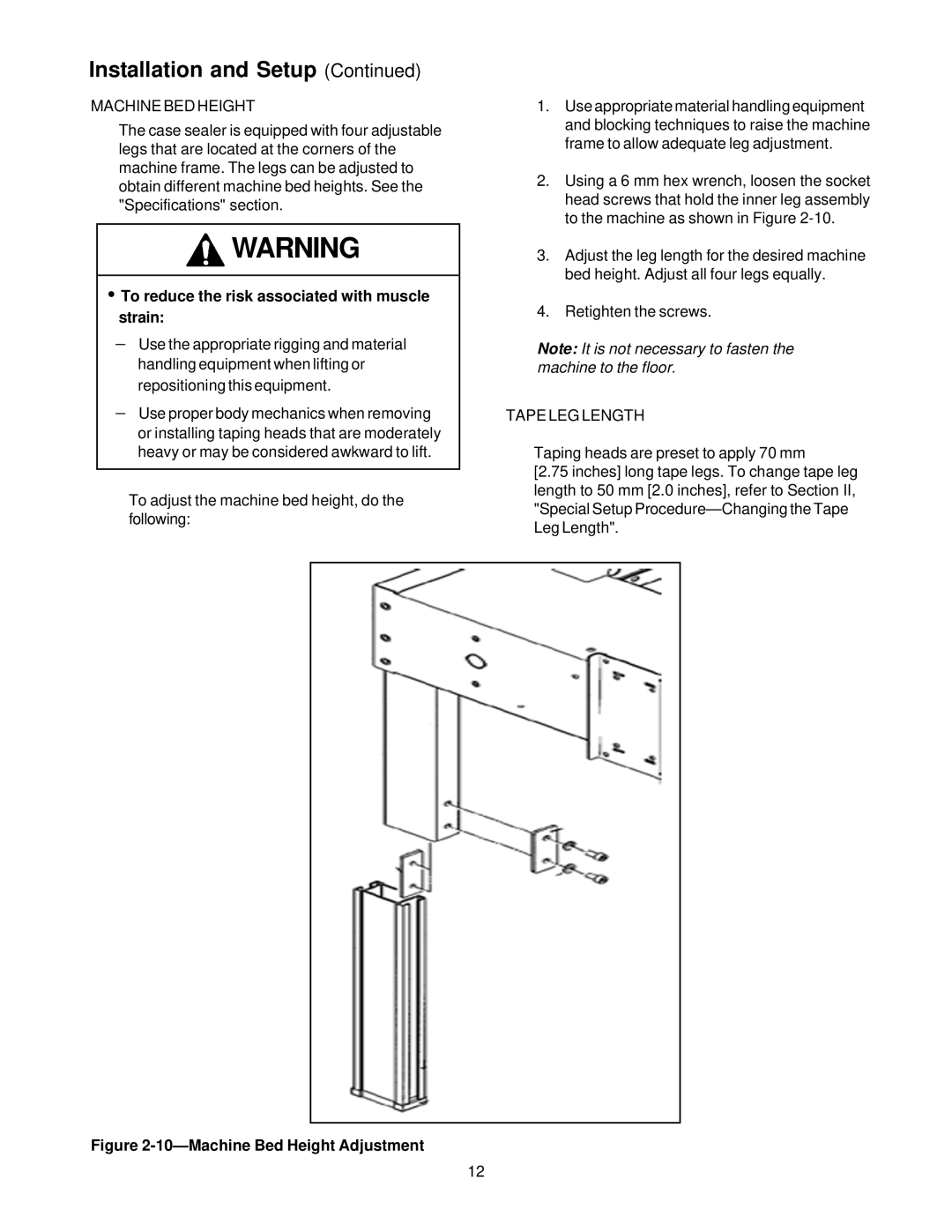

The case sealer is equipped with four adjustable legs that are located at the corners of the machine frame. The legs can be adjusted to obtain different machine bed heights. See the "Specifications" section.

![]() WARNING

WARNING

•To reduce the risk associated with muscle strain:

−Use the appropriate rigging and material handling equipment when lifting or repositioning this equipment.

−Use proper body mechanics when removing or installing taping heads that are moderately heavy or may be considered awkward to lift.

To adjust the machine bed height, do the following:

1.Use appropriate material handling equipment and blocking techniques to raise the machine frame to allow adequate leg adjustment.

2.Using a 6 mm hex wrench, loosen the socket head screws that hold the inner leg assembly to the machine as shown in Figure

3.Adjust the leg length for the desired machine bed height. Adjust all four legs equally.

4.Retighten the screws.

Note: It is not necessary to fasten the machine to the floor.

TAPE LEG LENGTH

Taping heads are preset to apply 70 mm

[2.75 inches] long tape legs. To change tape leg length to 50 mm [2.0 inches], refer to Section II, "Special Setup

Figure 2-10—Machine Bed Height Adjustment

12