Operation (Continued)

For boxes which are fully packed with products that support the top flaps, the adjustment of this regulator is not critical since the boxes can support the pressure of the upper frame (drive belts) at a wide range of regulator settings. However, if

Note: A precision regulator is used to balance the top drive assembly. Due to the self relieving feature of this regulator a small amount of air will continually vent to the atmosphere. This is normal and amounts to approximately 3 liter/min [0.1 SCFM ].

Main Air Pressure Gauge (Figure

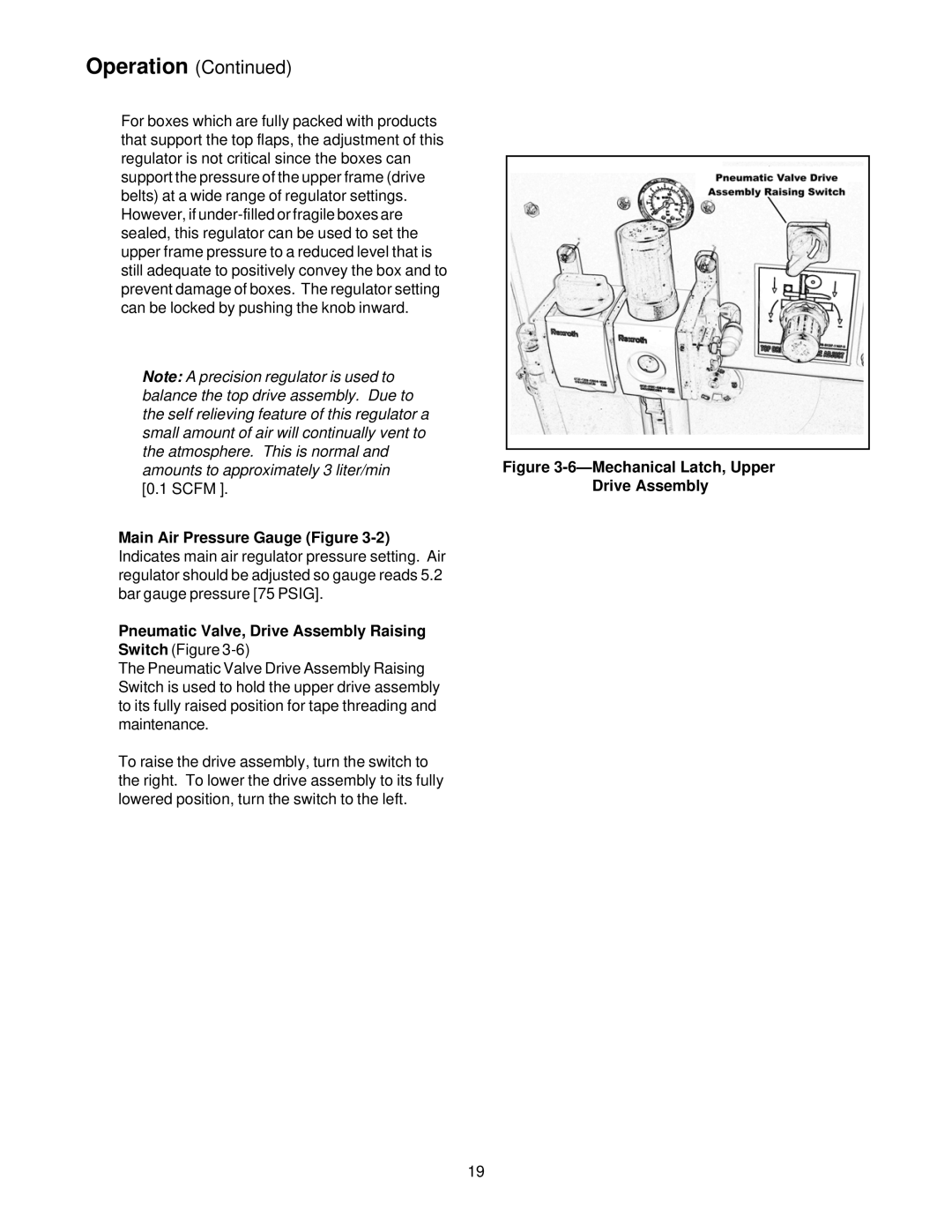

Pneumatic Valve, Drive Assembly Raising

Switch (Figure

The Pneumatic Valve Drive Assembly Raising Switch is used to hold the upper drive assembly to its fully raised position for tape threading and maintenance.

To raise the drive assembly, turn the switch to the right. To lower the drive assembly to its fully lowered position, turn the switch to the left.

Figure 3-6—Mechanical Latch, Upper Drive Assembly

19