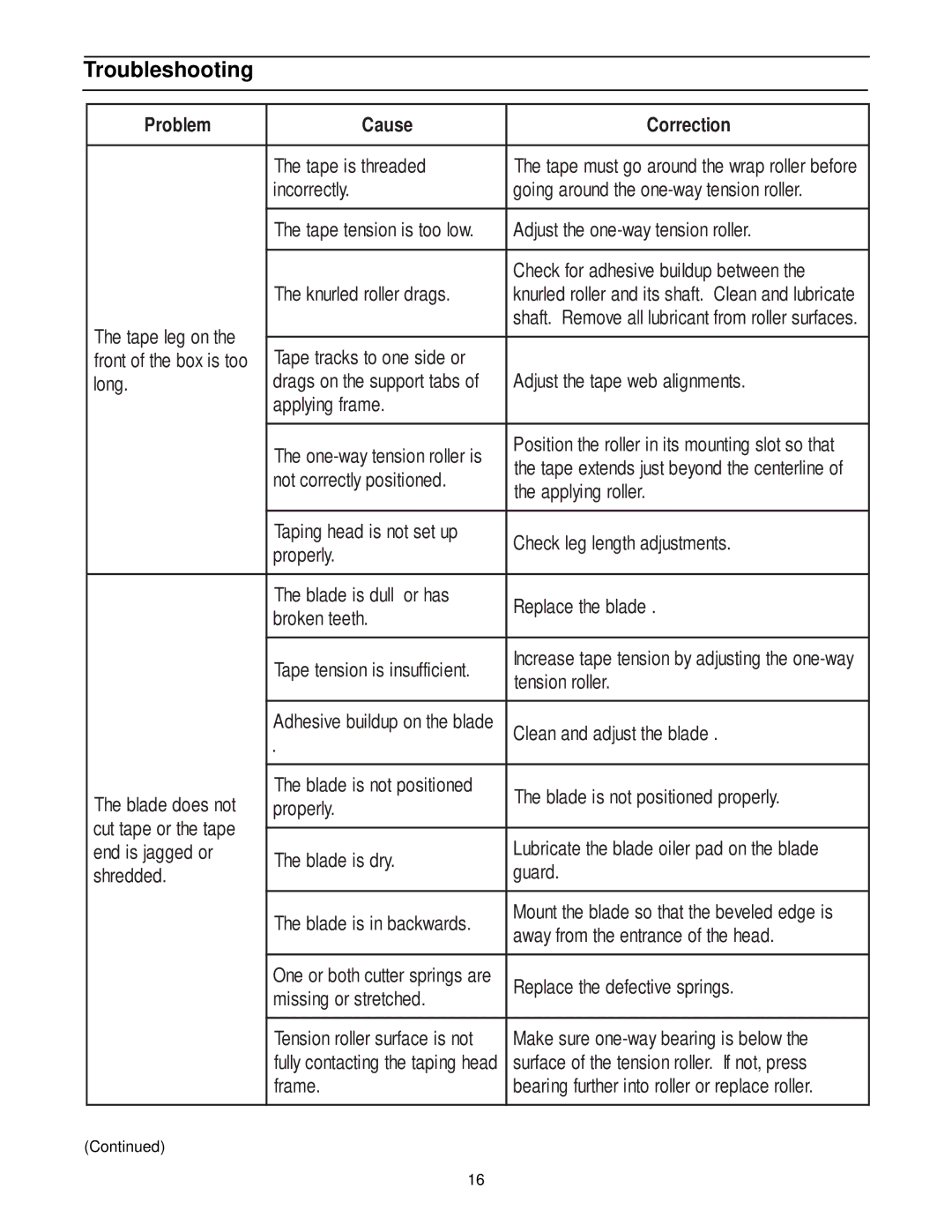

Troubleshooting

Problem | Cause | Correction | |

|

|

| |

| The tape is threaded | The tape must go around the wrap roller before | |

| incorrectly. | going around the | |

|

|

| |

| The tape tension is too low. | Adjust the | |

|

|

| |

|

| Check for adhesive buildup between the | |

| The knurled roller drags. | knurled roller and its shaft. Clean and lubricate | |

The tape leg on the |

| shaft. Remove all lubricant from roller surfaces. | |

|

| ||

Tape tracks to one side or |

| ||

front of the box is too | Adjust the tape web alignments. | ||

long. | drags on the support tabs of | ||

| applying frame. |

| |

|

|

| |

| The | Position the roller in its mounting slot so that | |

| the tape extends just beyond the centerline of | ||

| not correctly positioned. | ||

| the applying roller. | ||

|

| ||

|

|

| |

| Taping head is not set up | Check leg length adjustments. | |

| properly. | ||

|

| ||

|

|

| |

| The blade is dull or has | Replace the blade . | |

| broken teeth. | ||

|

| ||

|

|

| |

| Tape tension is insufficient. | Increase tape tension by adjusting the | |

| tension roller. | ||

|

| ||

|

|

| |

| Adhesive buildup on the blade | Clean and adjust the blade . | |

| . |

| |

The blade does not | The blade is not positioned | The blade is not positioned properly. | |

properly. | |||

| |||

cut tape or the tape |

|

| |

| Lubricate the blade oiler pad on the blade | ||

end is jagged or | The blade is dry. | ||

shredded. | guard. | ||

| |||

| The blade is in backwards. | Mount the blade so that the beveled edge is | |

| away from the entrance of the head. | ||

|

| ||

|

|

| |

| One or both cutter springs are | Replace the defective springs. | |

| missing or stretched. | ||

|

| ||

|

|

| |

| Tension roller surface is not | Make sure | |

| fully contacting the taping head | surface of the tension roller. If not, press | |

| frame. | bearing further into roller or replace roller. | |

|

|

|

(Continued)

16