Adjustments (Continued)

![]() WARNING

WARNING

•To reduce the risk associated with shear, pinch, and entanglement hazards:

−Turn air and electrical supplies off on associated equipment before performing any adjustments, maintenance, or servicing the machine or taping heads.

−Never attempt to work on the taping head or load tape while the box drive system is running.

Tape Leg Length

![]() WARNING

WARNING

•To reduce the risk associated with sharp blade hazards:

−Keep hands and fingers away from tape cutoff knives under orange blade guards. The blades are extremely sharp.

LEADING TAPE LEG LENGTH ADJUSTMENT

The

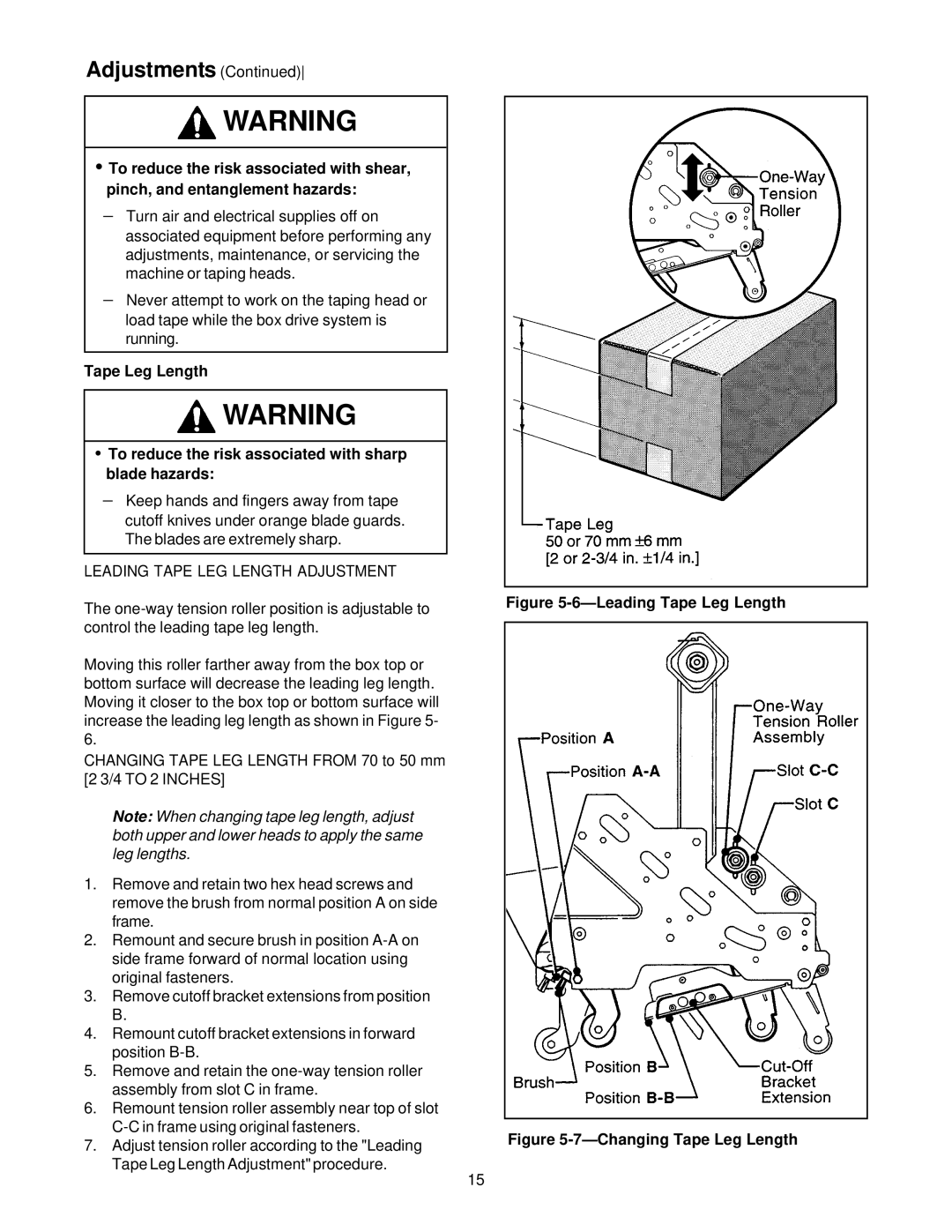

Moving this roller farther away from the box top or bottom surface will decrease the leading leg length. Moving it closer to the box top or bottom surface will increase the leading leg length as shown in Figure 5- 6.

CHANGING TAPE LEG LENGTH FROM 70 to 50 mm [2 3/4 TO 2 INCHES]

Note: When changing tape leg length, adjust both upper and lower heads to apply the same leg lengths.

1.Remove and retain two hex head screws and remove the brush from normal position A on side frame.

2.Remount and secure brush in position

3.Remove cutoff bracket extensions from position B.

4.Remount cutoff bracket extensions in forward position

5.Remove and retain the

6.Remount tension roller assembly near top of slot

7.Adjust tension roller according to the "Leading Tape Leg Length Adjustment" procedure.

Figure 5-6—Leading Tape Leg Length

Figure 5-7—Changing Tape Leg Length

15