Chapter 3 Calibration Procedures

Automating Calibration Procedures

Automating Calibration Procedures

You can automate the complete verification procedures outlined in this chapter if you have access to programmable test equipment. You can program the instrument configurations specified for each test over the remote interface. You can then enter readback verification data into a test program and compare the results to the appropriate test limit values.

You can also enter calibration constants from the remote interface. Remote operation is similar to the local

For further details on programming the power supply, see chapters 3 and 4 in the Agilent E3632A User's Guide.

Recommended Test Equipment

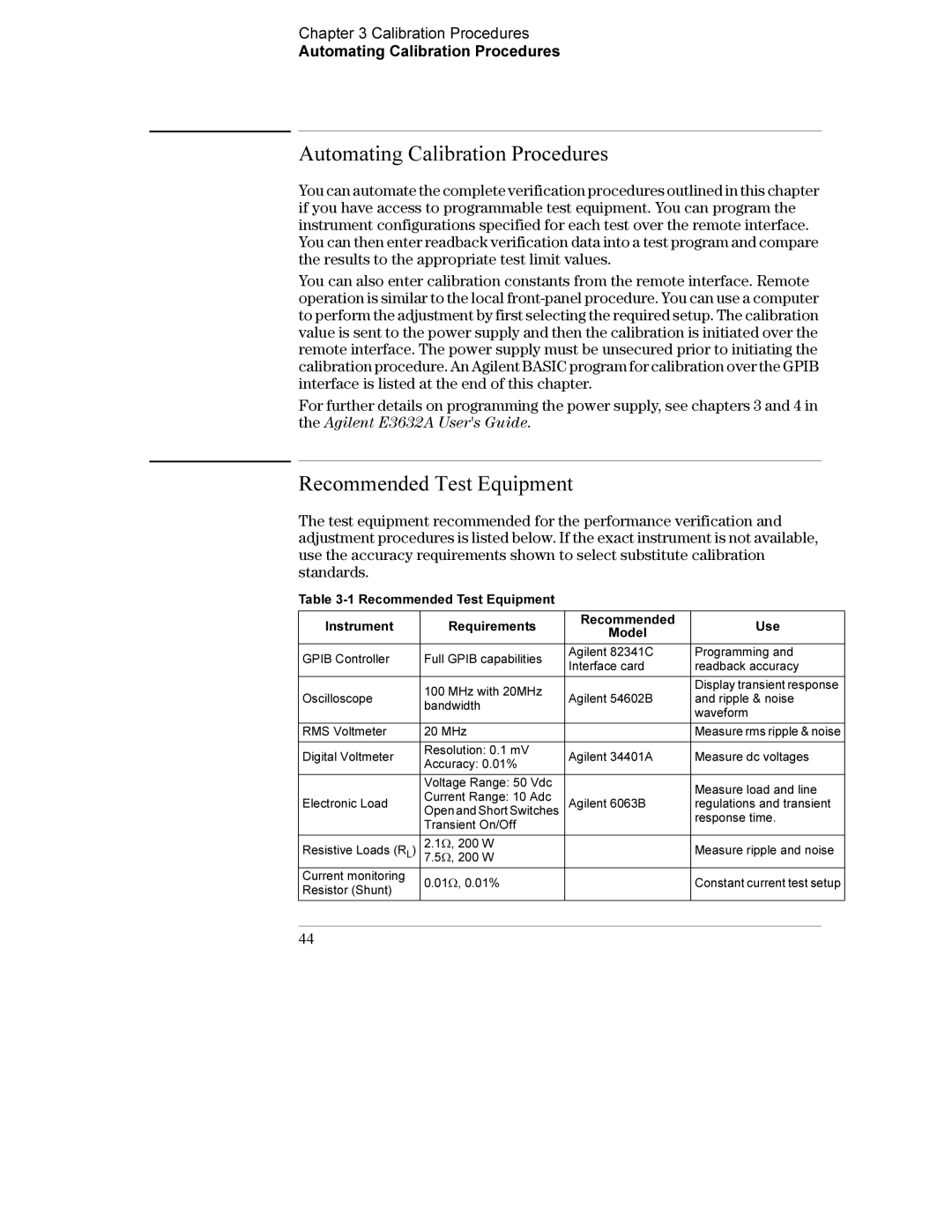

The test equipment recommended for the performance verification and adjustment procedures is listed below. If the exact instrument is not available, use the accuracy requirements shown to select substitute calibration standards.

Table

Instrument | Requirements | Recommended | Use | |

Model | ||||

|

|

| ||

|

|

|

| |

GPIB Controller | Full GPIB capabilities | Agilent 82341C | Programming and | |

Interface card | readback accuracy | |||

|

| |||

|

|

|

| |

| 100 MHz with 20MHz |

| Display transient response | |

Oscilloscope | Agilent 54602B | and ripple & noise | ||

bandwidth | ||||

|

| waveform | ||

|

|

| ||

|

|

|

| |

RMS Voltmeter | 20 MHz |

| Measure rms ripple & noise | |

|

|

|

| |

Digital Voltmeter | Resolution: 0.1 mV | Agilent 34401A | Measure dc voltages | |

Accuracy: 0.01% | ||||

|

|

| ||

|

|

|

| |

| Voltage Range: 50 Vdc |

| Measure load and line | |

| Current Range: 10 Adc |

| ||

Electronic Load | Agilent 6063B | regulations and transient | ||

Open and Short Switches | ||||

| Transient On/Off |

| response time. | |

|

|

| ||

|

|

|

| |

Resistive Loads (RL) | 2.19, 200 W |

| Measure ripple and noise | |

7.59, 200 W |

| |||

|

|

|

| |

Current monitoring | 0.019, 0.01% |

| Constant current test setup | |

Resistor (Shunt) |

| |||

|

|

| ||

|

|

|

|

44