Chapter 3 Calibration Procedures

Measurement Techniques

General Measurement Techniques

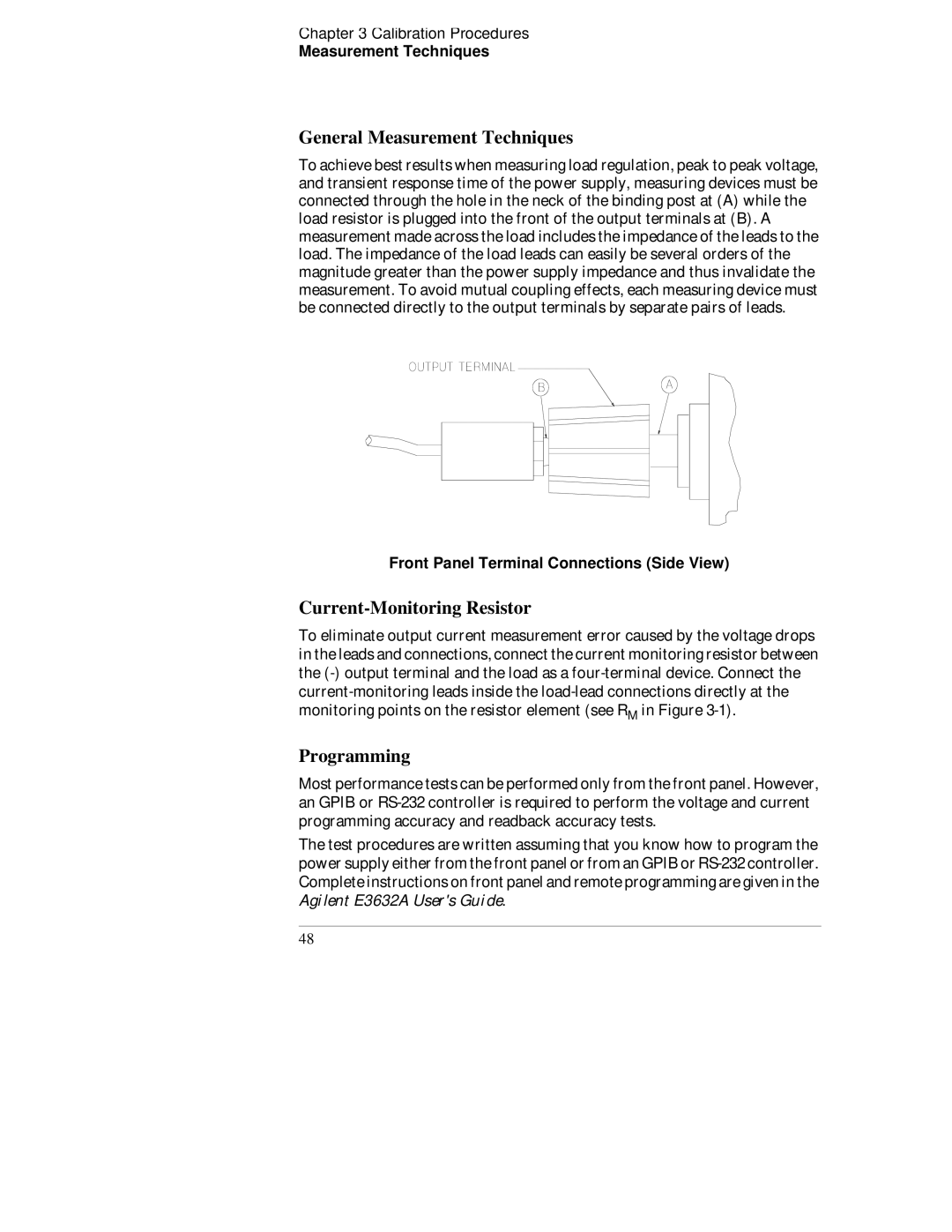

To achieve best results when measuring load regulation, peak to peak voltage, and transient response time of the power supply, measuring devices must be connected through the hole in the neck of the binding post at (A) while the load resistor is plugged into the front of the output terminals at (B). A measurement made across the load includes the impedance of the leads to the load. The impedance of the load leads can easily be several orders of the magnitude greater than the power supply impedance and thus invalidate the measurement. To avoid mutual coupling effects, each measuring device must be connected directly to the output terminals by separate pairs of leads.

Front Panel Terminal Connections (Side View)

Current-Monitoring Resistor

To eliminate output current measurement error caused by the voltage drops in the leads and connections, connect the current monitoring resistor between the

Programming

Most performance tests can be performed only from the front panel. However, an GPIB or

The test procedures are written assuming that you know how to program the power supply either from the front panel or from an GPIB or

48