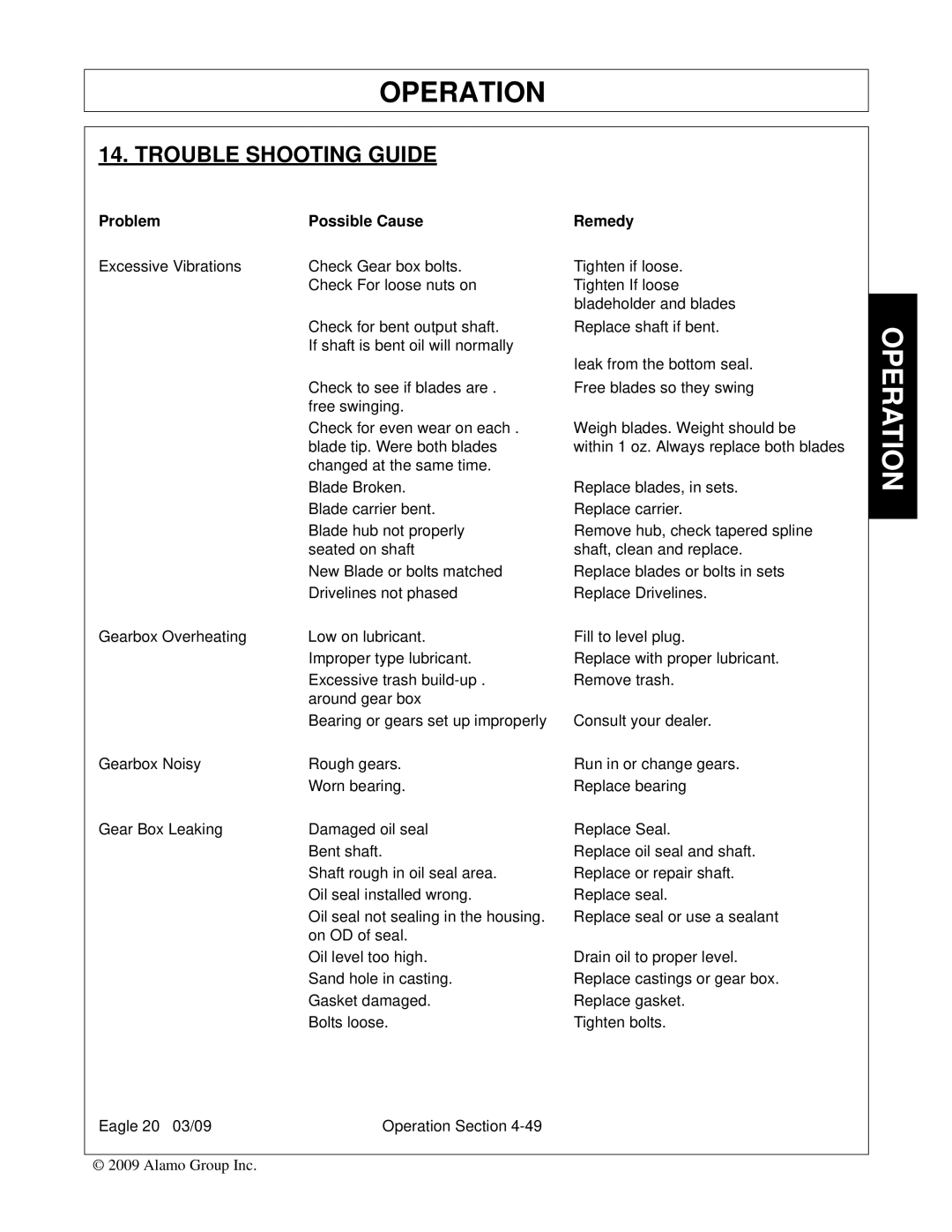

OPERATION

14. TROUBLE SHOOTING GUIDE

Problem | Possible Cause |

Excessive Vibrations | Check Gear box bolts. |

| Check For loose nuts on |

| Check for bent output shaft. |

| If shaft is bent oil will normally |

| Check to see if blades are . |

| free swinging. |

| Check for even wear on each . |

| blade tip. Were both blades |

| changed at the same time. |

| Blade Broken. |

| Blade carrier bent. |

| Blade hub not properly |

| seated on shaft |

| New Blade or bolts matched |

| Drivelines not phased |

Gearbox Overheating | Low on lubricant. |

| Improper type lubricant. |

| Excessive trash |

| around gear box |

| Bearing or gears set up improperly |

Gearbox Noisy | Rough gears. |

| Worn bearing. |

Gear Box Leaking | Damaged oil seal |

| Bent shaft. |

| Shaft rough in oil seal area. |

| Oil seal installed wrong. |

| Oil seal not sealing in the housing. |

| on OD of seal. |

| Oil level too high. |

| Sand hole in casting. |

| Gasket damaged. |

| Bolts loose. |

Remedy

Tighten if loose. Tighten If loose bladeholder and blades

Replace shaft if bent.

leak from the bottom seal. Free blades so they swing

Weigh blades. Weight should be

within 1 oz. Always replace both blades

Replace blades, in sets. Replace carrier.

Remove hub, check tapered spline shaft, clean and replace.

Replace blades or bolts in sets Replace Drivelines.

Fill to level plug.

Replace with proper lubricant. Remove trash.

Consult your dealer.

Run in or change gears.

Replace bearing

Replace Seal.

Replace oil seal and shaft. Replace or repair shaft. Replace seal.

Replace seal or use a sealant

Drain oil to proper level. Replace castings or gear box. Replace gasket.

Tighten bolts.

OPERATION

Eagle 20 03/09 | Operation Section |

© 2009 Alamo Group Inc.