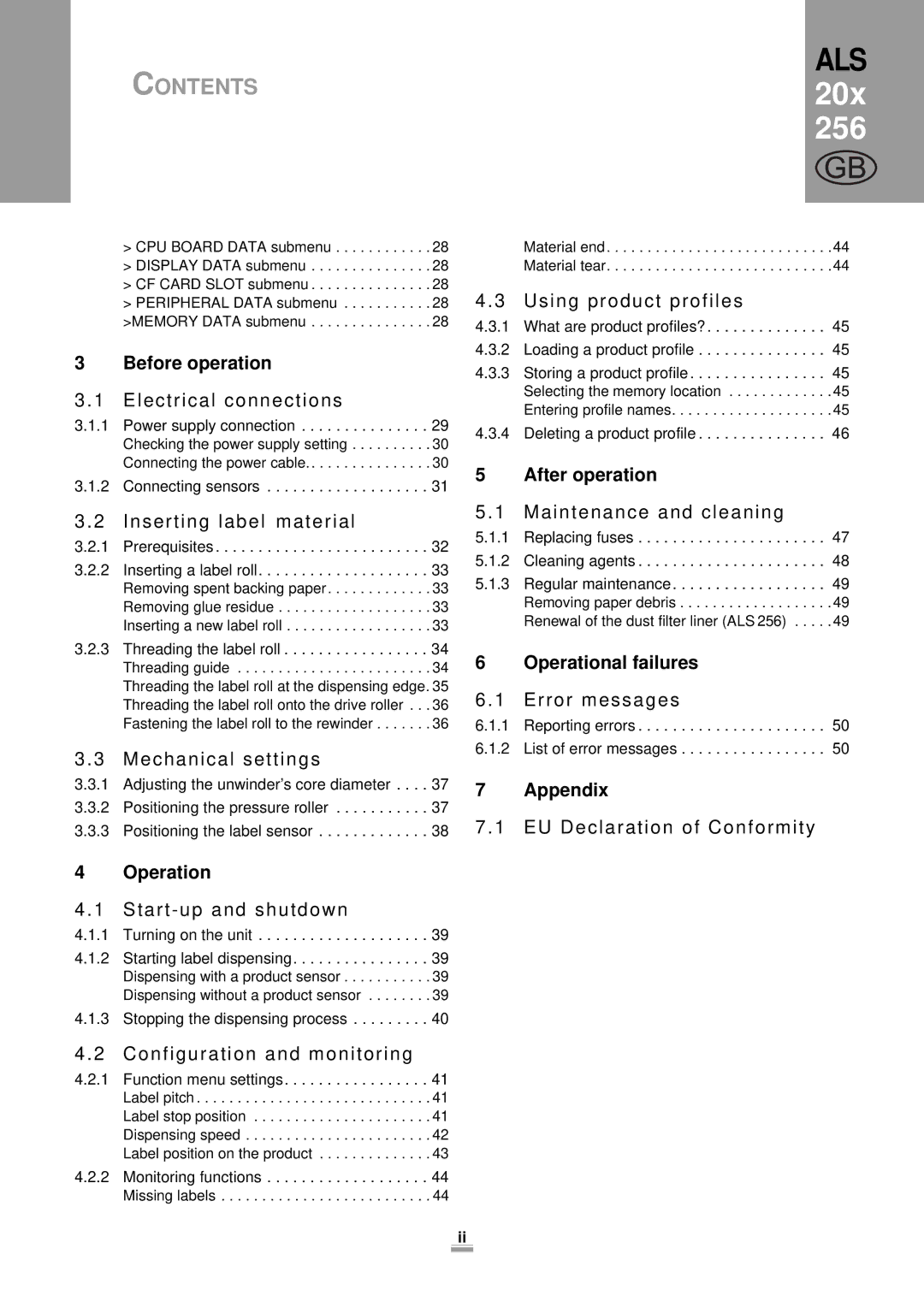

CONTENTS

ALS 20x 256

GB

> CPU BOARD DATA submenu . . . . . . . . . . . . 28 > DISPLAY DATA submenu . . . . . . . . . . . . . . . 28 > CF CARD SLOT submenu . . . . . . . . . . . . . . . 28 > PERIPHERAL DATA submenu . . . . . . . . . . . 28 >MEMORY DATA submenu . . . . . . . . . . . . . . . 28

3 Before operation

3.1 Electrical connections

3.1.1 Power supply connection . . . . . . . . . . . . . . . 29

Checking the power supply setting . . . . . . . . . . 30 Connecting the power cable.. . . . . . . . . . . . . . . 30

3.1.2 Connecting sensors . . . . . . . . . . . . . . . . . . . 31

Material end. . . . . . . . . . . . . . . . . . . . . . . . . . . .44 Material tear. . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.3 Using product profiles

4.3.1 What are product profiles? . . . . . . . . . . . . . . 45 4.3.2 Loading a product profile . . . . . . . . . . . . . . . 45 4.3.3 Storing a product profile . . . . . . . . . . . . . . . . 45

Selecting the memory location . . . . . . . . . . . . .45 Entering profile names. . . . . . . . . . . . . . . . . . . .45

4.3.4 Deleting a product profile . . . . . . . . . . . . . . . 46

5 After operation

3.2 Inserting label material

3.2.1 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . 32 3.2.2 Inserting a label roll. . . . . . . . . . . . . . . . . . . . 33

Removing spent backing paper. . . . . . . . . . . . . 33 Removing glue residue . . . . . . . . . . . . . . . . . . . 33 Inserting a new label roll . . . . . . . . . . . . . . . . . . 33

3.2.3 Threading the label roll . . . . . . . . . . . . . . . . . 34

Threading guide . . . . . . . . . . . . . . . . . . . . . . . . 34 Threading the label roll at the dispensing edge. 35 Threading the label roll onto the drive roller . . . 36 Fastening the label roll to the rewinder . . . . . . . 36

3.3 Mechanical settings

3.3.1 Adjusting the unwinder’s core diameter . . . . 37 3.3.2 Positioning the pressure roller . . . . . . . . . . . 37 3.3.3 Positioning the label sensor . . . . . . . . . . . . . 38

4 Operation

4.1 Start-up and shutdown

4.1.1 Turning on the unit . . . . . . . . . . . . . . . . . . . . 39 4.1.2 Starting label dispensing. . . . . . . . . . . . . . . . 39

Dispensing with a product sensor . . . . . . . . . . . 39 Dispensing without a product sensor . . . . . . . . 39

4.1.3 Stopping the dispensing process . . . . . . . . . 40

5.1 Maintenance and cleaning

5.1.1 Replacing fuses . . . . . . . . . . . . . . . . . . . . . . 47 5.1.2 Cleaning agents . . . . . . . . . . . . . . . . . . . . . . 48 5.1.3 Regular maintenance . . . . . . . . . . . . . . . . . . 49

Removing paper debris . . . . . . . . . . . . . . . . . . .49 Renewal of the dust filter liner (ALS 256) . . . . .49

6 Operational failures

6.1 Error messages

6.1.1 Reporting errors . . . . . . . . . . . . . . . . . . . . . . 50 6.1.2 List of error messages . . . . . . . . . . . . . . . . . 50

7 Appendix

7.1 EU Declaration of Conformity

4.2 Configuration and monitoring

4.2.1 Function menu settings. . . . . . . . . . . . . . . . . 41

Label pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Label stop position . . . . . . . . . . . . . . . . . . . . . . 41 Dispensing speed . . . . . . . . . . . . . . . . . . . . . . . 42 Label position on the product . . . . . . . . . . . . . . 43

4.2.2 Monitoring functions . . . . . . . . . . . . . . . . . . . 44

Missing labels . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ii