Page 16 | BRADFORD WHITE CORP. |

|

|

|

|

| C |

SYSTEM |

|

RETURN | B |

| A |

PUMP LOCATION FOR

T1

COLD WATER

C

| SYSTEM |

SYSTEM PUMP | SUPPLY |

B

A

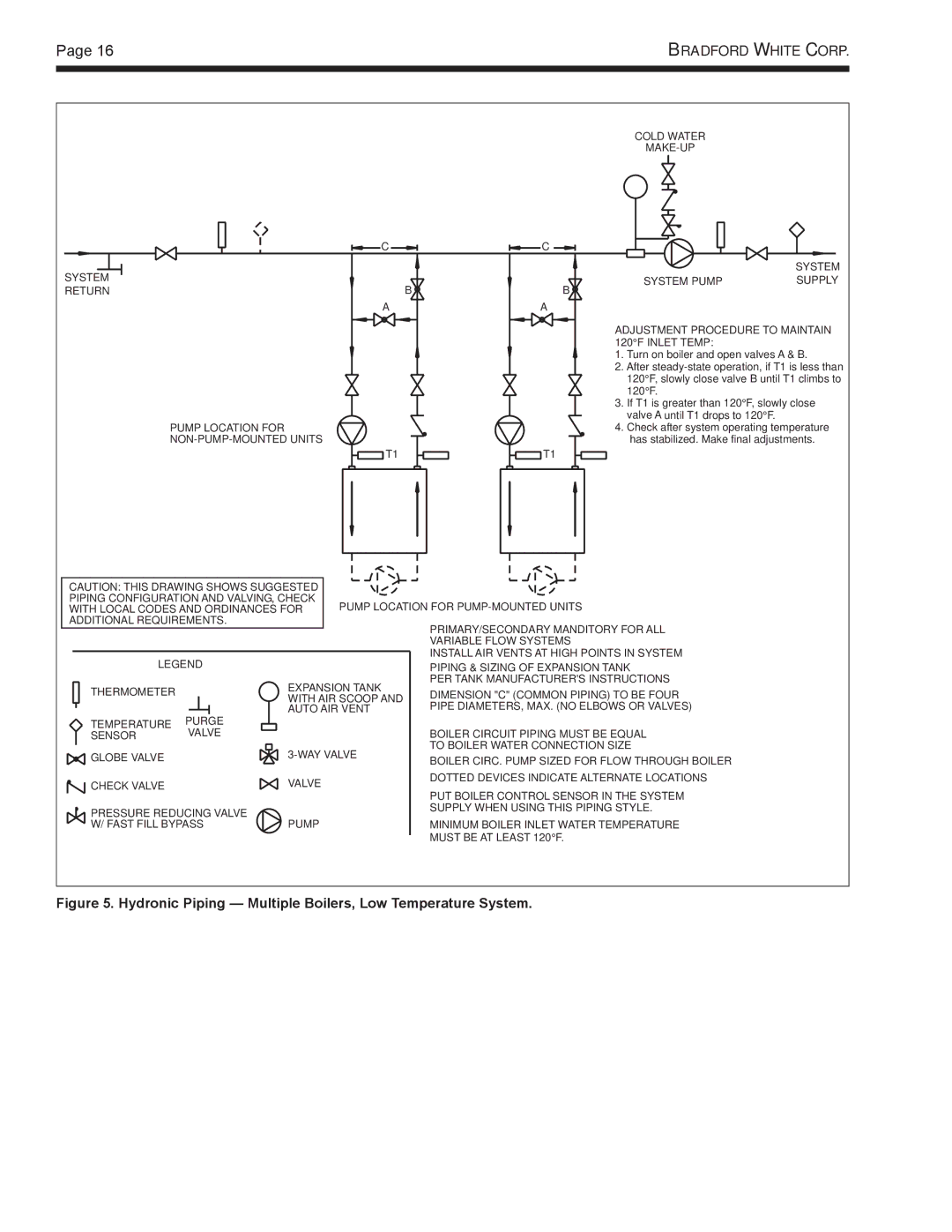

ADJUSTMENT PROCEDURE TO MAINTAIN 120°F INLET TEMP:

1.Turn on boiler and open valves A & B.

2.After

3.If T1 is greater than 120°F, slowly close valve A until T1 drops to 120°F.

4.Check after system operating temperature has stabilized. Make final adjustments.

T1

CAUTION: THIS DRAWING SHOWS SUGGESTED |

|

| ||

PIPING CONFIGURATION AND VALVING, CHECK | PUMP LOCATION FOR | |||

WITH LOCAL CODES AND ORDINANCES FOR | ||||

ADDITIONAL REQUIREMENTS. |

|

| PRIMARY/SECONDARY MANDITORY FOR ALL | |

|

|

|

| |

|

|

|

| VARIABLE FLOW SYSTEMS |

|

|

|

| INSTALL AIR VENTS AT HIGH POINTS IN SYSTEM |

LEGEND |

|

| PIPING & SIZING OF EXPANSION TANK | |

|

|

|

| |

|

| EXPANSION TANK | PER TANK MANUFACTURER'S INSTRUCTIONS | |

THERMOMETER |

| DIMENSION "C" (COMMON PIPING) TO BE FOUR | ||

| WITH AIR SCOOP AND | |||

|

| |||

|

| PIPE DIAMETERS, MAX. (NO ELBOWS OR VALVES) | ||

|

| AUTO AIR VENT | ||

TEMPERATURE | PURGE |

|

|

|

VALVE |

|

| BOILER CIRCUIT PIPING MUST BE EQUAL | |

SENSOR |

|

| ||

|

| TO BOILER WATER CONNECTION SIZE | ||

GLOBE VALVE |

| BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER | ||

|

|

| ||

|

|

|

| |

CHECK VALVE |

| VALVE |

| DOTTED DEVICES INDICATE ALTERNATE LOCATIONS |

|

|

| ||

|

|

| PUT BOILER CONTROL SENSOR IN THE SYSTEM | |

|

|

|

| |

PRESSURE REDUCING VALVE |

|

| SUPPLY WHEN USING THIS PIPING STYLE. | |

|

|

| ||

W/ FAST FILL BYPASS | PUMP |

| MINIMUM BOILER INLET WATER TEMPERATURE | |

|

|

|

| MUST BE AT LEAST 120°F. |