COPPER BRUTE II (500 - 2000) | Page 17 |

|

|

|

|

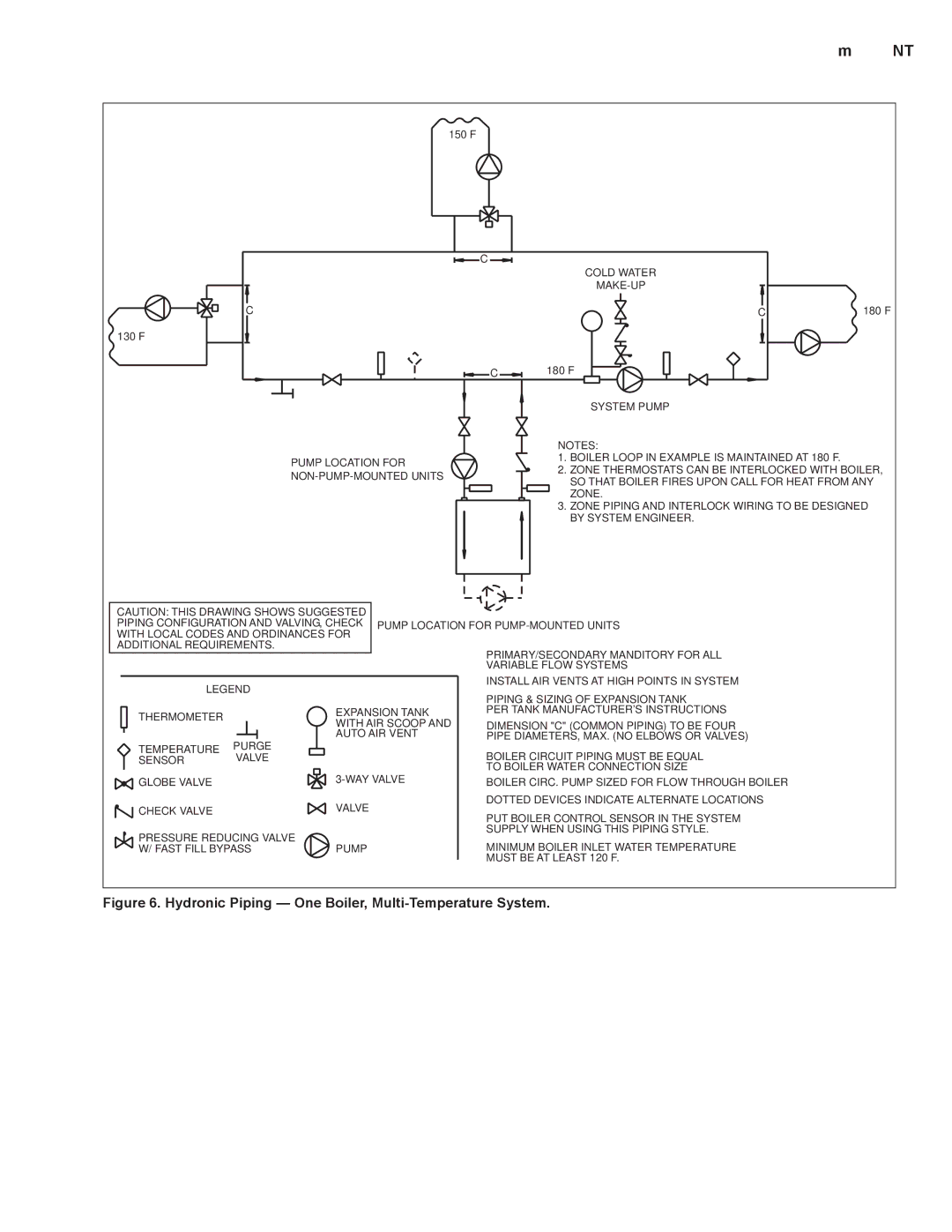

150°F

C

|

|

| COLD WATER |

|

|

|

|

| |

C |

|

| C | 180°F |

130°F |

|

|

|

|

|

| C | 180°F |

|

|

|

|

| |

|

|

| SYSTEM PUMP |

|

|

|

| NOTES: |

|

| PUMP LOCATION FOR |

| 1. BOILER LOOP IN EXAMPLE IS MAINTAINED AT 180°F. |

|

|

| 2. ZONE THERMOSTATS CAN BE INTERLOCKED WITH BOILER, | ||

|

| |||

|

| SO THAT BOILER FIRES UPON CALL FOR HEAT FROM ANY | ||

|

|

| ||

|

|

| ZONE. |

|

|

|

| 3. ZONE PIPING AND INTERLOCK WIRING TO BE DESIGNED | |

|

|

| BY SYSTEM ENGINEER. |

|

CAUTION: THIS DRAWING SHOWS SUGGESTED |

|

| ||

PIPING CONFIGURATION AND VALVING, CHECK | PUMP LOCATION FOR | |||

WITH LOCAL CODES AND ORDINANCES FOR |

|

| ||

ADDITIONAL REQUIREMENTS. |

|

| PRIMARY/SECONDARY MANDITORY FOR ALL | |

|

|

|

| |

|

|

|

| VARIABLE FLOW SYSTEMS |

LEGEND |

|

| INSTALL AIR VENTS AT HIGH POINTS IN SYSTEM | |

|

|

| ||

|

|

|

| PIPING & SIZING OF EXPANSION TANK |

THERMOMETER |

| EXPANSION TANK | PER TANK MANUFACTURER'S INSTRUCTIONS | |

|

| |||

| WITH AIR SCOOP AND | DIMENSION "C" (COMMON PIPING) TO BE FOUR | ||

|

| |||

|

| AUTO AIR VENT | PIPE DIAMETERS, MAX. (NO ELBOWS OR VALVES) | |

| PURGE |

|

| |

TEMPERATURE |

|

|

| |

VALVE |

|

| BOILER CIRCUIT PIPING MUST BE EQUAL | |

SENSOR |

|

| ||

|

|

| TO BOILER WATER CONNECTION SIZE | |

|

|

|

| |

GLOBE VALVE | |

| |

CHECK VALVE | VALVE |

| |

PRESSURE REDUCING VALVE |

|

W/ FAST FILL BYPASS | PUMP |

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

PUT BOILER CONTROL SENSOR IN THE SYSTEM SUPPLY WHEN USING THIS PIPING STYLE.

MINIMUM BOILER INLET WATER TEMPERATURE MUST BE AT LEAST 120°F.