COPPER BRUTE II (500 - 2000) | Page 9 |

|

|

|

|

length allowed is 50 feet (15.2m). Three elbows have been calculated into the

The connection for the intake air pipe is on the filter box. The Copper Brute II appliances may have venting and combustion air ducting attached to the top or the back. They are shipped with the connections at the top. For attaching either or both pipes to the back, the mounting flanges are reversible by removing the mounting screws and orienting the flanges in the desired position. Replace the screws after positioning flanges. Run a bead of silicone around the collar and slide the pipe over the collar. Secure with sheet metal screws.

In addition to air needed for combustion, air shall also be supplied for ventilation, including all air required for comfort and proper working conditions for personnel. The Copper Brute II loses less than 1 percent of its input rating to the room, but other heat sources may be present.

2.2 Venting

2.2.1 Vent Categories

Depending upon desired Copper Brute II venting, it may be considered a Category I or a Category III appliance. In general, a vertical vent system will

be a Category I system. However, in rare instances, a Copper Brute II’s vertical vent system may be considered Category III. In the U.S., the National Fuel Gas Code (ANSI

I vent system, and includes rules and tables to size these vent systems. If the Copper Brute II’s vertical vent system does not satisfy the criteria for Category I venting, it must be vented as a Category III system.

All Copper Brute II vent systems which discharge horizontally (without the use of a power

venter) are considered Category III vent systems.

2.2.2 Category I Vent

When vented as a category I appliance, the

vent system must conform to the National Fuel Gas Code (ANSI

If chimney height is greater than 25 feet, or

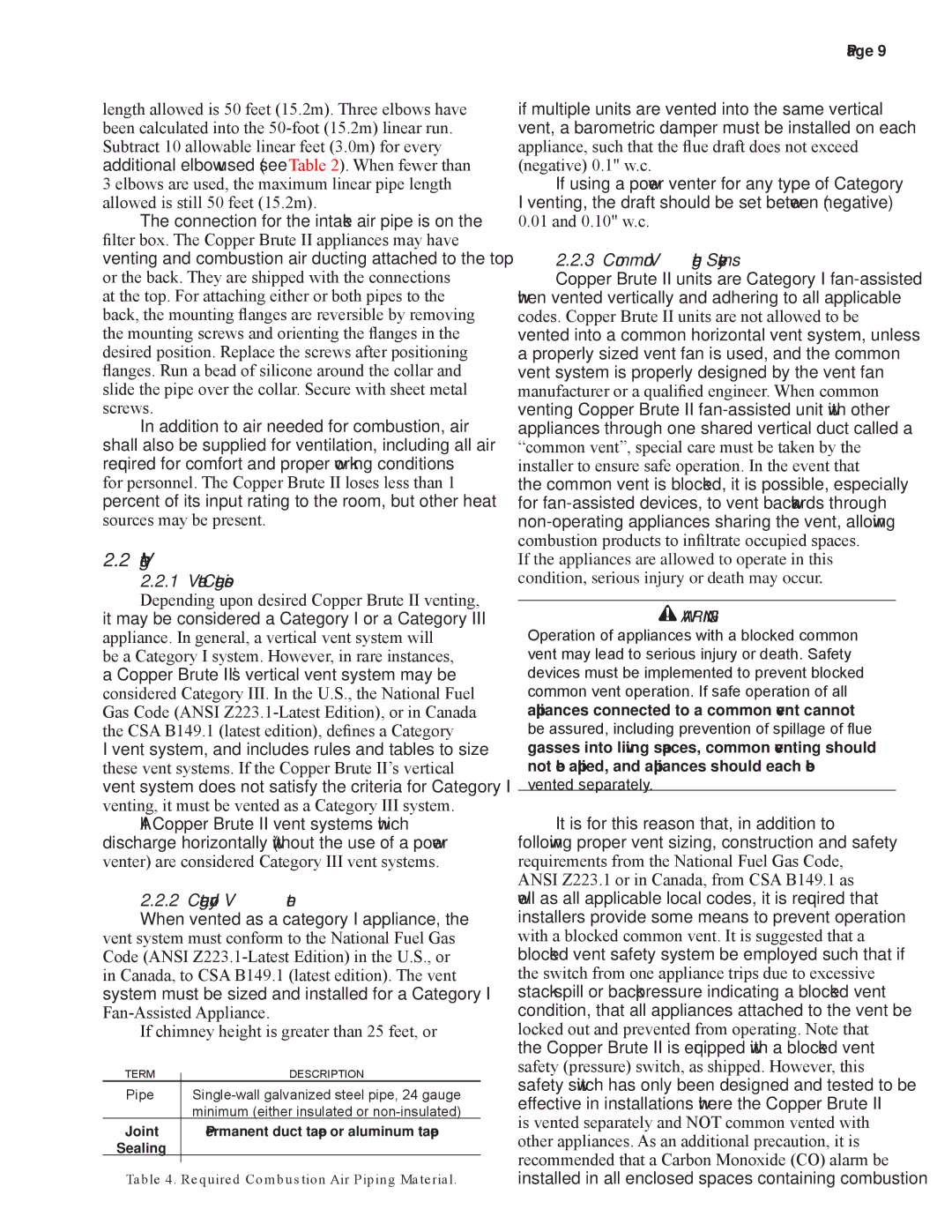

TERM |

| DESCRIPTION |

| ||

Pipe |

| |

|

| minimum (either insulated or |

Joint |

| Permanent duct tape or aluminum tape |

Sealing |

|

|

|

|

|

Table 4. Required Combustion Air Piping Material.

if multiple units are vented into the same vertical vent, a barometric damper must be installed on each appliance, such that the flue draft does not exceed (negative) 0.1" w.c.

If using a power venter for any type of Category I venting, the draft should be set between (negative) 0.01 and 0.10" w.c.

2.2.3 Common Venting Systems

Copper Brute II units are Category I

If the appliances are allowed to operate in this condition, serious injury or death may occur.

![]() WARNING

WARNING

Operation of appliances with a blocked common vent may lead to serious injury or death. Safety devices must be implemented to prevent blocked common vent operation. If safe operation of all appliances connected to a common vent cannot be assured, including prevention of spillage of flue gasses into living spaces, common venting should not be applied, and appliances should each be vented separately.

It is for this reason that, in addition to following proper vent sizing, construction and safety requirements from the National Fuel Gas Code, ANSI Z223.1 or in Canada, from CSA B149.1 as well as all applicable local codes, it is required that installers provide some means to prevent operation with a blocked common vent. It is suggested that a blocked vent safety system be employed such that if the switch from one appliance trips due to excessive stack spill or backpressure indicating a blocked vent condition, that all appliances attached to the vent be locked out and prevented from operating. Note that the Copper Brute II is equipped with a blocked vent safety (pressure) switch, as shipped. However, this safety switch has only been designed and tested to be effective in installations where the Copper Brute II is vented separately and NOT common vented with other appliances. As an additional precaution, it is recommended that a Carbon Monoxide (CO) alarm be installed in all enclosed spaces containing combustion