Page 14 | BRADFORD WHITE CORP. |

|

|

|

|

SECTION 4A.

Water Connections —

Copper Brute II Boiler

4A.1 Heating System Piping:

Hot Supply Connections — Boiler

NOTE: This appliance must be installed in a closed pressure system with a minimum of 12 psi (82.7kPa) static pressure at the boiler.

Hot water piping should be supported by suitable hangers or floor stands. Do not support piping with this appliance. Due to expansion and contraction of copper pipe, consideration should be given to the type of hangers used. Rigid hangers may transmit noise through the system resulting from the piping sliding in the hangers. It is recommended that padding be used when rigid hangers are installed. Maintain 1" clearance to combustibles for hot water pipes.

Pipe the discharge of the relief valve (full size) to a drain or in a manner to prevent injury in the event of pressure relief. Install an air purger, an air vent,

a

Suggested piping diagrams are shown in Figures 4 through 8. These diagrams are meant only as a guide.

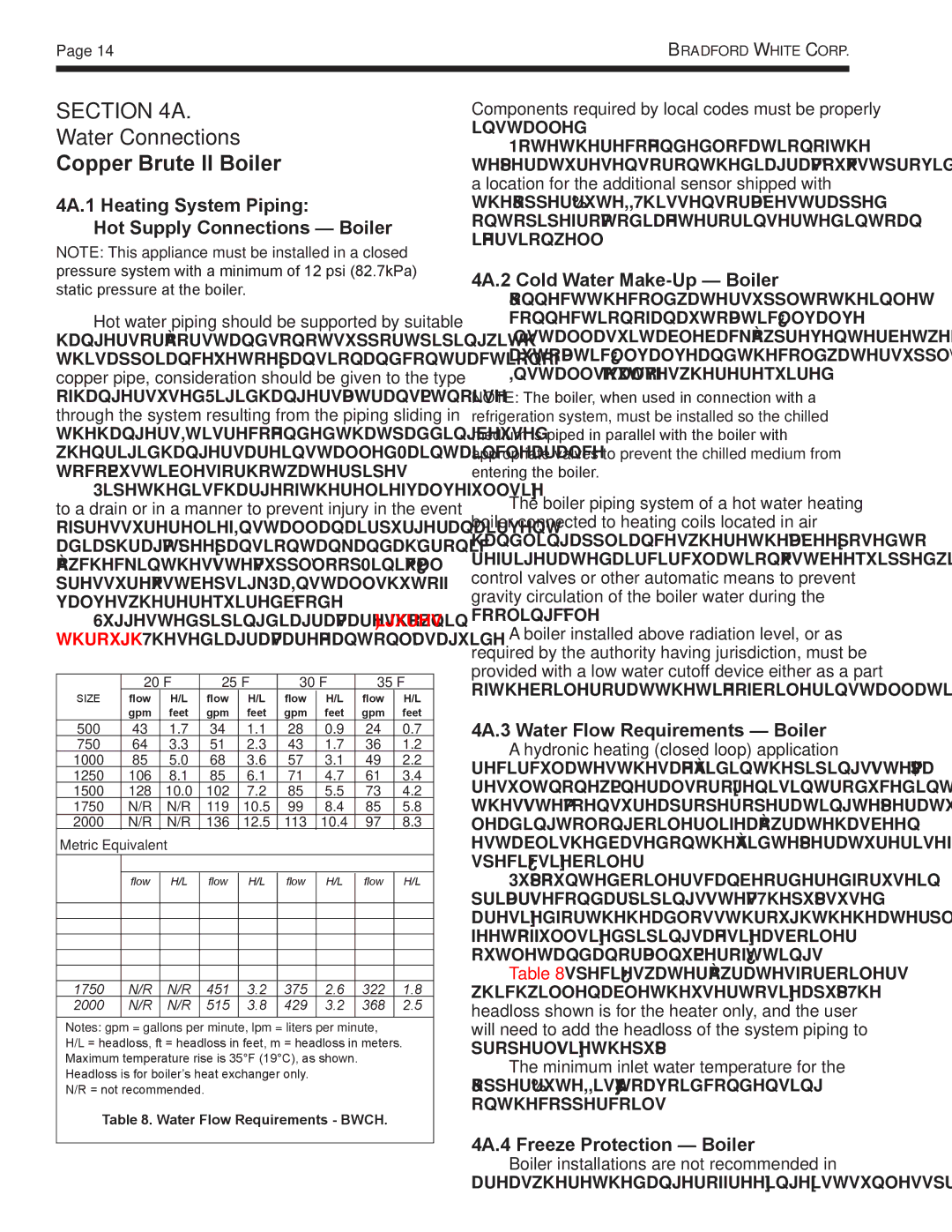

| 20°F | 25°F | 30°F | 35°F | ||||

SIZE | flow | H/L | flow | H/L | flow | H/L | flow | H/L |

| gpm | feet | gpm | feet | gpm | feet | gpm | feet |

500 | 43 | 1.7 | 34 | 1.1 | 28 | 0.9 | 24 | 0.7 |

750 | 64 | 3.3 | 51 | 2.3 | 43 | 1.7 | 36 | 1.2 |

1000 | 85 | 5.0 | 68 | 3.6 | 57 | 3.1 | 49 | 2.2 |

1250 | 106 | 8.1 | 85 | 6.1 | 71 | 4.7 | 61 | 3.4 |

1500 | 128 | 10.0 | 102 | 7.2 | 85 | 5.5 | 73 | 4.2 |

1750 | N/R | N/R | 119 | 10.5 | 99 | 8.4 | 85 | 5.8 |

2000 | N/R | N/R | 136 | 12.5 | 113 | 10.4 | 97 | 8.3 |

Metric Equivalent |

|

|

|

|

|

| ||

| 11°C | 14°C | 17°C | 19°C | ||||

SIZE | flow | H/L | flow | H/L | flow | H/L | flow | H/L |

| lpm | m | lpm | m | lpm | m | lpm | m |

500 | 161 | 0.5 | 129 | 0.3 | 107 | 0.3 | 92 | 0.2 |

750 | 241 | 1.0 | 193 | 0.7 | 161 | 0.5 | 138 | 0.4 |

1000 | 321 | 1.5 | 257 | 1.1 | 214 | 0.9 | 184 | 0.7 |

1250 | 401 | 2.5 | 322 | 1.9 | 269 | 1.4 | 231 | 1.0 |

1500 | 483 | 3.0 | 386 | 2.2 | 322 | 1.7 | 276 | 1.3 |

1750 | N/R | N/R | 451 | 3.2 | 375 | 2.6 | 322 | 1.8 |

2000 | N/R | N/R | 515 | 3.8 | 429 | 3.2 | 368 | 2.5 |

|

|

|

|

|

|

|

|

|

Notes: gpm = gallons per minute, lpm = liters per minute, H/L = headloss, ft = headloss in feet, m = headloss in meters. Maximum temperature rise is 35°F (19°C), as shown. Headloss is for boiler’s heat exchanger only.

N/R = not recommended.

Table 8. Water Flow Requirements - BWCH.

Components required by local codes must be properly installed.

Note the recommended location of the temperature sensor on the diagrams; you must provide a location for the additional sensor shipped with

the Copper Brute II. This sensor may be strapped onto pipe from 1" to 4" diameter, or inserted into an immersion well.

4A.2 Cold Water Make-Up — Boiler

1.Connect the cold water supply to the inlet connection of an automatic fill valve.

2.Install a suitable back flow preventer between the automatic fill valve and the cold water supply.

3.Install shut off valves where required.

NOTE: The boiler, when used in connection with a refrigeration system, must be installed so the chilled medium is piped in parallel with the boiler with appropriate valves to prevent the chilled medium from entering the boiler.

The boiler piping system of a hot water heating boiler connected to heating coils located in air handling appliances where they may be exposed to refrigerated air circulation must be equipped with flow control valves or other automatic means to prevent gravity circulation of the boiler water during the cooling cycle.

A boiler installed above radiation level, or as required by the authority having jurisdiction, must be provided with a low water cutoff device either as a part of the boiler or at the time of boiler installation.

4A.3 Water Flow Requirements — Boiler

A hydronic heating (closed loop) application

Table 8 specifies water flow rates for boilers, which will enable the user to size a pump. The headloss shown is for the heater only, and the user will need to add the headloss of the system piping to properly size the pump.

The minimum inlet water temperature for the Copper Brute II is 120°F (49°C) to avoid condensing on the copper coils.

4A.4 Freeze Protection — Boiler

Boiler installations are not recommended in

areas where the danger of freezing exists unless proper