Figure

![]() 1250, 1500, 1750 & 2000

1250, 1500, 1750 & 2000

COPPER

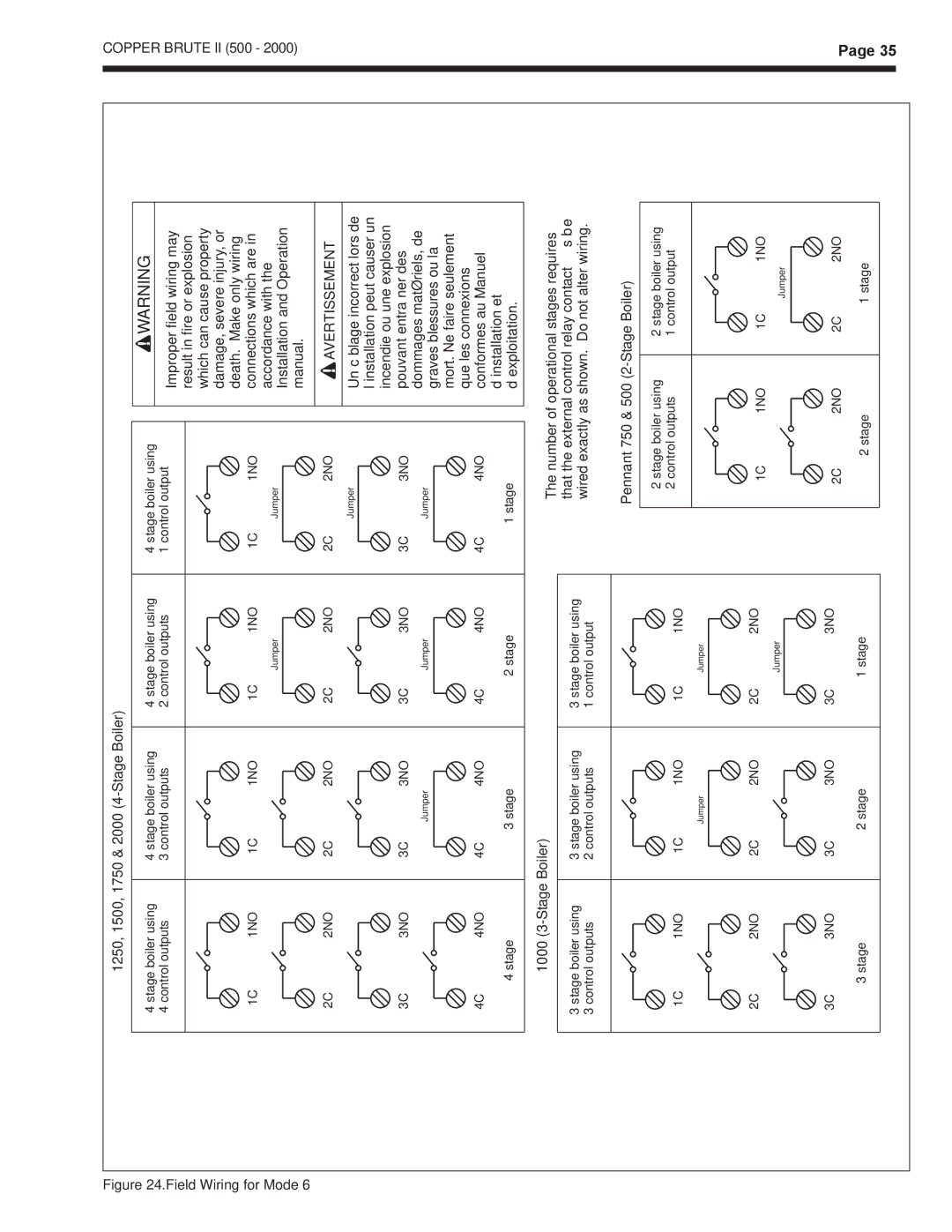

24. Field Wiring for Mode 6.

4 stage boiler using | 4 stage boiler using | 4 stage boiler using | 4 stage boiler using |

4 control outputs | 3 control outputs | 2 control outputs | 1 control output |

1C | 1NO | 1C | 1NO | 1C | 1NO | 1C | 1NO |

|

|

|

|

| Jumper |

| Jumper |

2C | 2NO | 2C | 2NO | 2C | 2NO | 2C | 2NO |

|

|

|

|

|

|

| Jumper |

3C | 3NO | 3C | 3NO | 3C | 3NO | 3C | 3NO |

|

|

| Jumper |

| Jumper |

| Jumper |

4C | 4NO | 4C | 4NO | 4C | 4NO | 4C | 4NO |

| 4 stage |

| 3 stage |

| 2 stage |

| 1 stage |

![]() WARNING

WARNING

Improper field wiring may result in fire or explosion which can cause property damage, severe injury, or death. Make only wiring connections which are in accordance with the Installation and Operation manual.

AVERTISSEMENT

AVERTISSEMENT

Un câblage incorrect lors de l’installation peut causer un incendie ou une explosion pouvant entraîner des dommages matériels, de graves blessures ou la mort. Ne faire seulement que les connexions conformes au Manuel d’installation et d’exploitation.

BRUTE II (500 - 2000)

![]() 1000

1000

3 stage boiler using | 3 stage boiler using | 3 stage boiler using |

3 control outputs | 2 control outputs | 1 control output |

1C | 1NO | 1C | 1NO | 1C | 1NO |

|

|

| Jumper |

| Jumper |

2C | 2NO | 2C | 2NO | 2C | 2NO |

|

|

|

|

| Jumper |

3C | 3NO | 3C | 3NO | 3C | 3NO |

| 3 stage |

| 2 stage |

| 1 stage |

The number of operational stages requires that the external control relay contacts be wired exactly as shown. Do not alter wiring.

Pennant 750 & 500

2 stage boiler using | 2 stage boiler using |

2 control outputs | 1 control output |

1C | 1NO | 1C | 1NO |

|

|

| Jumper |

2C | 2NO | 2C | 2NO |

| 2 stage |

| 1 stage |

Page 35