COPPER BRUTE II (500 - 2000) | Page 15 |

|

|

|

|

COLD WATER

SYSTEM

RETURN

CC

SYSTEM PUMP | SYSTEM | |

SUPPLY | ||

|

PUMP LOCATION FOR

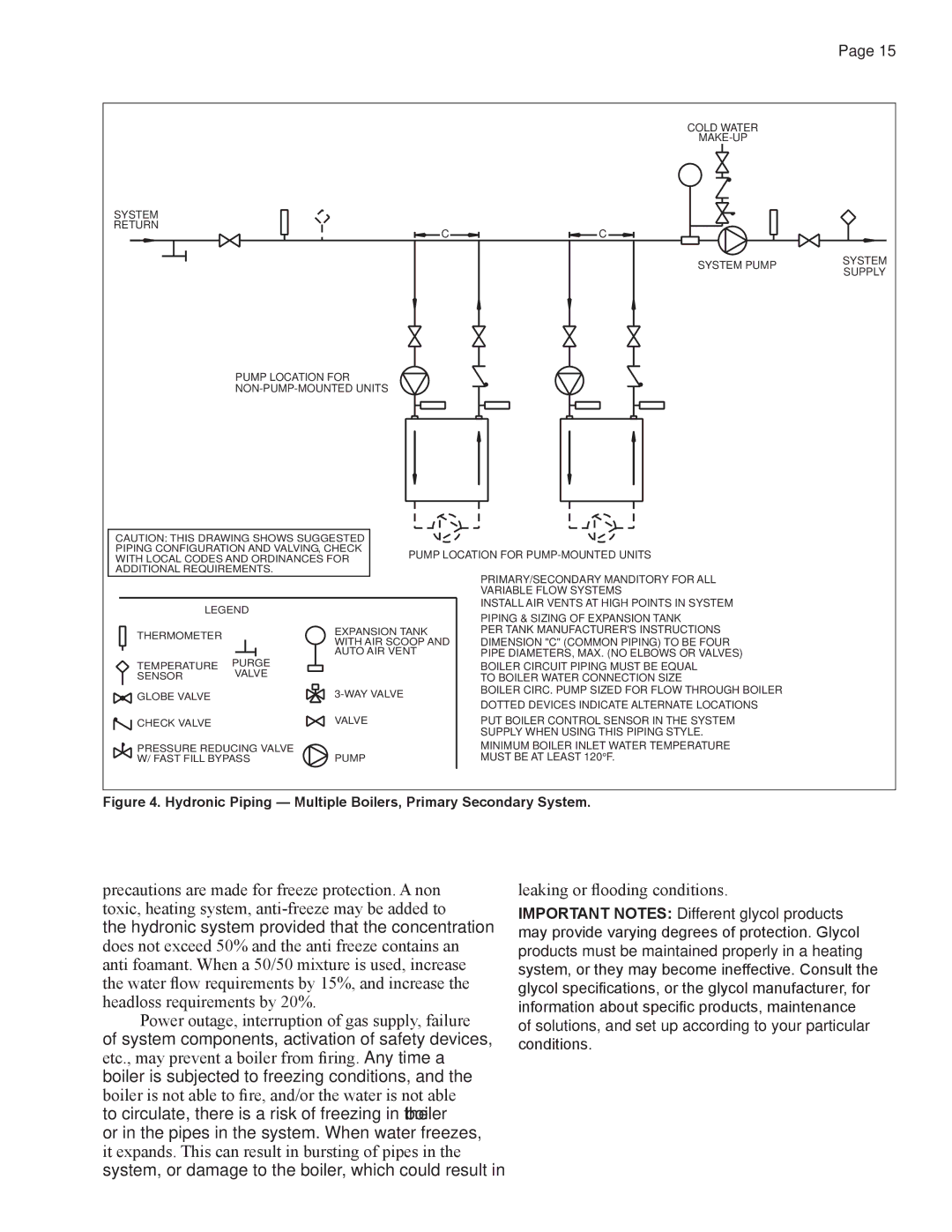

CAUTION: THIS DRAWING SHOWS SUGGESTED |

| |

PIPING CONFIGURATION AND VALVING, CHECK | PUMP LOCATION FOR | |

WITH LOCAL CODES AND ORDINANCES FOR | ||

| ||

ADDITIONAL REQUIREMENTS. |

| |

| PRIMARY/SECONDARY MANDITORY FOR ALL | |

| VARIABLE FLOW SYSTEMS | |

LEGEND | INSTALL AIR VENTS AT HIGH POINTS IN SYSTEM | |

PIPING & SIZING OF EXPANSION TANK | ||

|

THERMOMETER | EXPANSION TANK | PER TANK MANUFACTURER'S INSTRUCTIONS | |

WITH AIR SCOOP AND | DIMENSION "C" (COMMON PIPING) TO BE FOUR | ||

| |||

| AUTO AIR VENT | PIPE DIAMETERS, MAX. (NO ELBOWS OR VALVES) | |

TEMPERATURE | PURGE | BOILER CIRCUIT PIPING MUST BE EQUAL | |

VALVE | |||

SENSOR | TO BOILER WATER CONNECTION SIZE | ||

| |||

GLOBE VALVE | BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER | ||

| |||

| DOTTED DEVICES INDICATE ALTERNATE LOCATIONS | ||

|

|

CHECK VALVE | VALVE |

| |

PRESSURE REDUCING VALVE |

|

W/ FAST FILL BYPASS | PUMP |

PUT BOILER CONTROL SENSOR IN THE SYSTEM SUPPLY WHEN USING THIS PIPING STYLE.

MINIMUM BOILER INLET WATER TEMPERATURE MUST BE AT LEAST 120°F.

Figure 4. Hydronic Piping — Multiple Boilers, Primary Secondary System.

precautions are made for freeze protection. A non toxic, heating system,

Power outage, interruption of gas supply, failure of system components, activation of safety devices, etc., may prevent a boiler from firing. Any time a boiler is subjected to freezing conditions, and the boiler is not able to fire, and/or the water is not able to circulate, there is a risk of freezing in the boiler or in the pipes in the system. When water freezes, it expands. This can result in bursting of pipes in the system, or damage to the boiler, which could result in

leaking or flooding conditions.

IMPORTANT NOTES: Different glycol products may provide varying degrees of protection. Glycol products must be maintained properly in a heating system, or they may become ineffective. Consult the glycol specifications, or the glycol manufacturer, for information about specific products, maintenance of solutions, and set up according to your particular conditions.