Page 42 | BRADFORD WHITE CORP. |

|

|

|

|

6.4 Advanced Topics

For most installations, Section 6.3 provides all the information required to set up the Copper Brute

IIboiler, and this section should be skipped. Continue setup in Section 6.5.

This section provides definitions of the pro- gramming parameters, advanced programming topics, and other information that may be of interest.

Advanced programming mode allows the installer to set the temperature control for proportional staging. In advanced programming mode, the interstage differential, interstage delay, interstage on and off delay, and minimum time on and off are all set manually.

NOTE: Advanced programming mode is not required in most applications, and is intended for advanced installers only.

To enter advanced programming mode, remove the bezel on the temperature control by pulling out at the bottom. Remove the small phillips head screw to access the dip switch. The dip switch is mounted on a circuit board. Locate the letter “A” on the circuit board and slide the corresponding dip switch toward the letter “A”. The default setting of this dip switch is toward the OFF lettering on the circuit board.

6.4.1 Differential

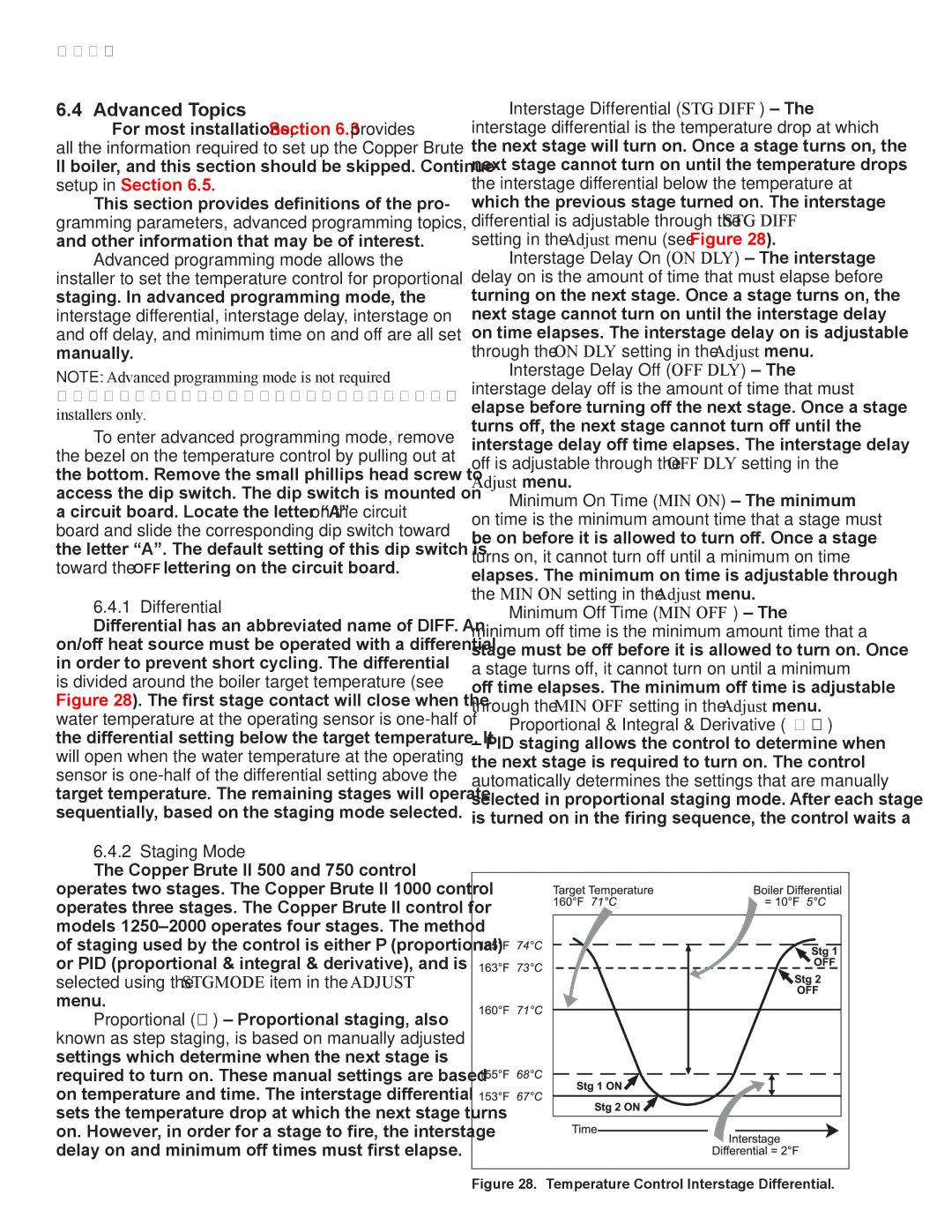

Differential has an abbreviated name of DIFF. An on/off heat source must be operated with a differential in order to prevent short cycling. The differential

is divided around the boiler target temperature (see Figure 28). The first stage contact will close when the water temperature at the operating sensor is

6.4.2 Staging Mode

The Copper Brute II 500 and 750 control operates two stages. The Copper Brute II 1000 control operates three stages. The Copper Brute II control for models

Proportional (P) – Proportional staging, also known as step staging, is based on manually adjusted settings which determine when the next stage is required to turn on. These manual settings are based on temperature and time. The interstage differential sets the temperature drop at which the next stage turns on. However, in order for a stage to fire, the interstage delay on and minimum off times must first elapse.

Interstage Differential (STG DIFF) – The interstage differential is the temperature drop at which the next stage will turn on. Once a stage turns on, the next stage cannot turn on until the temperature drops the interstage differential below the temperature at which the previous stage turned on. The interstage differential is adjustable through the STG DIFF setting in the Adjust menu (see Figure 28).

Interstage Delay On (ON DLY) – The interstage delay on is the amount of time that must elapse before turning on the next stage. Once a stage turns on, the next stage cannot turn on until the interstage delay on time elapses. The interstage delay on is adjustable through the ON DLY setting in the Adjust menu.

Interstage Delay Off (OFF DLY) – The interstage delay off is the amount of time that must elapse before turning off the next stage. Once a stage turns off, the next stage cannot turn off until the interstage delay off time elapses. The interstage delay off is adjustable through the OFF DLY setting in the Adjust menu.

Minimum On Time (MIN ON) – The minimum on time is the minimum amount time that a stage must be on before it is allowed to turn off. Once a stage turns on, it cannot turn off until a minimum on time elapses. The minimum on time is adjustable through the MIN ON setting in the Adjust menu.

Minimum Off Time (MIN OFF) – The minimum off time is the minimum amount time that a stage must be off before it is allowed to turn on. Once a stage turns off, it cannot turn on until a minimum off time elapses. The minimum off time is adjustable through the MIN OFF setting in the Adjust menu.

Proportional & Integral & Derivative (PID)

–PID staging allows the control to determine when the next stage is required to turn on. The control automatically determines the settings that are manually selected in proportional staging mode. After each stage is turned on in the firing sequence, the control waits a